What is A PV Mounting Bracket C Shape Profile Roll Forming Machine?

PV Mounting Bracket C Shape Profile Roll Forming Machine, also known as photovoltaic (PV) rack roll forming machine, is a state-of-the-art equipment used to mount, brace, support, and connect lightweight structural loads in Solar or Energy fields. It is an essential tool in the manufacturing of C-shaped profiles (C channels) with a thickness ranging from 1.5-2.5mm, and even up to 3mm.

The machine is a high-performance assembly line that includes a hydraulic uncoiler, servo feeder, press machine/ individual punch unit for punching holes, roll former, servo tracking cutter, and electrical & hydraulic system. Compared with C purline used on steel structure, this solar mounting C shape profile requires a machine with higher precision, speed, and accurate punching. Therefore, this line is built with a heavier and stronger structure, and its speed is much higher to meet the demand of huge mass production.

The raw materials used for this machine can be Hot-rolled and cold rolled steel, Hot-dip galvanized sheet, Pre Galvanized Steel, Mill (Plain/Black) Steel, etc. Additionally, this machine is versatile and can produce solid channel, slotted channel, half slotted channel, long slotted channel, punched channel, punched and slotted channel, etc. We customize our solutions according to customers’ drawings, tolerance, and budget, offering professional one-to-one service that is adaptable to your every need.

At SUNWAY Machinery, we are committed to providing high-quality products, and our PV Mounting Bracket C Shape Profile Roll Forming Machine is no exception. With our advanced technology and years of experience, we ensure that our equipment produces perfectly functional profiles that meet your requirements. If you have any further questions or need assistance, please do not hesitate to contact us.

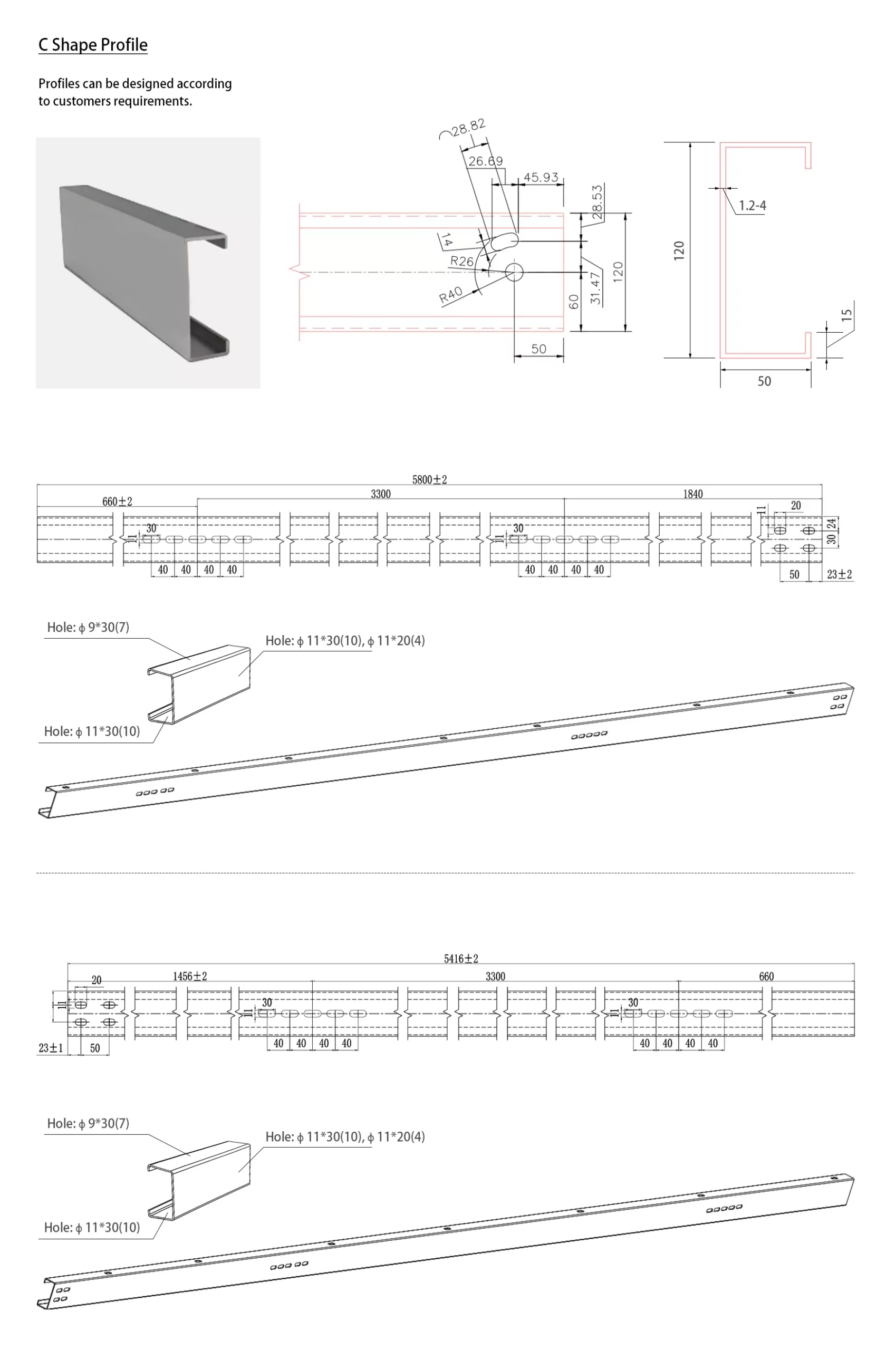

PV Mounting Bracket C Shape Profile Roll Forming Machine Profile Drawings

Our PV Mounting Bracket C Shape Profile Roll Forming Machine Profile Drawings are designed to meet the needs of manufacturers in the Solar and Energy fields. The product line is capable of producing C-shaped profiles with a thickness ranging from 1.5-2.5mm, up to 3mm. This makes it ideal for mounting, bracing, supporting, and connecting lightweight structural loads.

Our machine is built using advanced technology and processes, and the product line includes a hydraulic uncoiler, servo feeder, press machine/individual punch unit, roll former, servo tracking cutter, and electrical & hydraulic system. This ensures high precision, speed, and accuracy in punching and forming the C-shaped profiles.

At SUNWAY Machinery, we offer customized solutions to cater to your specific drawing, tolerance, and budget requirements. Our machine is versatile and can also produce a range of profiles, including solid channel, slotted channel, half slotted channel, long slotted channel, punched channel, punched and slotted channel, and more.

We pride ourselves on offering high-quality equipment and excellent after-sales service, and we always strive to ensure our customers’ satisfaction. Whether you are looking for mass production or customized solutions, our PV Mounting Bracket C Shape Profile Roll Forming Machine Profile Drawings will deliver perfectly functional profiles that meet your needs.

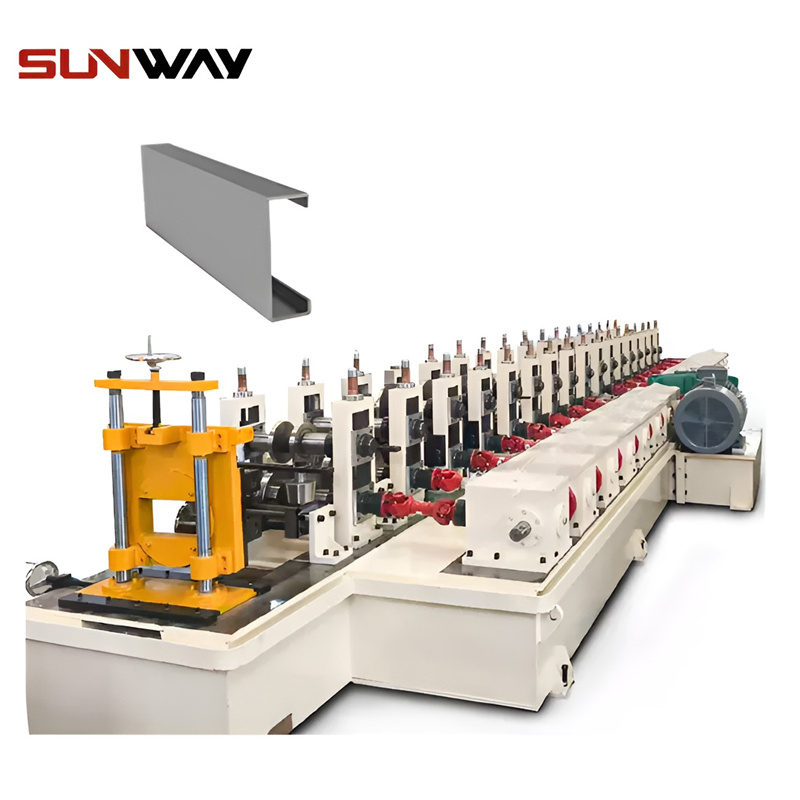

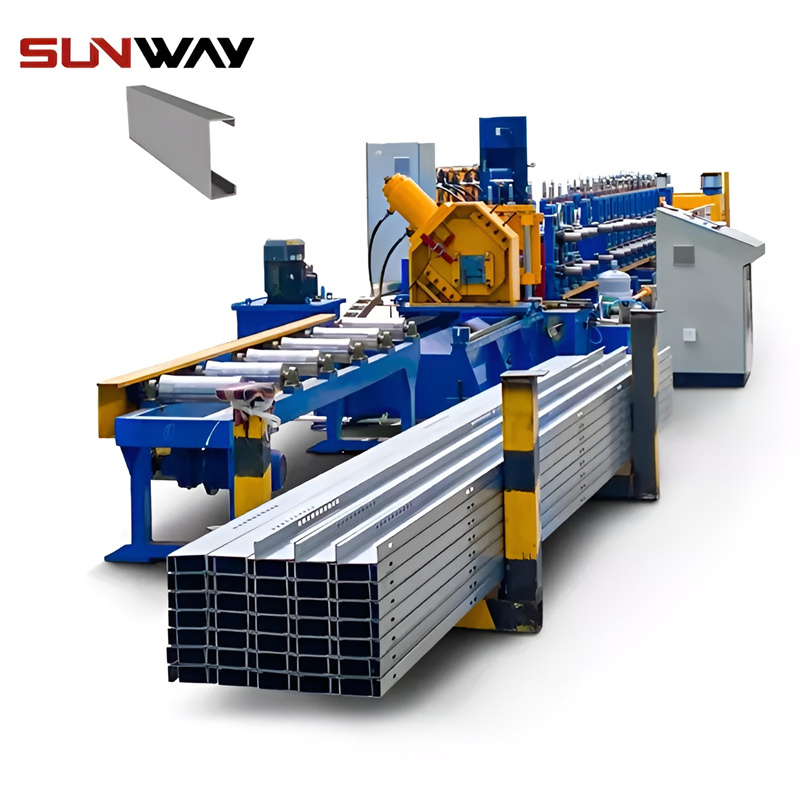

PV Mounting Bracket C Shape Profile Roll Forming Machine Production Line

As an independent online seller with over five years of experience in selling machinery products and knowledge of Google SEO marketing rules, I am pleased to introduce the PV Mounting Bracket C Shape Profile Roll Forming Machine Production Line to you. Our production line is a high-performance machine used for manufacturing C-shaped steel in the solar and energy fields. We offer two types of production lines, one with a press machine for punching unit and the other with an individual hydraulic punching unit.

For the production line with a press machine for punching unit, the two-in-one decoiler and leveler ensures smooth and accurate feeding of the material, while the press machine is responsible for punching and forming. The storage rack provides a temporary storage place for the finished product before it is transported to the next process. The roll forming system is used to shape the C-shaped steel into the required profile, while the servo tracking cutting ensures precise and accurate cutting of the steel. Finally, the out table provides a platform for the finished product to be collected.

With the production line with an individual hydraulic punching unit, the servo feeder ensures smooth and accurate feeding of the material, while the hydraulic punching machine is used for punching. The storage rack provides temporary storage for the finished product before being transported to the next process. The roll forming system is responsible for shaping the C-shaped steel into the required profile, while the servo tracking cutting ensures precise and accurate cutting of the steel. By adopting an independent punching machine, the production line has higher flexibility and adaptability, allowing for adjustments according to different customer requirements. This results in higher punching efficiency and accuracy, which in turn improves production efficiency and quality.

Both production lines are designed to meet various customer needs and provide efficient and precise punching and forming of C-shaped steel. They offer different advantages depending on the customer’s specific requirements. No matter which production line is chosen, customers can expect high-quality products and efficient after-sales service to meet their needs.

No matter which production line you choose, our machine can produce high-quality C-shaped steel. We also provide high-quality after-sales service to help you solve any problems and meet any needs. Our customer service team has received professional training and can quickly respond to customer questions and needs, providing satisfactory solutions.

PV Mounting Bracket C Shape Profile Roll Forming Machine Details

Our machine is designed to provide efficient and precise punching and forming of C-shaped steel, and it comes with several important features.

The hydraulic decoiler ensures smooth and accurate feeding of the material, while the 2 in 1 hydraulic decoiler combines the functions of an uncoiler and leveler. The press machine for punching holes allows for efficient and precise punching, and customers can also choose to use the individual hydraulic punching unit for even higher punching efficiency and accuracy.

The main machine structure with forged cast iron station provides a stable and sturdy foundation for the machine, and it can be driven by either a gearbox or chain drive depending on the size of the machine. The servo tracking hydraulic cutter ensures precise and accurate cutting of the steel, and the machine can even operate non-stop for even greater efficiency. Customers can also choose to use the hydraulic cutter that stops the machine, which is optional.

All of these features work together to provide a high-quality machine that can meet various customer needs.We provide you with high-quality products and after-sales service, making your production more efficient and time-saving.

Product Parameters of PV Mounting Bracket C Shape Profile Roll Forming Machine

| PV Mounting Bracket C Shape Profile Roll Forming Machine | ||

|

Machinable Material

|

A) Hot-rolled And Cold Rolled Steel |

Thickness(MM): 1.5-2.5 or up to 3mm

|

| B) Hot-dip Galvanized Sheet | ||

| C) Pre-Galvanized Steel | ||

| D) Mill (Plain/Black) Steel | ||

| Yield strength | 235 – 345 Mpa | |

| Tensil stress | G250 Mpa-G350 Mpa | |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Punching System : | Hydraulic Punching Station (Individual) | * Punching Press (Optional) |

| Forming Station | 14 – 16 | * According To Your Profile Drawings |

| Main Machine Motor Brand | Reducer + Motor | * Servo Motor (Optional) |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Wall Panel | * Forged Iron station (Optional) |

| Line Forming Speed | 0-15 (M/MIN) | * According To Final Configuation |

| Rollers’ Material | 45# | * GCr 15 (Optional) |

| Cutting System | Post-cutting, Machine Stop To Cut | * Tracking Servo Cutter (Optional) |

| Frequency Changer Brand | Yaskawa | |

| PLC Brand | Panasonic | |

| Power Supply | 380V 50Hz 3ph | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

Application of PV Mounting Bracket C Shape Profile Roll Forming Machine

The PV Mounting Bracket C Shape Profile Roll Forming Machine is widely used in the solar and energy industry for various applications such as mounting, bracing, supporting, and connecting lightweight structural loads. This machine is highly versatile and adaptable, making it suitable for a wide range of industries and applications.

In the solar industry, the machine is commonly used for the production of solar mounting brackets, which are essential components in solar panel installations. These brackets provide the necessary support and stability to keep the panels in place and maximize their energy output. The PV Mounting Bracket C Shape Profile Roll Forming Machine produces high-quality brackets that meet the industry’s strict standards and requirements.

In addition to the solar industry, the machine is also used in other energy-related fields such as wind power, hydroelectric power, and thermal power. It can be used to produce various components and structures that are required in these industries, such as supports, frames, and mounting systems. The machine is highly efficient and precise, making it ideal for large-scale production of these components.

The machine’s versatility and adaptability make it suitable for a wide range of industries, including construction, transportation, and manufacturing. It can produce C-shaped profiles in various sizes and shapes, making it highly versatile and adaptable to different applications.

Our Several customers have reported high levels of satisfaction with the machine’s performance, including its efficiency, accuracy, and ease of use. These customers have reported significant improvements in their production processes and overall business performance since incorporating the machine into their operations.

Overall, our PV Mounting Bracket C Shape Profile Roll Forming Machine is a highly versatile and efficient machine that is widely used in the solar and energy industry, as well as other industries. Its precision, efficiency, and adaptability make it a valuable addition to any production process, and its high-quality results and satisfied customers are a testament to its capabilities.

What is profile roll forming machine?

A profile roll forming machine is a type of industrial machinery used in the metalworking and manufacturing industry. It is designed to continuously bend and shape metal coils into specific profiles or shapes. The process involves passing a strip of metal through a series of roll forming stations, where each station gradually bends and forms the metal into the desired profile.

The machine consists of a series of rollers, also known as roll tooling or roll forming stands, arranged in a sequence. Each set of rollers is responsible for shaping a specific part of the profile. As the metal strip passes through the machine, it is gradually transformed by the action of the rollers, which progressively bend and form the material.

The profile roll forming machine can produce a wide range of profiles with consistent dimensions and high precision. It is commonly used for manufacturing various products such as metal sheets, roofing panels, door frames, window frames, automotive components, and other custom profiles used in construction, industrial applications, and consumer goods.

These machines offer several advantages, including high production speed, low labor requirements, and the ability to produce long continuous profiles with minimal material waste. Additionally, profile roll forming machines can be automated and integrated into production lines, making them efficient for large-scale manufacturing operations.

Overall, profile roll forming machines play a crucial role in the metalworking industry by enabling the efficient and cost-effective production of customized metal profiles with consistent quality and precision.

What is the function of the c shape purlin roll forming machine?

The C shape purlin roll forming machine is specifically designed to produce C-shaped purlins, which are structural components used in building construction. Purlins are horizontal structural members that provide support to the roof or walls of a building. They are typically installed parallel to the primary structural frame and provide stability, load distribution, and attachment points for roof or wall panels.

The function of the C shape purlin roll forming machine is to manufacture C-shaped purlins from coil metal. The machine takes a coil of metal, such as galvanized steel, and passes it through a series of roll forming stations. Each station gradually bends and forms the metal into the specific shape of a C-shaped purlin.

The roll forming process involves feeding the metal coil into the machine, where it is guided through a series of rollers. The rollers are carefully designed to shape and gradually form the metal into the desired C shape. The process typically includes several stations, each responsible for shaping a particular part of the purlin, such as the flanges, lips, and web.

The C shape purlin roll forming machine ensures precise dimensions, consistent quality, and high production speed. It can be customized to produce different sizes and thicknesses of C-shaped purlins to meet specific construction requirements. These purlins are commonly used in various building applications, including industrial buildings, warehouses, commercial structures, and residential projects.

By utilizing a C shape purlin roll forming machine, manufacturers can efficiently produce large quantities of C-shaped purlins with minimal material waste and labor requirements. The resulting purlins are durable, cost-effective, and compatible with various roofing and cladding systems, making them an essential component in modern construction.

What are the main application areas of the C profile steel roll forming machine?

The C profile steel roll forming machine is used to produce C-shaped steel profiles, also known as C channel or C section. These profiles have a distinctive shape resembling the letter “C” and are widely used in various industries and applications. Some of the main application areas of the C profile steel roll forming machine include:

- Building Construction: C profiles are commonly used in building construction for structural purposes. They serve as support beams, purlins, and framework components in the construction of roofs, walls, and floors. C profiles provide strength, stability, and load-bearing capabilities to the building structure.

- Infrastructure Projects: The C profile steel roll forming machine finds application in infrastructure projects such as bridges, highways, tunnels, and railways. C profiles are used for constructing frameworks, support structures, and other load-bearing elements in these projects.

- Industrial Applications: C profiles are utilized in various industrial settings for manufacturing equipment, machinery frames, conveyor systems, and racks. The high strength and versatility of C profiles make them suitable for constructing robust and customized structures to meet specific industrial requirements.

- Electrical and Telecommunication Industries: C profiles are widely used in electrical and telecommunication industries for cable trays, support brackets, and mounting structures. These profiles provide a durable and efficient solution for organizing and supporting cables and electrical components.

- Automotive Industry: C profiles find application in the automotive industry for manufacturing car frames, chassis components, and structural parts. The strength-to-weight ratio of C profiles makes them desirable for enhancing the overall strength and safety of vehicles.

- Solar Panel Mounting Systems: C profiles are commonly employed in solar panel mounting systems. These profiles serve as support rails or frames for mounting solar panels on roofs or in open spaces. The C profile steel roll forming machine enables the production of customized and precise profiles for efficient solar panel installations.

These are just a few examples of the application areas for C profile steel roll forming machines. The versatility, strength, and cost-effectiveness of C profiles make them suitable for a wide range of industries and construction projects. The roll forming machine ensures efficient production of consistent and accurate C profiles to meet the diverse needs of these applications.

Reviews

There are no reviews yet.