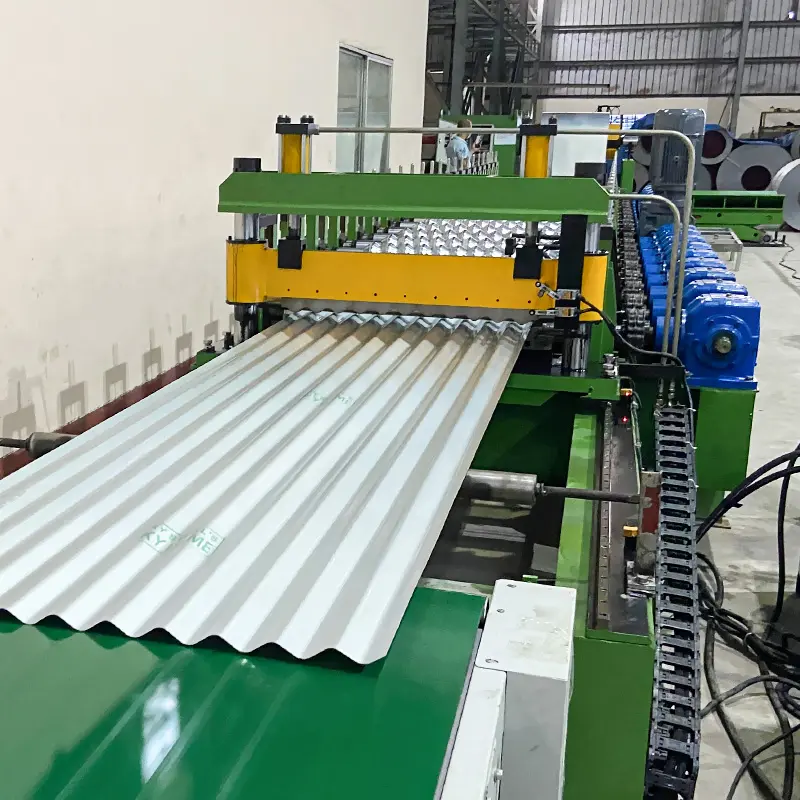

The roll forming process has been an essential component of the manufacturing industry for decades, allowing for the production of high-quality and consistent profiles at scale. Among the various types of roll forming machines, the width corrugated sheet roll forming machine stands out for its ability to produce large, durable panels with intricate shapes and designs. As technology continues to evolve, the future of width corrugated sheet roll forming machines is ripe with potential for innovation and growth. In this post, we’ll explore the current state of technology, emerging trends, potential applications, challenges, and opportunities associated with the future of width corrugated sheet roll forming machine technology.

Current State of Technology for width corrugated sheet roll forming machine

The current state of technology for width corrugated sheet roll forming machines is highly advanced, allowing for the production of a wide range of materials and profiles with varying levels of automation and customization.

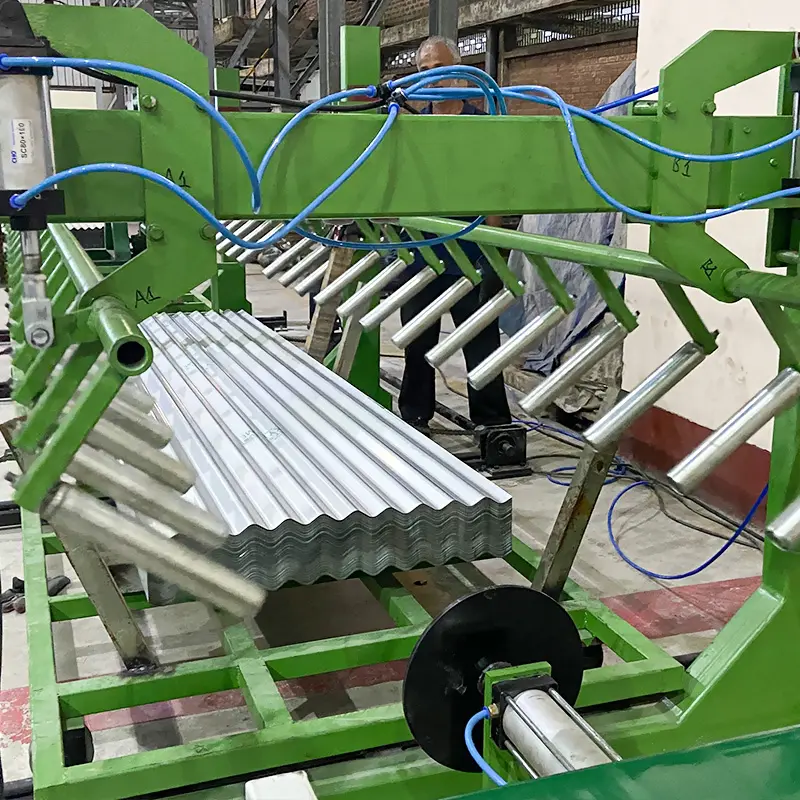

Materials commonly used in width corrugated sheet roll forming machines include steel, aluminum, copper, and other metals, as well as composite and plastic materials. These materials can be formed into a variety of profiles, including traditional corrugated sheets, sinusoidal profiles, trapezoidal profiles, and more complex shapes and designs.

Automation has also played a significant role in the current state of technology for width corrugated sheet roll forming machines. Many machines now feature advanced computerized controls that allow for precise control of the forming process, resulting in greater consistency and quality in the final product. Automation also allows for faster production times, reduced labor costs, and increased efficiency.

Customization is also becoming more common in width corrugated sheet roll forming machines. Advances in technology have made it possible to create unique shapes and designs, as well as to customize profiles to meet specific customer requirements.

In summary, the current state of technology for width corrugated sheet roll forming machines is highly advanced, offering a wide range of materials and profiles, as well as advanced automation and customization capabilities. As technology continues to evolve, we can expect to see even greater innovation and growth in this field.

Emerging Technologie of width corrugated sheet roll forming machines

As technology continues to evolve, several emerging technologies are likely to impact the future of width corrugated sheet roll forming machines. These technologies include:

- Materials Science: Advances in materials science are likely to enable the development of new materials with improved properties, such as greater strength, durability, and corrosion resistance. This could open up new possibilities for the production of wider and more complex corrugated sheet profiles.

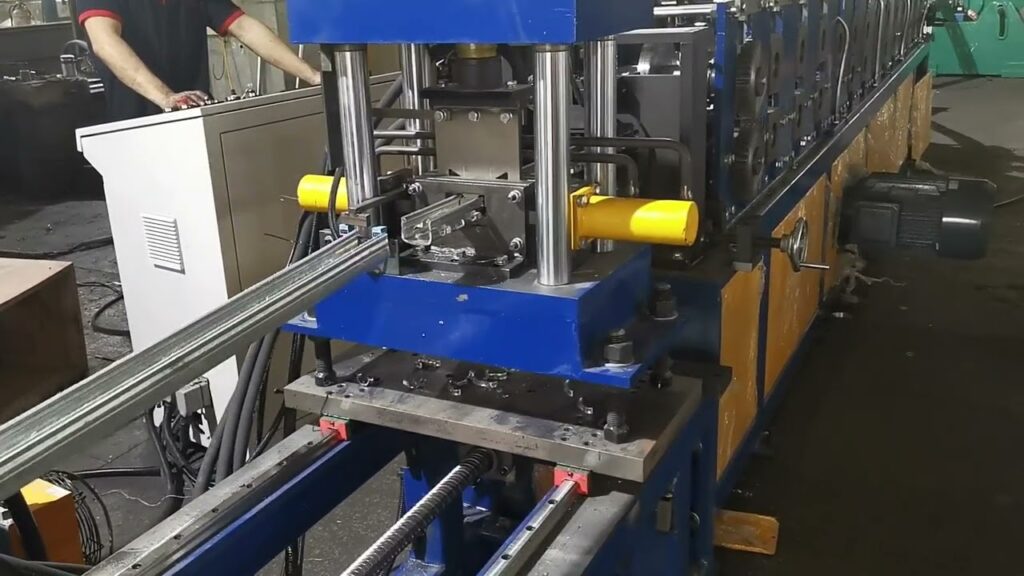

- Robotics and Automation: The integration of robotics and automation is likely to increase the efficiency and precision of width corrugated sheet roll forming machines. Robots can perform repetitive tasks with greater accuracy, while advanced automation systems can improve the speed and quality of the production process.

- 3D Printing: 3D printing is an emerging technology that has the potential to revolutionize the production of complex and customized corrugated sheet profiles. This technology allows for the creation of intricate shapes and designs that would be difficult or impossible to produce using traditional roll forming methods.

- Artificial Intelligence: The integration of artificial intelligence into width corrugated sheet roll forming machines can help to optimize the production process, minimize waste, and improve the quality of the final product. AI can also help to identify potential defects and make real-time adjustments to the production process to ensure consistent quality.

In summary, emerging technologies such as advanced materials science, robotics, 3D printing, and artificial intelligence are likely to have a significant impact on the future of width corrugated sheet roll forming machines. By embracing these technologies, manufacturers can improve the efficiency, quality, and versatility of their production processes.

Industry Trends of width corrugated sheet roll forming machine

-

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Cable Ladder Roll Forming Machine

Cable Ladder Roll Forming Machine -

PV Mounting Bracket C Shape Profile Roll Forming Machine

PV Mounting Bracket C Shape Profile Roll Forming Machine -

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine -

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile)

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile) -

PV Mounting Bracket Z Shape Profile Roll Forming Machine

PV Mounting Bracket Z Shape Profile Roll Forming Machine -

Solar mounting strut channel roll forming machine

Solar mounting strut channel roll forming machine -

Strut Channel Roll Forming Machine

Strut Channel Roll Forming Machine

Several industry trends are driving the development of width corrugated sheet roll forming machine technology. These trends include:

- Sustainable Materials: There is a growing demand for sustainable materials in the manufacturing industry, and width corrugated sheet roll forming machines are no exception. Manufacturers are looking for ways to produce corrugated sheets that are made from recycled materials or materials that are renewable and eco-friendly.

- Energy-Efficient Manufacturing Processes: Another trend driving the development of width corrugated sheet roll forming machine technology is the need for energy-efficient manufacturing processes. Manufacturers are seeking ways to reduce energy consumption and minimize waste in their production processes, which can improve efficiency and reduce costs.

- Customization and Flexibility: There is an increasing demand for customization and flexibility in the production of corrugated sheet profiles. Manufacturers are seeking ways to produce unique shapes and designs, as well as to customize profiles to meet specific customer requirements. This requires the use of advanced technologies that allow for greater flexibility and customization in the production process.

- Digitization and Industry 4.0: The digitization of manufacturing processes and the emergence of Industry 4.0 are also driving the development of width corrugated sheet roll forming machine technology. The use of sensors, real-time data analysis, and artificial intelligence can improve the efficiency and quality of the production process, as well as provide valuable insights into machine performance and maintenance needs.

In summary, the demand for sustainable materials, energy-efficient manufacturing processes, customization and flexibility, and digitization and Industry 4.0 are driving the development of width corrugated sheet roll forming machine technology. Manufacturers that embrace these trends and invest in advanced technologies are likely to be more competitive and better positioned to meet the evolving needs of their customers.

Challenges and Opportunities of width corrugated sheet roll forming machine

The future of width corrugated sheet roll forming machine technology presents both challenges and opportunities for manufacturers in the industry. Here are some key points to consider:

Challenges:

- Increased Competition: As technology advances, the competition in the industry is likely to increase. Manufacturers will need to invest in advanced technologies to stay competitive and keep up with changing customer demands.

- Need for Skilled Labor: The adoption of advanced technologies in width corrugated sheet roll forming machines will require skilled labor to operate and maintain the machines. Finding and retaining skilled workers may be a challenge for some manufacturers.

- Cost of Investment: Advanced technologies can be expensive to acquire and implement, and may require significant investment in research and development. This can be a challenge for smaller manufacturers with limited budgets.

Opportunities:

- Increased Efficiency: The adoption of advanced technologies in width corrugated sheet roll forming machines can improve efficiency and productivity in the manufacturing process, resulting in cost savings and increased profitability.

- Customization and Flexibility: Advanced technologies can enable greater customization and flexibility in the production process, allowing manufacturers to meet specific customer requirements and stay competitive in the industry.

- New Markets and Applications: The adoption of advanced technologies in width corrugated sheet roll forming machines can open up new markets and applications, such as in the aerospace, automotive, and construction industries.

- Sustainability: The use of sustainable materials and energy-efficient manufacturing processes can provide opportunities for manufacturers to differentiate themselves from competitors and meet the growing demand for sustainable products.

In summary, while the future of width corrugated sheet roll forming machine technology presents challenges such as increased competition, the need for skilled labor, and cost of investment, it also presents opportunities such as increased efficiency and productivity, customization and flexibility, and new markets and applications. By embracing these opportunities and investing in advanced technologies, manufacturers can position themselves for success in the evolving manufacturing industry.

The future of width corrugated sheet roll forming machines is poised for significant advancements with the integration of emerging technologies. The use of sustainable materials, robotics and automation, 3D printing, and artificial intelligence will enable manufacturers to achieve greater efficiency, customization, and quality in production. The industry is also driven by the need for energy-efficient manufacturing and greater flexibility in customization. However, manufacturers must overcome the challenges of increased competition, the need for skilled labor, and high investment costs. Despite the challenges, the future presents a plethora of opportunities for manufacturers to grow and innovate.