Cold roll forming machine price can vary significantly depending on a number of factors, such as the size and make of the machine, its features, and additional costs like rolling mill. However, the cost of the machines is not always reflective of its quality. Check out this article for more information about what you need to know when buying your cold roll forming machine!

What is a cold roll forming machine?

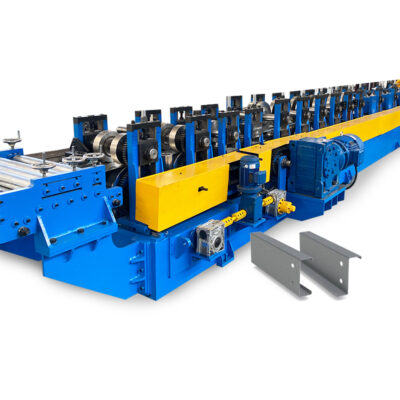

A cold roll forming machine is a specialized equipment that helps to produce metal sheet products, like cold rolls. It uses pressure and heat to deform metal into desired shapes. Cold roll forming machines are typically used in the automotive and industrial industries, as they are able to create products with tighter tolerances and more precise dimensions than manual methods.

There are a few things you need to know before buying a cold roll forming machine. The first is the size of the product you want to form. The machine will require a certain space in order to function properly, so make sure your budget allows for this. Second is the speed of the machine; this will determine how quickly you can produce products. Finally, be aware of the type of material you want to use; some machines only work with certain types of metals.

the cold roll forming machine price

A cold roll forming machine is a versatile industrial machine that can be used to produce a variety of shapes and sizes of rolls. It usually has multiple stations that allow the user to customize the size, shape, and thickness of the finished product.

Cold roll forming machine price will vary depending on its features and specifications. Generally speaking, most machines cost between $10,000 and $30,000. However, you will need to factor in the cost of the dies and other equipment needed to operate the machine, as well as maintenance costs. And the cold roll forming machine price also depends on the manufacturer, so it is important to do your research before making a purchase.

Types of Roll Forming Machines

There are several types of roll forming machines, each with its own set of benefits and drawbacks. This guide will discuss the different types and give a brief overview of their features.

Cylindrical Rolling Machine (CRM)

The cylindrical rolling machine is perhaps the most common type of roll forming machine. It uses a pair of cylinders to shape the metal sheet into a desired shape. CRMs are typically fast and efficient, but they can be difficult to use because they require some degree of manual dexterity.

Rotary Hammer Type Roll Forming Machine

The rotary hammer type roll forming machine is similar to the cylindrical rolling machine, but it uses a hammer instead of a pair of cylinders to create the metal sheet. Rotary hammers are faster than cylindrical hammers, but they tend to produce more noise and dust. They also require less manual dexterity than CRMs, making them easier to use for people who aren’t comfortable with hands-on work.

Twin-Stage Hammer Type Roll Forming Machine

The twin-stage hammer type roll forming machine is similar to the rotary hammer type roll form machine, but it has two hammers that work together to create the metal sheet. Twin-stage hammers are slower than rotary hammers, but they produce less noise and dust. They also require less manual dexterity than CRMs, making them easier to use for people who aren’t comfortable with hands-on work.

Wire EDM Machine

The wire EDM machine is a type of roll forming machine that uses electric current to shape the metal sheet. Wire EDMs are fast and efficient, but they can be difficult to operate because they require a high degree of manual dexterity. They are also limited in the size and shape of the metal sheets they can form.

-

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Cable Ladder Roll Forming Machine

Cable Ladder Roll Forming Machine -

PV Mounting Bracket C Shape Profile Roll Forming Machine

PV Mounting Bracket C Shape Profile Roll Forming Machine -

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine -

Light Keel Wall Angle Roll Forming Machine Protector Corners Wall Angle Forming Machine

Light Keel Wall Angle Roll Forming Machine Protector Corners Wall Angle Forming Machine -

Light Keel Corner Bead Making Machine V Keel Angle Iron Roll Forming Machine

Light Keel Corner Bead Making Machine V Keel Angle Iron Roll Forming Machine -

Full Automatic C Z Purlin Machine Steel Metal Former Frame & Purlin Machines

Full Automatic C Z Purlin Machine Steel Metal Former Frame & Purlin Machines -

Fully Automatic Hydraulic Easy Operation 80-300 Adjustable C Purlin Making Machine Roll Forming Machinery

Fully Automatic Hydraulic Easy Operation 80-300 Adjustable C Purlin Making Machine Roll Forming Machinery

Advantages of the Cold Roll Forming Machines

There are many advantages of using cold roll forming machines. They are simple to operate and can be customized to produce a variety of products. Some of the main benefits include:

-They are fast and efficient, making them ideal for high volume production

-They are versatile, able to produce a wide range of products

-They are reliable, providing consistent results regardless of the product being produced

-They are affordable, making them an attractive option for small businesses and home entrepreneurs

Disadvantages of the Cold Roll Forming Machines

There are a few disadvantages of the cold roll forming machines. The most important downside is that they are very slow and can only form thin sheets. Another disadvantage is that the sheets can be prone to tearing and fraying.

Conclusion

If you’re in the market for a cold roll forming machine, it’s important to understand what you need to know in order to make an informed purchase. In this article, we will outline the different types of cold roll forming machines available on the market and cold roll forming machine price. Armed with this information, you should be able to make an informed decision as to which model is right for your needs.