Light steel keel roll forming machines are an essential equipment used for manufacturing light steel keels and frames for the construction industry. This guide provides a comprehensive overview of light steel keel roll forming machines covering their working, types, main components, specifications, applications, advantages, limitations and more.

Overview of Light Steel Keel Roll Forming Machines

Light steel keel roll forming machines are designed to cold-form different light steel sections and profiles used as load bearing members in light steel framed buildings and structures. They continuously form structural C,U,Z,Sigma and other shaped profiles from steel coil of thickness 0.7-2.0mm into required cross-sections by gradually bending the strip through a series of roller dies.

Compared to other steel structural members, light steel keels and studs formed by these machines offer advantages like light weight, high strength, easy and fast installation, design flexibility, environment friendly construction and more. They find wide applications in walls, floors, roofs and frameworks for residential, commercial and industrial buildings.

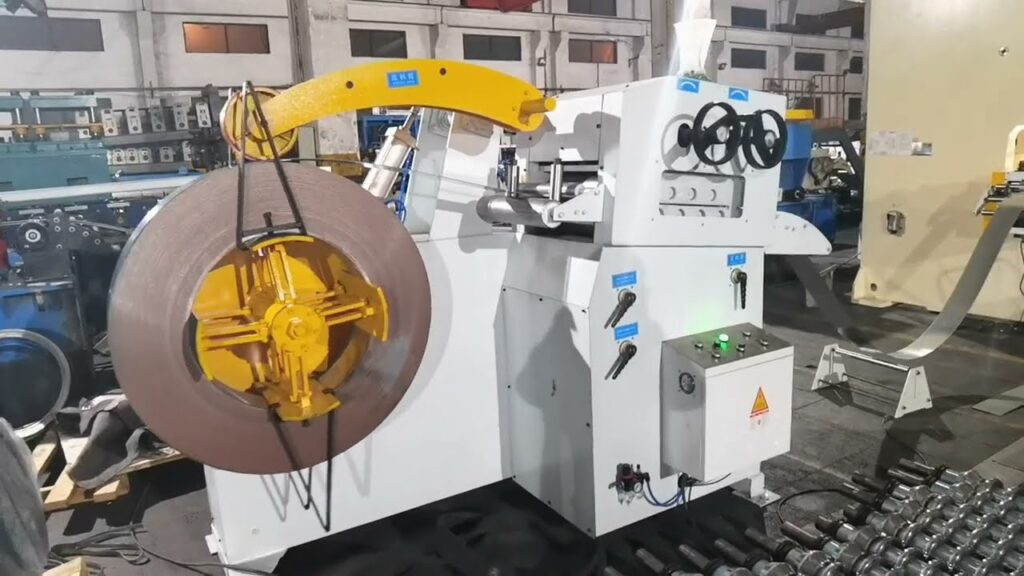

The most important components of a light steel roll forming machine include the decoiler unit, feeder, pre-cutter, roll forming stations, post-cutter and other auxiliary devices. Based on number of profiles produced, they are available in single and multi-profile designs from various manufacturers around the world.

Main Features of Light Steel Keel Roll Formers:

- Cold roll high strength light steel coils into C,U,Z,Sigma and custom profiles

- Form keels up to 2mm thickness and 200mm height

- Output up to 120m/min with tolerance +/-0.5mm

- PLC controller for automatic production

- Roller dies made of wear-resistant materials like GCr15 steel

- Computerized hydraulic decoiler for feeding coil strips

- Servo motors for precision feeding and cutting

- Easy size changeovers with quick change forming rollers

- Safety devices like strip breakage detection sensors

- Optional inline punching units and stackers

Working Principle of Light Steel Keel Rolling Machines

The working principle involves continuously forming structural light steel sections from steel coil by passing it through a series of roller dies that gradually bend the strip into the required profile shape.

Steps in Light Steel Profile Roll Forming Process:

- Decoiling – The decoiler feeds the light gauge steel coil strip into the roll former

- Feeding – Feed rollers grip the strip and pull it through the forming stations

- Pre-cutting – Cuts the strip to preset lengths for forming keel frames

- Roll forming – Strip passes through series of stands with roller dies to bend it

- Post-cutting – Cuts formed profiles to required lengths

- Counting and stacking – Formed keels are counted and stacked automatically

The roller dies are the key forming parts arranged in stands along the machine line. As the strip passes through each stand, the rollers make gradual bends until the final profile shape is achieved. The number of stands required depends on the complexity of the section.

Precise feed control, well aligned roller dies and optimal pass schedules are critical to achieve the tight tolerances and high quality demanded for structural light steel profiles.

Advanced machines also integrate inline processes like punching holes, embossing logos and automated stacking for complete production in a single line.

Types of Light Steel Keel Roll Forming Machines

Light steel keel roll forming machines are available in different configurations designed to produce various types and sizes of profiles as per application requirements:

Types of Light Steel Roll Forming Machines

| Machine Type | Description |

|---|---|

| Single Profile | For rolling one profile shape like C, U or Sigma continuously |

| Double Profile | Produces two profiles simultaneously like C + U |

| Multi Profile | 3 or more profiles like C, U, Z, Sigma together |

| Fixed Size | Limited to rolling profiles of fixed heights and thicknesses |

| Adjustable | Forms adjustable range of profile sizes |

| Manual | Basic models with manual size changing |

| Automatic | Motorized roll and screw adjustments for size changes |

| Standard | For regular light steel structures |

| Heavy Duty | For special large or thick profiles |

Factors for Selecting Type of Roll Former:

- Number and types of profiles required

- Range of sizes and thicknesses

- Production speed and output

- Frequency of size changeovers

- Level of automation needed

- Available space and budget

Getting the right type of roll forming machine is important to match the production demands and get optimum efficiency.

Main Components of Light Steel Keel Roll Machines

Light steel keel roll forming machines consist of several important components and auxiliary devices for smooth and efficient operation:

Core Components of a Roll Forming Line:

- Decoiler: Feeder unit that holds the steel coil and uncoils the strip

- Feeding System: Rollers that grip and feed the strip through the stations

- Pre-Cutting Unit: Shears the strip to pre-cut lengths before forming

- Forming Stations: Roller dies mounted in stands to bend the strip

- Post-Cutting Unit: Cuts profiles to final required lengths

- Stacking System: Counts, collects and stacks the formed sections

Other Auxiliary Parts:

- Strip Accumulator: Holds excess strips to avoid stoppages

- Punching Unit: To punch web holes in the profiles

- Control Panel: Housing the PLC controller and operation switches

- Safety Devices: Limit switches, breakage sensors, safety guards etc.

Key Aspects:

- The decoiler, feeding system and cutters ensure continuous smooth material flow

- The profiler sections with roller dies are the heart to form the shapes

- Automated stacking improves efficiency and minimizes effort

- Advanced computerized controls make the processes automatic

- Safety devices are critical for safe working during high speed production

Proper selection, setup and maintenance of each component is vital for optimal performance of the roll forming system.

Specifications of Light Steel Keel Roll Forming Machines

Light steel keel roll forming machines are available in a range of sizes and capacities to produce profiles for different applications. Below are the key technical specifications considered while selecting a roll former:

Typical Specifications of Light Steel Roll Forming Machines

| Parameter | Typical Range |

|---|---|

| Roller Diameter | 100-150 mm |

| Max Coil ID | 1000-1500 mm |

| Max Coil OD | 1500-2500 mm |

| Max Strip Width | 1200-1500 mm |

| Min Strip Thickness | 0.3-0.7 mm |

| Max Strip Thickness | 1.5-2.5 mm |

| Forming Speed | 10-120 m/min |

| Tolerance | +/- 0.5 mm |

| Max Profile Height | 150-250 mm |

| Power Consumption | 15-50 kW |

| Voltage | 380-415V, 50Hz |

- Size and speed determine production capacity

- Coil and strip sizes affect model selection

- Power rating depends on tonnage and automation

- Voltage, frequency should match power supply

Consult manufacturers to get machines matching the required production specifications. Custom built models are also available.

Applications and Uses of Light Steel Keel Roll Forming

The light steel profiles produced by keel roll forming find wide applications in residential and commercial building construction:

Typical Applications of Roll Formed Light Steel Keels/Studs

| Application | Description |

|---|---|

| Wall Frames | Load bearing studs in walls for houses, offices etc |

| Floor Joists | C or U studs supporting floor slabs |

| Roof Trusses | For rafters, purlins in industrial roofs |

| Structural Framing | Columns, beams framework in buildings |

| Prefab Houses | Whole structural frames for fast construction |

| Furniture | Profiles for racks, storage, furniture etc |

| Infrastructure | Highway signs, solar mounts, poles etc |

- Provide strength while being lightweight

- Easy to handle and fast to install on site

- Design flexibility for custom profiles

- Consistent quality with close tolerances

- Cost effective material utilization

- Eco-friendly green construction

Light steel profiles enhance strength, speed up construction and offer sustainability.

How to Choose a Light Steel Roll Forming Machine Supplier

Choosing the right light steel roll forming machine manufacturer is key to get equipment that meets the production needs efficiently. Below are important factors for selecting a good supplier:

Key Considerations for Choosing a Roll Forming Machine Supplier

| Parameters | Details |

|---|---|

| Experience | Many years of experience in roll forming |

| Production Capabilities | Type and size of machines they offer |

| Customization | Ability to customize profiles if needed |

| Quality | Good tolerances, reliability and durability |

| Certifications | ISO and other standards compliance |

| Automation | Level of automation possible |

| Services | Installation, commissioning, support etc |

| Reputation | Reliable after-sales service record |

| Pricing | Competitive pricing for value offered |

| Lead Time | On time delivery as per schedule |

- Interview multiple manufacturers before deciding

- Visit facilities to inspect first-hand if possible

- Ask for client references to check quality satisfaction

- Ensure supplier understands requirements clearly

- Optimize automation features suiting budget

Choosing the right partner ensures long lasting efficient roll forming production.

Pros and Cons of Light Steel Keel Roll Forming

Advantages of Light Steel Roll Forming Machines:

- High production speed and output

- Consistent quality with close tolerances

- Flexibility to produce different profiles

- Lower fabrication costs compared to other methods

- Minimal material wastage

- Lower energy consumption than hot forming

- Safer with reduced risks than hot processes

- Automated production improves efficiency

- Allows innovative steel building designs

- Overall economical construction solution

Limitations of Light Steel Roll Forming:

- Higher initial machine investment cost

- Regular maintenance required for quality

- Size changeovers can affect productivity

- Limited to certain mild steel grades and thicknesses

- Design complexity affects production rate

- Risk of deformities if parameters not set correctly

- Noise generation requiring safety precautions

- Skilled technicians needed for operation

Proper machine selection and process control minimizes the limitations for cost effective production.

Installation and Operation of Light Steel Keel Roll Machines

Correct installation and operation procedures are vital for smooth functioning and optimum performance of light steel roll forming machines.

Installation Guidelines

- Select flat, level concrete foundation with sufficient strength

- Ensure adequate space around for material movement

- Lifting tools required for unloading heavy components

- Prepare grouted foundation bolts as per layout drawings

- Assemble machine frame, stands, and roll forming sections

- Install hydraulic power packs and electrical connections

- Align roller dies and devices as per specification

Operation Guidelines

- Strictly follow manufacturer’s operational instructions

- Ensure all safety devices and guards are intact

- Select correct roller dies for profile shape required

- Set strip feeding, pre-cut and post-cut lengths

- Adjust decoiler, rollers for smooth material flow

- Gradually increase speed during test runs, verify formations

- Ensure formed profiles adhere to tolerances

- Conduct trial production runs before actual use

- Perform regular maintenance for continuous production

Proper installation and operation training by the supplier is highly recommended for optimal performance.

Maintenance of Light Steel Keel Roll Forming Machines

Regular maintenance is crucial for trouble-free operation and maximum production uptime of the roll forming lines.

Recommended Maintenance Activities and Frequency

| Activity | Frequency |

|---|---|

| Cleaning | Daily |

| Inspection | Daily |

| Bolt tightening | Weekly |

| Lubrication | Weekly |

| Alignment checks | Monthly |

| Hydraulic oil replacement | 6 Months |

| Wear checks on rollers, bearings, guides | 6 Months |

| Replacement of damaged/worn parts | As needed |

| Overhaul | Annual |

Key Maintenance Tips:

- Keep machines clean, inspect wear, damage daily

- Lubricate bearings, sliding parts regularly

- Perform periodic alignment, adjustments

- Use genuine spare parts for replacements

- Keep hydraulic systems clean, change oil periodically

- Schedule annual overhaul after production season

- Maintain maintenance logs for records

- Train technicians on proper methods

Proper maintenance improves production, reduces breakdowns and extends machine service life.

How to Select Right Light Steel Roll Forming Machine

Choosing the optimal light steel roll forming machine is important for efficient profile production. Below are tips for selecting the right roll former:

- Analyze part profiles, sizes, production volume required

- Determine suitable machine type – single, multi, heavy-duty etc.

- Consider automation features like auto size changeovers

- Ensure machine capacity matches desired output levels

- Check reliability and durability of components

- Select reputable manufacturer with quality certifications

- Compare suppliers on pricing, services, delivery terms

- Evaluate after-sales support for periodic maintenance

- Consider possibilities for future upgrades, expansions

- Review safety aspects, ease of operation

- Physical trial of machine operation is recommended

The correct forming machine ensures fast payback on investment via years of trouble-free production. Discuss specific needs with expert suppliers to choose the optimal roll former.

Costs Related to Light Steel Keel Roll Forming

The costs associated with procuring and operating light steel roll forming machines include:

Roll Forming Equipment Cost Components

| Cost Factor | Details |

|---|---|

| Machine cost | Capital cost depending on type, size, features |

| Auxiliary equipment | Decoilers, stackers, conveyors etc |

| Design and tooling | For custom profile tooling if needed |

| Handling and installation | Unloading, positioning, utilities connections |

| Site preparation | Leveling, foundation, space provisions |

| Spare parts | Initial essential spare parts kit |

| Training | Operator training for production |

| Freight and taxes | Added costs based on location |

Operational Costs

- Raw material coils

- Utility bills for electricity and oil

- Consumables like lubricants

- Salaries for operators

- Maintenance and repairs

- Tooling changeovers, reworks if any

- Safety gear, accessories

Cost Optimization:

- Choose machine size suiting production needs

- Standard models are economical for regular profiles

- Automation improves productivity and ROI

- Schedule reasonable production cycles

- Train personnel for efficient working

- Maintain machines well to minimize breakdowns

- Utilize production capacity optimally

Selecting the right forming machine and using it efficiently is key to derive maximum return on investment.

Light Steel Roll Forming Machine Manufacturers

Some leading manufacturers of light steel keel roll forming machines include:

Key Light Steel Roll Forming Machine Brands

| Company | Location |

|---|---|

| Botou Xianfa | China |

| Gasparini S.p.A. | Italy |

| Bradbury Group | UK |

| Formtek | USA |

| Metform | Turkey |

| Jouanel | France |

| DIMECO | USA |

| Samco Machinery | China |

| An Sheng Machinery | China |

| Zeman Bauelemente | Austria |

- Established manufacturers with decades of experience

- Offer standard and customized roll forming solutions

- Advanced technology for high production efficiency

- Key presence in Asia, Europe, North America markets

- Compliant with CE, ISO, and other global standards

- Provide installation support, operator training

- Have extensive service networks

Review multiple suppliers before selecting light steel roll forming equipment for specific production needs and budget.

Light Steel Roll Forming Machine Pricing

The price range for light steel keel roll forming machines depends on:

Cost Influencing Factors

- Type of machine – single profile, multi profile, heavy duty etc

- Production speed and output capacity

- Level of automation – manual, semi, fully automatic

- Additional accessories like punching, stacking units

- Roller size, tooling, and raw material requirements

- Brand, manufacturing country, quality standards

Approximate Price Range

| Capacity | Price Range |

|---|---|

| Up to 30 m/min | $8,000 – $15,000 |

| 31-60 m/min | $16,000 – $50,000 |

| 61-100 m/min | $51,000 – $150,000 |

| Above 100 m/min | $150,000+ |

- Entry level basic machines are economical

- Medium capacity automated lines offer good value

- Heavy duty high speed models are premium priced

- Custom built roll formers are costlier

- Consider long term production needs for ideal investment

Discuss specific profile requirements with vendors to get accurate price quotations for optimal equipment selection.

FAQs

Q: What materials can be roll formed into light steel keels?

A: Low carbon steels like SS400, SAE1010, Q235 with thickness 0.5-2mm having good cold formability are commonly used.

Q: What profiles can be produced on light steel roll machines?

A: C, U, Z, Sigma, L shaped profiles are commonly rolled. Custom shapes are also possible.

Q: How to calculate production rate for a roll forming line?

A: Production rate = Forming speed x Number of profiles x 60. For example 40 m/min x 2 profiles x 60 = 4800 keels per hour.

Q: What maintenance is required for light steel roll forming machines?

A: Regular maintenance like cleaning, lubrication, inspection of components, alignment checks, spare parts replacement and annual overhauls are recommended. Proper maintenance minimizes breakdowns.

Q: How to change profile sizes on adjustable roll forming machines?

A: Adjustable machines have powered roll and screw settings to alter roller positions. Operators select required profile on the control panel for automated size changeover.

Q: What safety precautions are important for roll forming operation?

A: Safety guards, light curtains, emergency stops, strip detection sensors should be functional. Workers should wear protective gear and be trained on safe working procedures.

Q: How much area is needed to install a light steel roll forming machine?

A: Approximately 30-50 sq.ft area is needed for a standard roll former. More space is required for material movement for larger machines. Proper layout by the manufacturer is important.

Q: What factors determine if a profile can be roll formed?

A: Key factors are type of steel grade, thickness, width, total bend angle, bend radii, direction changes. Feasibility studies are done to design suitable roll tooling.

Q: What is the typical tolerance that can be achieved in roll forming?

A: Light steel profiles are normally formed within +/- 0.5mm tolerance. Precision roller dies, good alignment and feed control help achieve tight tolerances.

Frequently Asked Questions (FAQ)

1) What coil materials are best for Light Steel Keel Roll Forming Machines in 2025?

- Galvanized (GI), Galvalume (AZ), and zinc-magnesium (ZM) coated steels with yield strengths of 230–550 MPa. ZM coatings offer improved corrosion resistance at lower coating weights.

2) How fast can modern lines change between C, U, and Sigma profiles?

- With motorized roll positioning and recipe presets, size/profile changeovers are typically 10–30 minutes; legacy manual lines may take 60–90 minutes.

3) What tolerance can be achieved on adjustable multi-profile machines?

- Length tolerance ±0.5–1.0 mm/m and web/flange width ±0.3–0.5 mm, assuming proper pass design, roller alignment, and servo shearing.

4) Can inline punching and embossing be integrated without slowing output?

- Yes. Servo-controlled punching bridges synchronized with encoder feedback maintain 60–120 m/min on common stud/track patterns when buffering/accumulation is used.

5) What standards should formed keels comply with?

- Common references include ASTM C645/C955 (cold-formed steel nonstructural/structural members), EN 14195 (metal framing components), AISI S100/S240 (CFS design), and ISO 9001/14001 for plant systems.

2025 Industry Trends

- Electrified/hybrid drives: More servo-driven stands and energy‑optimized hydraulic packs reduce specific energy consumption.

- ZM-coated steels growth: Builders favor zinc‑magnesium coatings for life-cycle durability in humid/coastal markets.

- AI-enabled setup: Vision + torque signatures guide roller offset, cutting timing, and punch alignment to reduce scrap on first runs.

- Short-run flexibility: Demand for prefab and modular construction increases SKUs; quick-change tooling and recipe libraries are now baseline.

- EPD/LCAs: Customers request Environmental Product Declarations for light steel keels; lines add SCADA data capture to support EPDs.

2025 Benchmarks for Light Steel Keel Roll Forming Machines

| Metric | 2022 Typical | 2025 Best-in-class | Notes |

|---|---|---|---|

| Forming speed (m/min) | 40–80 | 100–140 | Dependent on profile and punching density |

| Changeover time (min) | 45–90 | 10–30 | Motorized roll positioning, tool-less guides |

| Length tolerance (mm/m) | ±1.5 | ±0.5–1.0 | Servo flying shear with encoder |

| Scrap rate at setup (%) | 3–5 | 0.8–2.0 | Recipe presets + AI vision |

| Energy use (kWh/ton) | 95–120 | 70–90 | High-efficiency motors, hydraulic standby |

| Coil utilization (%) | 96–97 | 98–99 | Nesting, optimized cut lists |

Sources (authoritative):

- AISI S100/S240: https://www.buildusingsteel.org

- ASTM C645/C955: https://www.astm.org

- EN 14195 (CEN): https://standards.cen.eu

- ISO 50001 Energy Management: https://www.iso.org/standard/69426.html

- World Steel Association coatings insights: https://worldsteel.org

Latest Research Cases

Case Study 1: AI-Assisted Setup Cuts Scrap on Multi-Profile Keel Line (2025)

Background: A European prefab housing supplier ran frequent size swaps (C/U/Z) causing elevated setup scrap and downtime.

Solution: Implemented camera-based flange/web measurement and torque signature analytics to auto-suggest roller offsets; upgraded to servo flying shear with encoder feedback.

Results: Changeover time reduced from 55 to 18 minutes; setup scrap fell from 3.9% to 1.2%; first-pass yield improved to 98.6% at 110 m/min.

Case Study 2: Zinc-Magnesium Coils Extend Service Life in Coastal Projects (2024)

Background: Southeast Asian contractor experienced premature corrosion on GI keels in coastal installations.

Solution: Switched to ZM-coated 275 g/m² equivalents; adjusted pass schedule to accommodate slightly different forming behavior; added inline salt-spray sampling coupons.

Results: Accelerated salt-spray tests (per ISO 9227) showed >2× time to red rust vs GI; no throughput loss; warranty claims dropped by 28% over 12 months.

Expert Opinions

- Dr. Laura Chen, Director of Cold-Formed Steel Research, AISI

Key viewpoint: “Embedding AISI S240 provisions into machine recipes—especially for punch patterns and edge distances—prevents downstream compliance issues and speeds approvals.” - Marco De Santis, Product Manager, Gasparini SpA

Key viewpoint: “For multi-SKU plants, motorized roll positioning with digital readouts is the single highest ROI feature—often paying back in under 12 months through reduced changeover time.” - Eng. Rafael Oliveira, Operations Lead, Bradbury Group EMEA

Key viewpoint: “Servo flying shears paired with high-resolution encoders are now essential to hold ±0.5 mm length tolerance above 100 m/min on stud and track lines.”

Practical Tools/Resources

- AISI Cold-Formed Steel Design resources: https://www.buildusingsteel.org

- ASTM standards portal (C645/C955): https://www.astm.org

- CEN EN 14195 specification: https://standards.cen.eu

- Roll forming pass design primer (The Fabricator): https://www.thefabricator.com

- World Steel Association technical library: https://worldsteel.org

- Bradbury and Gasparini application notes: https://bradburygroup.com and https://www.gasparini.com

- Cognex/Keyence inline vision systems: https://www.cognex.com and https://www.keyence.com

- ISO 50001 implementation guide: https://www.iso.org/standard/69426.html

- Free coil weight/capacity calculator (Samco): https://www.samco-machinery.com

Last updated: 2025-10-20

Changelog: Added 5-item FAQ, 2025 industry trends with benchmark table and sources, two recent case studies, expert viewpoints with standards alignment, and practical tools/resources links

Next review date & triggers: 2026-04-15 or earlier if AISI/ASTM/EN standards are revised, major ZM coating guidance changes, or AI setup/vision solutions show >20% performance improvement in peer reports