In the steel construction industry, C purlins are indispensable. These lightweight yet strong structural components are essential for supporting roofs, walls, and flooring systems across residential, commercial, and industrial buildings. But behind every high-performance C purlin lies a powerful manufacturing solution—the C Purlin Roll Forming Machine. This advanced machine enables manufacturers to produce high-quality C purlins with precision, efficiency, and scalability.

In this guide, we’ll take a deep dive into High-Quality C Purlin Roll Forming Machines, covering their features, applications, pricing, advantages, and why they’re a must-have for steel structure manufacturers. Plus, we’ll introduce you to Wuxi Sunway Machinery, a globally trusted leader in roll-forming equipment, and explore how their innovative machines are redefining excellence in the industry.

What is a C Purlin Roll Forming Machine?

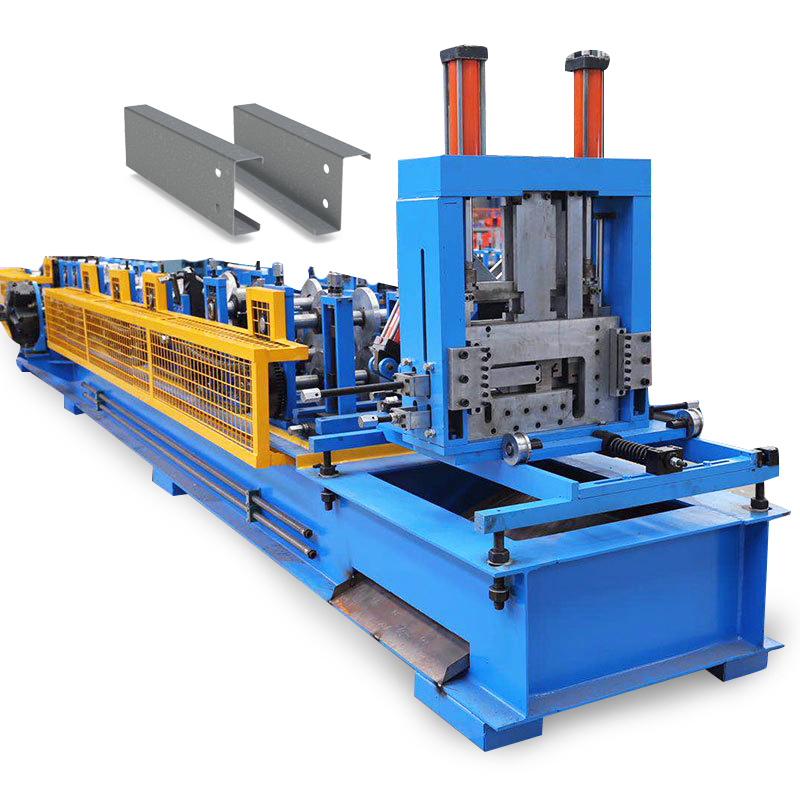

A C Purlin Roll Forming Machine is a specialized piece of equipment used to manufacture C-shaped steel purlins—a vital structural component in construction projects. These machines take flat steel coils and transform them into precise C purlin profiles through a continuous roll-forming process. The result? High-strength, lightweight purlins that are both cost-effective and easy to install.

The machine offers programmable flexibility, allowing manufacturers to produce purlins in various sizes, thicknesses, and lengths to meet diverse project requirements. With fully automated systems and advanced cutting and punching technologies, the C Purlin Roll Forming Machine ensures consistent quality and high production efficiency.

Applications of C Purlins

C purlins are versatile structural components that play a critical role in construction. Here are the key areas where they are used:

1. Roofing Systems

- Use Case: C purlins act as horizontal supports for metal roofing sheets, ensuring durability and load distribution.

2. Wall Framing

- Use Case: These purlins are used as studs and frames for cladding systems, providing strength and alignment to walls.

3. Industrial Sheds and Warehouses

- Use Case: C purlins are widely used in large-span industrial buildings due to their ability to bear heavy loads without adding excessive weight.

4. Agricultural Structures

- Use Case: Barns, silos, and greenhouses rely on C purlins for structural support in roofing and wall systems.

5. Solar Panel Mounting Systems

- Use Case: C purlins provide a sturdy base for solar panel installations, ensuring stability and resistance to environmental stress.

6. Mezzanine Floors

- Use Case: In commercial and industrial buildings, C purlins serve as beams for mezzanine floor structures, offering a lightweight yet strong solution.

Key Features of Wuxi Sunway C Purlin Roll Forming Machines

When it comes to roll-forming technology, Wuxi Sunway Machinery is a name you can trust. Their High-Quality C Purlin Roll Forming Machines are designed to deliver exceptional performance, versatility, and efficiency. Here’s what makes them stand out:

1. Fully Adjustable Profiles

- What It Does: Allows for quick adjustments to produce C purlins in various sizes, including width, height, and thickness.

- Why It’s Important: Eliminates the need for additional tooling, saving time and costs.

2. High-Speed Production

- Performance: Capable of producing 10–20 meters of purlins per minute, depending on the material and design.

- Why It Matters: Increases production efficiency to meet high-demand projects.

3. Advanced Hydraulic Punching

- What It Does: Includes pre-programmed hydraulic punching units to create holes or slots in the purlins as per design requirements.

- Why It’s Useful: Streamlines the manufacturing process, eliminating the need for secondary operations.

4. Precision Cutting System

- Technology Used: Servo-driven cutting ensures clean, burr-free cuts for professional finishes.

- Why It Matters: Enhances product quality and reduces material waste.

5. Material Versatility

- Compatible Materials:

- Galvanized steel

- Cold-rolled steel

- High-strength steel

- Thickness Range: 1.5mm–3.0mm

- Why It’s Important: Supports a wide range of applications, from light-duty to heavy-duty construction.

6. PLC-Controlled Automation

- Features:

- A user-friendly touchscreen interface for easy operation.

- Programmable settings to store multiple purlin profiles.

- Real-time performance monitoring and error detection.

- Why It’s Important: Ensures consistent quality and simplifies machine operation.

7. Compact and Modular Design

- What It Offers: Space-saving design that integrates seamlessly into existing production lines.

- Why It Matters: Optimizes factory floor space and allows for future upgrades.

8. Safety Features

- Highlights:

- Emergency stop buttons for immediate shutdown.

- Overload protection to prevent damage during operation.

- Protective covers for moving parts.

- Why It’s Important: Ensures operator safety and extends machine lifespan.

Production Workflow of a C Purlin Roll Forming Machine

Here’s how the machine transforms raw steel coils into high-quality C purlins in a fully automated process:

1. Decoiling

- Flat steel coils are loaded onto the decoiler, which feeds the material into the machine.

2. Leveling

- A leveling system ensures the material is flat and free from warping before entering the roll-forming section.

3. Punching

- Hydraulic punching units create slots, holes, or embossments as required by the design.

4. Roll Forming

- The material passes through a series of precision rollers, gradually shaping it into the desired C profile.

5. Cutting

- A servo-driven cutting system trims the purlins to the specified lengths with clean, burr-free edges.

6. Stacking

- Finished purlins are automatically stacked for easy packaging and transportation.

Pricing of High-Quality C Purlin Roll Forming Machines

The cost of a C Purlin Roll Forming Machine depends on its features, production capacity, and level of customization. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Basic Machines | Standard C purlin production | $60,000–$90,000 |

| High-Speed Machines | Enhanced speed and punching precision | $90,000–$130,000 |

| Fully Customizable Machines | Advanced features, multi-profile capability | $130,000–$180,000 |

For tailored pricing and financing options, contact Wuxi Sunway Machinery.

Advantages of Using C Purlin Roll Forming Machines

Investing in a C Purlin Roll Forming Machine offers numerous benefits for manufacturers:

1. Efficiency

- High-speed production and integrated punching reduce lead times and boost productivity.

2. Precision

- Advanced automation ensures consistent quality, minimizing defects and rework.

3. Versatility

- Supports a wide range of C purlin sizes, thicknesses, and applications.

4. Cost Savings

- Reduces labor costs, material waste, and operational downtime, improving profitability.

5. Scalability

- High production capacity allows manufacturers to scale operations as demand grows.

Troubleshooting Common Issues in C Purlin Roll Forming Machines

Even the most advanced machines may encounter occasional issues. Here’s how to resolve common problems:

1. Uneven Purlin Profiles

- Cause: Misaligned rollers or incorrect settings.

- Solution: Realign the rollers and verify forming parameters in the PLC system.

2. Material Jams

- Cause: Improper feeding or debris in the machine.

- Solution: Clean the rollers and ensure proper material alignment.

3. Cutting Inaccuracies

- Cause: Worn cutting blades or incorrect servo settings.

- Solution: Replace or sharpen the blades and adjust the servo motor parameters.

4. Punching Errors

- Cause: Misaligned punching dies or insufficient hydraulic pressure.

- Solution: Realign the dies and adjust punching parameters in the control system.

For persistent issues, contact the Wuxi Sunway Machinery technical team for expert assistance.

FAQs About C Purlin Roll Forming Machines

| Question | Answer |

|---|---|

| What is the production speed? | Most machines operate at speeds of 10–20 meters per minute, depending on material and design. |

| Can the machine produce different sizes? | Yes, fully adjustable settings allow for the production of various widths, heights, and thicknesses. |

| What materials are compatible? | Galvanized steel, cold-rolled steel, and high-strength steel. |

| Is operator training included? | Yes, comprehensive training is provided with every machine purchase. |

| What is the warranty period? | Sunway machines come with a 12-month warranty, with extended options available. |

| Can the machine integrate with other equipment? | Absolutely! Sunway machines are designed for seamless integration into automated production lines. |

Emerging Global Trends Shaping the Demand for C Purlin Roll Forming Machines

C purlins are at the heart of modern steel construction. As global construction evolves, several key trends are driving the demand for C Purlin Roll Forming Machines:

1. Growth of Green Building Initiatives

- The Context: Sustainable construction is no longer optional; it’s a mandate. Governments and industries worldwide are adopting green building standards.

- Impact on C Purlins: Made from recyclable steel, C purlins are a sustainable choice for building frameworks.

- Why It Matters: Roll-forming machines that minimize waste and produce high-quality, eco-friendly C purlins align perfectly with green building goals.

2. Rising Demand for Pre-Engineered Buildings (PEBs)

- The Trend: Pre-engineered buildings are becoming the preferred choice for industrial, commercial, and agricultural projects due to their cost and time efficiency.

- Impact on C Purlins: C purlins are a fundamental component of PEBs, providing structural support for roofs and walls.

- Machine Relevance: High-speed roll-forming machines ensure manufacturers can meet the increasing demand for PEB components.

3. Urbanization in Emerging Economies

- The Numbers: By 2030, over 60% of the world’s population will live in urban areas, driving the need for robust construction materials.

- Impact on C Purlins: Lightweight yet strong, C purlins are ideal for high-rise buildings and urban infrastructure.

- Why It Matters: Machines capable of producing a variety of C purlin sizes can cater to diverse urban construction projects.

4. Advancements in Modular Construction

- What’s Happening: Modular construction is transforming how buildings are designed and built, emphasizing off-site manufacturing for on-site assembly.

- Impact on C Purlins: Modular construction heavily relies on prefabricated components like C purlins.

- Machine Relevance: Roll-forming machines with precise, programmable settings are essential for producing modular-friendly components.

5. Increased Focus on Lightweight Construction

- The Shift: Lightweight materials like C purlins are gaining favor as they reduce overall building weight without compromising strength.

- Why It Matters: Manufacturers equipped with advanced roll-forming machines can capitalize on this trend by producing high-quality, lightweight purlins.

Automation Advancements in C Purlin Roll Forming Machines

Automation is revolutionizing the roll-forming industry, and C Purlin Roll Forming Machines are at the forefront of this technological shift. Here are the most significant innovations:

1. Real-Time IoT Integration

- What It Does: Connects the machine to the internet for real-time monitoring and diagnostics.

- Benefits:

- Predictive maintenance alerts reduce downtime.

- Operators can monitor production remotely.

- Analytics offer insights into machine performance for continuous improvement.

2. Fully Programmable PLC Control

- Features:

- Stores multiple purlin profiles and production parameters.

- Intuitive touchscreen interface for easy operation.

- Real-time error detection and troubleshooting.

- Why It’s Important: Enhances user control and ensures consistent production quality.

3. Quick Changeover Mechanisms

- What It Offers: Allows seamless switching between purlin sizes and profiles without significant downtime.

- Why It Matters: Increases production flexibility, especially for manufacturers handling custom orders.

4. Servo-Driven Cutting and Punching

- How It Works: High-speed servo motors control the cutting and punching systems for precision and burr-free results.

- Why It’s Important: Reduces material waste and enhances the quality of the final product.

5. Digital Twin Technology

- What It Is: A virtual replica of the roll-forming machine that simulates production runs.

- Why It’s Revolutionary:

- Eliminates trial-and-error on the actual machine, saving time and materials.

- Speeds up the development of custom purlin designs.

6. Machine Learning Algorithms

- How It Helps: Machine learning analyzes production data to recommend optimal settings for speed, pressure, and material type.

- Why It’s Valuable: Improves efficiency, reduces errors, and adapts to changing production requirements.

Environmental Impact of C Purlin Roll Forming Machines

Sustainability is a critical consideration for manufacturers and builders alike. Here’s how C Purlin Roll Forming Machines contribute to a greener future:

1. Minimal Material Waste

- How It Works: Precision forming and cutting systems optimize material usage, reducing scrap.

- Impact: Lowers production costs and minimizes environmental impact.

2. Energy Efficiency

- The Innovation: Modern machines feature energy-efficient servo motors and hydraulic systems.

- Why It Matters: Reduces electricity consumption, lowering both operational costs and carbon emissions.

3. Recyclable Products

- The Advantage: Steel C purlins are 100% recyclable, supporting circular economy principles.

- Outcome: Encourages sustainable construction practices.

4. Reduced Transportation Emissions

- How It Helps: Localized production of C purlins reduces the need for long-distance transportation.

- Impact: Lowers greenhouse gas emissions associated with logistics.

Comparison: C Purlin Roll Forming Machines vs. Traditional Manufacturing Methods

When considering the production of C purlins, it’s essential to evaluate the advantages of roll-forming machines over traditional methods:

| Feature | C Purlin Roll Forming Machine | Traditional Methods (e.g., Pressing and Welding) |

|---|---|---|

| Precision | High; ensures consistent profiles and dimensions | Moderate; prone to human and mechanical errors |

| Production Speed | Fast; 10–20 meters per minute | Slow; dependent on manual processes |

| Automation | Fully automated with PLC and IoT integration | Mostly manual or semi-automated |

| Material Waste | Minimal; optimized processes reduce scrap | Higher; inefficient processes lead to more waste |

| Customization | Easily customizable for various purlin sizes | Limited flexibility; requires separate tooling |

| Cost Efficiency | Higher initial cost, lower long-term costs | Lower initial cost, higher operational costs |

| Scalability | Ideal for high-volume production | Not suitable for large-scale manufacturing |

Additional FAQs About C Purlin Roll Forming Machines

| Question | Answer |

|---|---|

| What is the typical machine lifespan? | With proper maintenance, the machine can last over 15–20 years. |

| Can the machine handle custom profiles? | Yes, programmable settings allow for custom dimensions and designs. |

| Is operator training required? | Yes, but comprehensive training is provided with every machine purchase. |

| How often is maintenance needed? | Regular maintenance is recommended every 6–12 months, depending on usage. |

| What are the warranty terms? | Sunway machines come with a 12-month warranty and optional extended warranties. |

| Does Sunway provide spare parts? | Absolutely! Sunway ensures a steady supply of spare parts to keep your machine running. |

Why Wuxi Sunway Machinery is the Industry Leader

When it comes to C Purlin Roll Forming Machines, Wuxi Sunway Machinery has earned its reputation as an industry leader. Here’s why:

- Global Expertise: Decades of experience serving clients across Asia, Europe, Africa, and the Americas.

- Custom Solutions: Machines tailored to meet specific production needs and market requirements.

- Innovative Technology: From IoT integration to digital twin technology, Sunway leads the way in innovation.

- Sustainability Focus: Machines designed to minimize waste and energy consumption.

- Comprehensive Support: Installation, training, troubleshooting, and spare parts—Sunway has you covered.

- Proven Quality: Every machine complies with international quality standards, ensuring reliability and performance.

Conclusion: Revolutionizing Steel Construction

The High-Quality C Purlin Roll Forming Machine is more than just equipment—it’s a transformative tool that empowers manufacturers to meet the evolving demands of modern construction. With its efficiency, precision, and scalability, this machine is an investment in the future of your business.

Ready to elevate your production capabilities? Contact Wuxi Sunway Machinery today to explore their state-of-the-art roll-forming solutions. Together, let’s build the future of steel construction—one C purlin at a time!