Steel roll forming machines are used for a variety of purposes, but they can be put to use in any type of industry. The process is used for making different types of pipes and pipe fittings, machine parts and general metal work. While these are all beneficial uses, using steel roll forming machines has other benefits as well. In this article we will take a look at the many benefits that roll formers offer.

What is a Steel Roll Forming Machine?

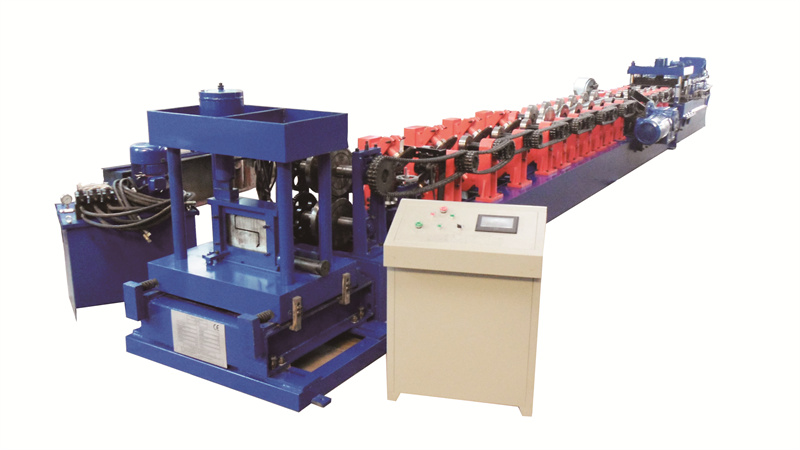

A steel roll forming machine is a type of construction equipment that is used to create various types of shapes and components from steel sheets. The machine uses a series of rollers to bend and shape the steel into the desired form. These machines are typically used in industrial settings, but they can also be used for smaller projects such as creating custom parts for cars or other objects.

5 Reasons Why Steel Roll Forming Machines Are Beneficial

Roll forming machines offer many benefits over other types of machines used to create steel products. Here are some reasons why roll forming machines are beneficial:

- Speed and Efficiency

Roll forming machines can produce steel products faster and more efficiently than other types of machines. This is because the rollers on the machine can quickly and easily form the steel into the desired shape. - Cost-Effective

Roll forming machines are cost-effective because they require less energy to operate than other types of machines. Additionally, they often last longer than other types of machines, which means you’ll save money in the long run. - Versatile

Roll forming machines are versatile and can be used to create a variety of different steel products. Whether you need to create beams, tubing, or sheet metal, a roll forming machine can do it all. - Easy to Use

Roll forming machines are easy to use, even for those with no prior experience. The machine does most of the work for you, so all you need to do is load the steel and choose your settings. - Durable

Roll forming machines are built to last. They’re made with high-quality materials that can withstand years of use. This means you won’t have to replace your roll forming machine anytime soon.

Applications of Steel Roll Forming Machines

Steel roll forming machines are commonly used to create metal sheets and coils that are used in a variety of applications. Some of the most common uses for steel roll formed products include:

• Roofing panels

• Siding panels

• Structural framing members

• Electrical conduit

• HVAC ductwork

• Automotive body panels

There are many reasons why steel roll forming machines are beneficial. Perhaps the most obvious reason is that they allow for a very high degree of accuracy when it comes to manufacturing steel products. Steel roll forming machines can produce products that are much more accurate than those produced by traditional methods. This is due to the fact that steel roll forming machines use a series of dies to shape the steel into its desired form.

Another reason why steel roll forming machines are beneficial is that they tend to be very fast. This means that manufacturers can produce a large number of products in a relatively short period of time. This is obviously a major advantage when it comes to meeting customer demand or increasing production levels.

Finally, it is worth mentioning that steel roll forming machines are generally very versatile. This means that they can be used to produce a wide range of different products. In fact, some manufacturers use them to produce products that would otherwise be impossible to create using traditional methods.

-

Semi Auto Size Changeable CZ Purlin Roll Forming Machine

Semi Auto Size Changeable CZ Purlin Roll Forming Machine -

Laser Welding Square Pipe Roll Forming Machine

Laser Welding Square Pipe Roll Forming Machine -

Vineyard Post Roll Forming Machine

Vineyard Post Roll Forming Machine -

Scaffolding Plank Roll Forming Machine

Scaffolding Plank Roll Forming Machine -

Light Gauge Steel Roll Forming Machine

Light Gauge Steel Roll Forming Machine -

Auto Size Changeable Sigma Purlin Roll Forming Machine

Auto Size Changeable Sigma Purlin Roll Forming Machine -

Auto Size Changeable C Z Purlin Roll Forming Machine

Auto Size Changeable C Z Purlin Roll Forming Machine -

Auto Size Changeable Z Purlin Roll Forming Machine

Auto Size Changeable Z Purlin Roll Forming Machine -

Auto Size Changeable C U Purlin Roll Forming Machine

Auto Size Changeable C U Purlin Roll Forming Machine

What is the Cost of a Steel Roll Forming Machine?

A steel roll forming machine is an apparatus that is used to form or shape different types of metals. The most common metals that are worked with these machines are aluminum and steel. There are many benefits to using a steel roll forming machine over other methods, but one of the most important is the cost.

The cost of a steel roll forming machine will vary depending on the size and complexity of the machine. However, in general, these machines are much less expensive than other methods of shaping metal. For example, a press brake can cost upwards of $100,000, while a comparable steel roll forming machine will only cost a few thousand dollars. This makes steel roll forming machines a much more affordable option for businesses that need to shape metal on a regular basis.

Conclusion

There are many reasons why steel roll forming machines are beneficial. They provide a high level of precision, they’re faster than traditional methods, and they’re more versatile. In addition, steel roll forming machines are less likely to damage the material being formed, and they produce less waste. If you’re looking for a way to improve your manufacturing process, investing in a steel roll forming machine is a great option.

FAQ

What is the use of forming machine?

During the forming process, the forming machine supplies work to the workpiece in the form of energy. This energy is used to overcome the deformation resistance of the material and to initiate and maintain the formation of the workpiece.