Roller machines are versatile tools used in many industries, including metalworking, woodworking, and plastic processing. They are essential for creating curved shapes, profiles, and sections from flat sheets or plates. However, purchasing a roller machine can be a significant investment, and finding the best deals can be a challenge. In this post, we will provide tips and tricks for finding affordable roller machines without compromising on quality or performance. Whether you’re a small business or a large manufacturer, this guide will help you make informed decisions when investing in roller machines.

Introduction to Roller Machines

Roller machines are tools used to bend, curve, or form materials into various shapes. They consist of a set of rollers that apply pressure to the material, causing it to deform or stretch. Roller machines are used in various industries, including metalworking, woodworking, and plastic processing.

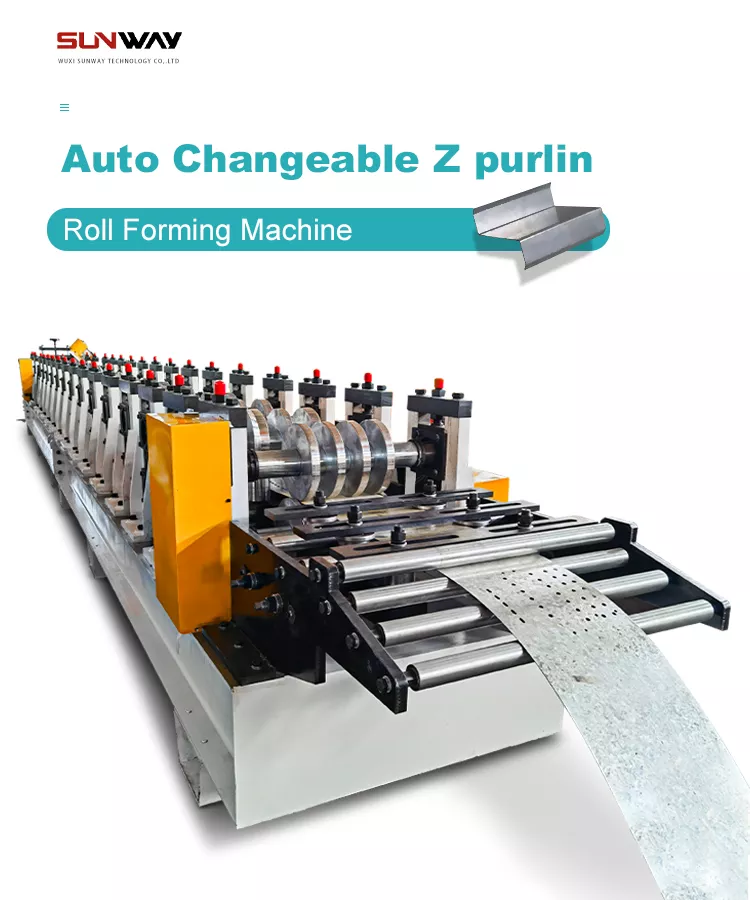

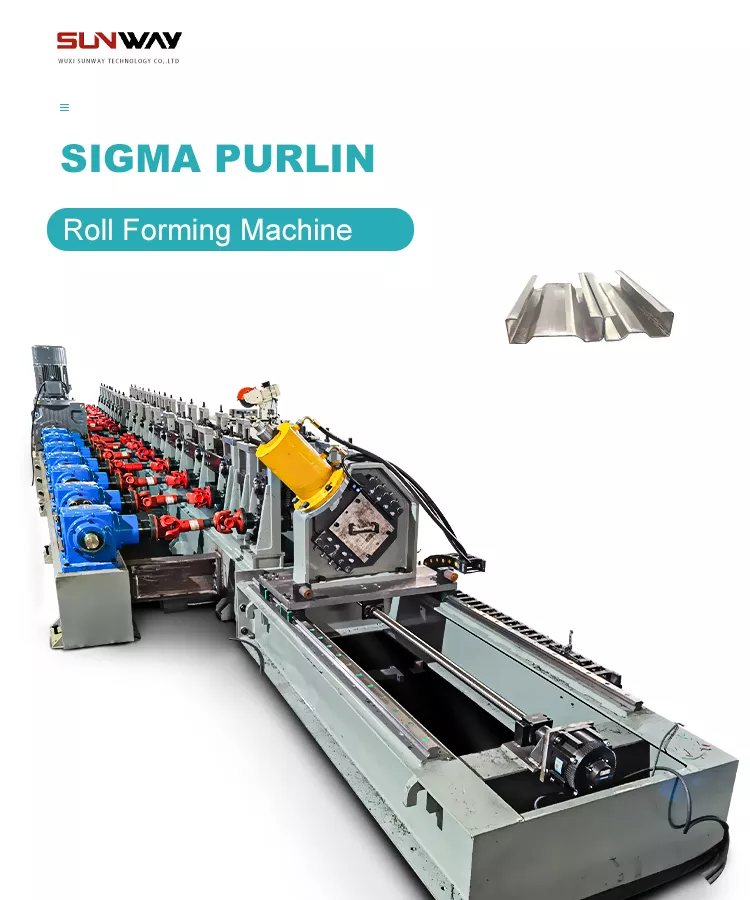

In metalworking, the machines are used to create curved or formed sections from flat metal sheets or plates. This process is called roll forming, and it is used in various applications, including building construction, automotive manufacturing, and appliance production.

In woodworking, the machines are used to create curved or rounded edges on wood panels, as well as to shape wood into various profiles and sections.

In plastic processing, the machines are used to produce plastic sheets, films, and tubes by extruding, calendering, or laminating the plastic material.

Roller machines come in various types, including plate rollers, profile rollers, section rollers, and ring rollers. Each type of machine is designed to meet specific applications and requirements.

Types of Roller Machines

There are several types of roller machines available, each designed for specific applications. Here are some of the most common types of roller machines:

- Plate Rollers: Plate rollers are used for bending large metal sheets or plates into curved shapes. They can handle sheets of various thicknesses and widths, making them suitable for use in heavy-duty industries such as shipbuilding, aerospace, and bridge construction.

- Profile Rollers: Profile rollers are used to create various shapes and profiles in metal, plastic, or wood materials. They can produce consistent shapes with high accuracy and are used in industries such as construction, furniture making, and automotive manufacturing.

- Section Rollers: Section rollers are designed to form metal sections, such as tubes, channels, and angles. They can produce complex shapes and profiles and are used in industries such as construction, transportation, and industrial machinery.

- Ring Rollers: Ring rollers are used to form metal rings and other circular shapes. They are commonly used in industries such as construction, agriculture, and manufacturing.

Each type of roller machine has its unique features and applications. For example, plate rollers are designed for heavy-duty applications and can handle large sheets or plates. Profile rollers are ideal for creating consistent shapes with high accuracy. Section rollers are designed to form metal sections of various shapes and sizes, while ring rollers are used to create circular shapes. Understanding the different types of roller machines and their applications can help businesses choose the right machine for their needs.

Factors Affecting Roller Machine Prices

-

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Cable Ladder Roll Forming Machine

Cable Ladder Roll Forming Machine -

PV Mounting Bracket C Shape Profile Roll Forming Machine

PV Mounting Bracket C Shape Profile Roll Forming Machine -

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine -

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile)

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile) -

PV Mounting Bracket Z Shape Profile Roll Forming Machine

PV Mounting Bracket Z Shape Profile Roll Forming Machine -

Solar mounting strut channel roll forming machine

Solar mounting strut channel roll forming machine -

Strut Channel Roll Forming Machine

Strut Channel Roll Forming Machine

The price of a roller machine can vary significantly based on several factors. Here are some of the most significant factors that impact roller machine prices:

- Machine Type: The type of roller machine is one of the most significant factors affecting the price. Plate rollers tend to be more expensive than profile or section rollers due to their heavy-duty design and larger capacity.

- Capacity: The capacity of the machine is another key factor affecting the price. Machines with a higher capacity and larger working range tend to be more expensive than smaller machines.

- Features: The features included with the machine can also impact the price. For example, a machine with automated controls, variable speed drives, or advanced tooling systems may be more expensive than a basic machine.

- Brand Reputation: The reputation of the brand is also a significant factor in the price of the machine. Established brands with a reputation for quality and reliability tend to command higher prices than lesser-known brands.

- Customization: Customization options can also impact the price of the machine. Customized machines designed to meet specific requirements may cost more than standard machines.

In summary, several factors impact the price of a roller machine, including machine type, capacity, features, brand reputation, and customization options. Understanding these factors can help businesses make informed decisions when investing in roller machines and find the best value for their money.

Tips for Finding Affordable Roller Machines

Purchasing a roller machine can be a significant investment for any business, especially for small businesses with limited budgets. However, there are several ways to find affordable roller machines without compromising on quality or performance. Here are some tips and tricks for finding affordable roller machines:

- Buy Used or Refurbished Machines: One of the most cost-effective ways to purchase a roller machine is to buy a used or refurbished machine. Used machines can be found through online marketplaces, auctions, or through local dealerships. Refurbished machines have been restored to like-new condition and can offer significant cost savings compared to new machines.

- Search for Clearance Sales: Many suppliers offer clearance sales or end-of-season discounts on the machines. These sales can offer significant savings, but it’s important to act quickly as these deals may be limited in quantity.

- Negotiate with Suppliers: Negotiating with suppliers can also help businesses find affordable machines. By discussing the specifics of the machine and the volume of the purchase, businesses may be able to negotiate a lower price with the supplier.

- Compare Prices from Different Suppliers: It’s important to compare prices from different suppliers to find the best value for the machine. By researching different suppliers and requesting quotes, businesses can find the best deals on the machines.

- Check for Financing Options: Financing options, such as leasing or rent-to-own, can help businesses afford machines without paying the full cost upfront. It’s important to compare financing options from different providers and choose the option that offers the lowest overall cost.

- Attend Trade Shows: Attending trade shows can also provide an opportunity to find affordable machines. These events offer a chance to see different machines in action, meet suppliers, and potentially negotiate discounts or financing options.

By following these tips and tricks, businesses can find affordable roller machines that meet their specific needs. It’s important to balance cost with quality and choose a supplier with experience, a reputation for quality, and a commitment to customer service. With the right approach, businesses can find the best roller machine deals and improve their bottom line.

In conclusion, finding affordable roller machines requires research, negotiation, and strategic decision-making. Businesses can purchase used or refurbished machines, search for clearance sales, negotiate with suppliers, and compare prices from different providers to find the best deals. Financing options such as leasing and rent-to-own can also help businesses afford roller machines without paying the full cost upfront. It’s important to balance cost with quality and choose a supplier with experience, a reputation for quality, and a commitment to customer service. By following these tips and tricks, businesses can find the best roller machine deals and improve their bottom line.