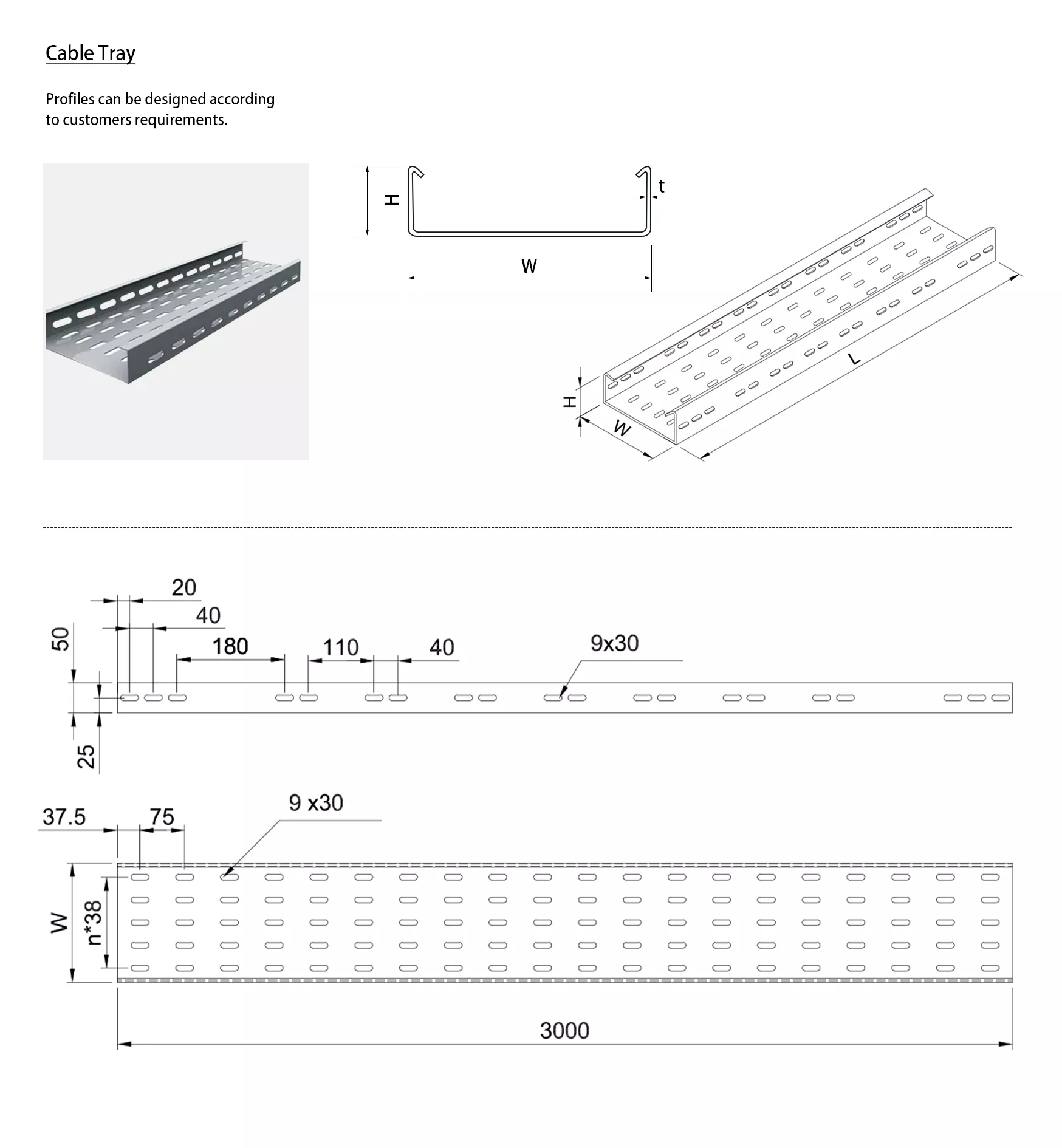

Cable Tray Roll Forming Machine Profile Drawings

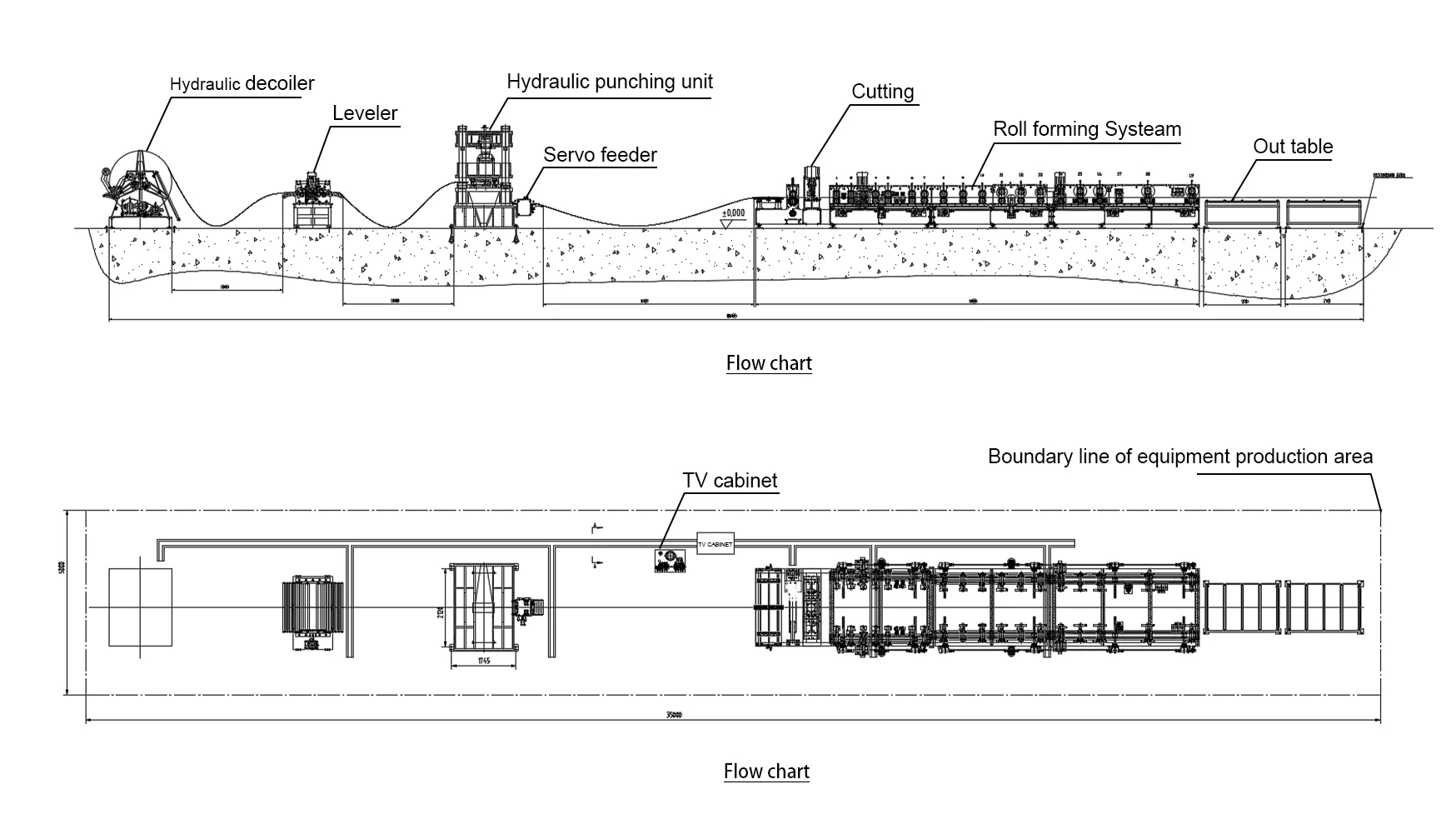

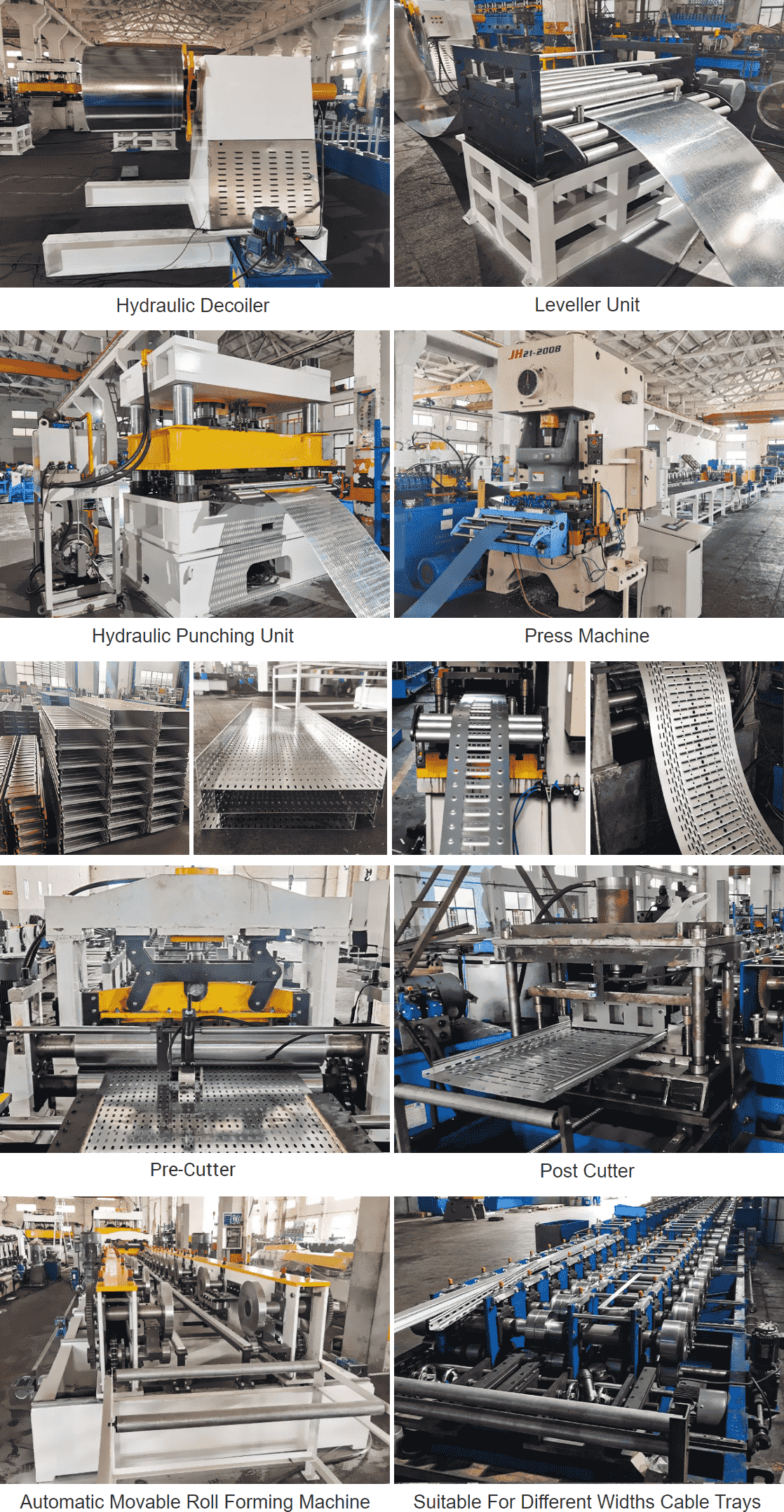

Cable Tray Roll Forming Machine Production Line

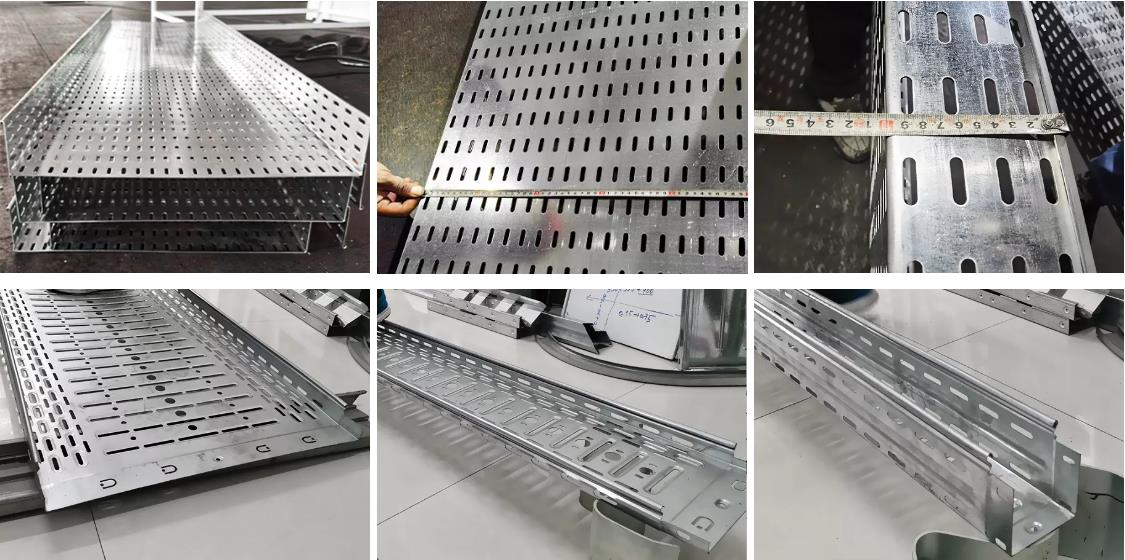

Product Details

Cable Tray Roll Forming Machine Parameters

| Cable Tray Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Steel |

Thickness(MM): 0.6-1.2 or 1-2 even more

|

| B) PPGI | ||

| C) Carbon Steel | ||

| Yield Strength | 250 – 550 Mpa | |

| Tensil Stress | G250 Mpa-G550 Mpa | |

| Cable Tray Size | 50/100-600mm Or According To Profile Drawings | |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Punching System | Hydraulic Punching Station (Individual) | * Punching Press (Optional) |

| Forming Station | 20 | * According To Your Profile Drawings |

| Driving System | Chain Drive | * Gearbox drive (Optional) |

| Machine Structure | Cantilever Type Adjust The Width And Height Freely | * Forged Iron station (Optional) |

| Forming Speed | 10-20 (M/MIN) | * Or According To Your Profile Drawings |

| Rollers’ Material | GCr 15 | * Cr12Mov(Optional) |

| Cutting System | Post-cutting | * Pre-cutting (Optional) |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| PLC Brand | Panasonic | * Siemens (Optional) |

| Power Supply | 380V 50Hz 3ph | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

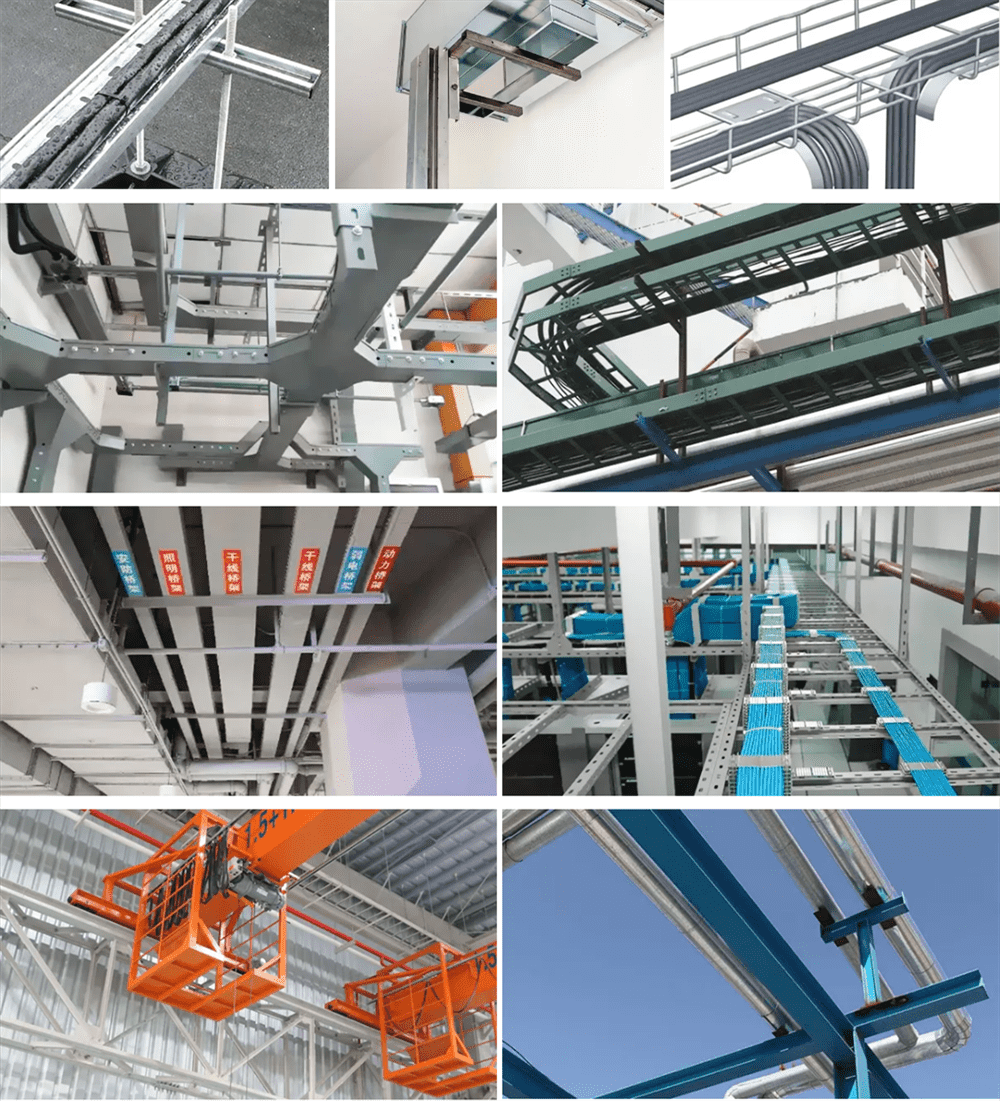

Application

With the features of green, solid, economical, durable, fast easy to install and good-looking, double in roll C-shaped steel photovoltaic bracket and other steel building materials are used more and more widely. It is suitable for various light steel structure construction, shelves, ceiling frames, and so on.

what is cable tray roll forming machine

A cable tray roll forming machine is a specialized industrial machine designed to manufacture cable trays. Cable tray roll forming machine also named cable tray making machine. Cable trays are structural components used in electrical installations to support and organize cables, wires, and other electrical equipment. Cable trays provide a safe and efficient way to route and protect electrical wiring in buildings, industrial facilities, and infrastructure projects.

Here’s an overview of how a cable tray making machine typically works:

- Material Feeding: The machine begins by feeding a metal strip, usually made of galvanized steel or aluminum, into the roll forming line. The strip is often supplied in coil form and is unwound and guided into the machine for further processing.

- Roll Forming: The metal strip passes through a series of rollers and roll forming stations. Each set of rollers gradually shapes the strip into the desired profile of the cable tray. The rollers are specifically designed to create the specific features and dimensions required, such as the sidewalls, rungs, and mounting holes of the cable tray.

- Cutting: Once the metal strip has been fully formed into cable tray sections, a cutting mechanism is employed to separate the

- Hole Punch

- Length Measurement and Stacking: After the cutting and hole punching processes, the cable tray sections are typically measured for length using sensors or measurement devices. The sections are then stacked or collected for packaging or further processing.

Cable tray roll forming machines often feature computer-controlled systems to ensure accurate and consistent shaping of the metal strip. These machines may also have features such as automatic material feeding, adjustable roller sets, and control panels for easy operation and monitoring.

By utilizing a cable tray making machine, manufacturers can efficiently produce high-quality cable trays in large quantities. These cable trays provide a reliable and organized solution for cable management in electrical installations, ensuring safety and ease of maintenance.

does galvanized cable tray making machine belong to cable tray roll forming machine?

Yes, a galvanized cable tray making machine belongs to the category of cable tray roll forming machines. The term “galvanized” refers to the process of coating the metal, typically steel, with a layer of zinc to provide corrosion resistance and durability. Galvanized cable trays are widely used in electrical installations and industrial applications due to their superior protection against rust and environmental conditions.

A galvanized cable tray making machine is specifically designed to manufacture cable trays using galvanized steel strips. The machine follows the same basic principles as a cable tray roll forming machine, which includes feeding the metal strip, roll forming the desired profile of the cable tray, cutting and punching holes or slots, and length measurement and stacking.

The key distinction of a galvanized cable tray making machine is that it is equipped to handle galvanized steel strips and ensure the proper coating of zinc during the manufacturing process. This may involve additional steps such as surface cleaning or zinc coating application to achieve the desired galvanized finish.

top 5 cable tray roll forming machine factory in China

- WUXI SUNWAY MACHINERY CO., LTD is a professional manufacturer and exporter that are concerned with the design, development and production of cold roll forming machines. All products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world, such as Asia, Africa, Europe, South America, and Australia and so on. It has gained a global sales network.

- Shanghai Wright Bros Technology Co., Ltd: They specialize in the design and production of roll forming machines for various applications, including cable tray roll forming machines. They offer a range of customized solutions for different types and sizes of cable trays.

- Wuxi Suhang Machinery Manufacturing Co., Ltd: With years of experience, Suhang Machinery is a reputable manufacturer of roll forming machines, including those for cable trays. They provide reliable and efficient machines tailored to customer specifications.

- Jiangsu Lebron Machinery Technology Co., Ltd: Lebron Machinery is known for its expertise in roll forming machines, including cable tray roll forming machines. They offer advanced technologies and solutions for cable tray production, with a focus on quality and customer satisfaction.

- Hangzhou Roll Forming Machinery Co., Ltd: They have been manufacturing roll forming machines for more than 15 years and provide a range of solutions for cable tray production. Their machines are known for their precision, durability, and customization options.

Reviews

There are no reviews yet.