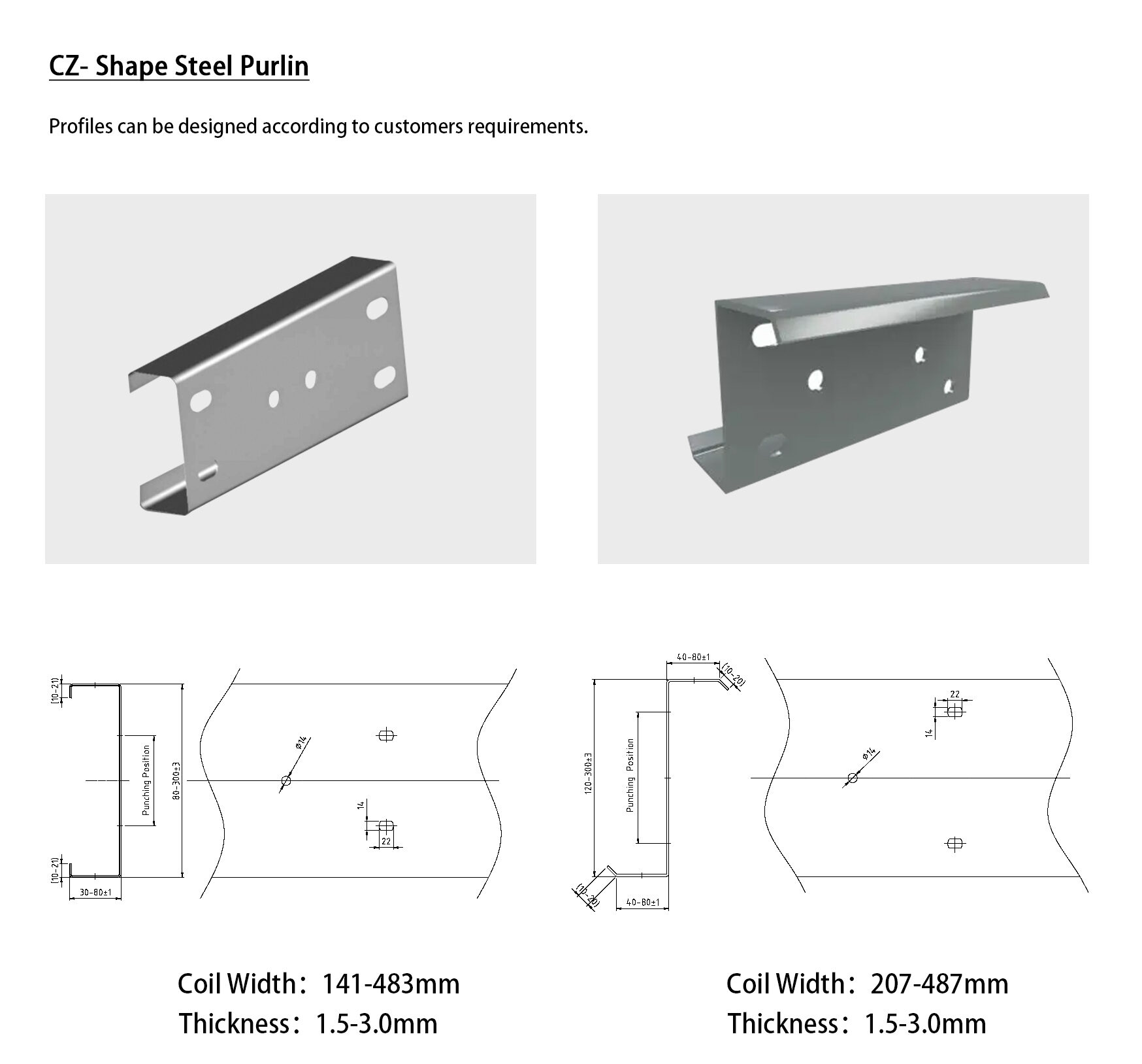

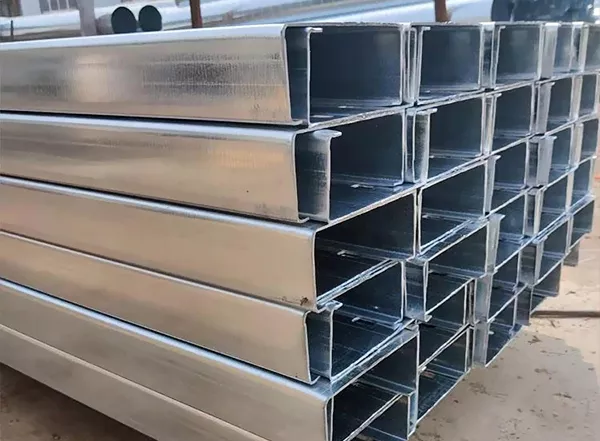

This Auto Size Changeable C Z Purlin Roll Forming Machine is used to produce C&Z shape purlins from 100-300mm of width, normally its material thickness is 1.5-3mm, also Maximum thickness can be formed at 4.0-6.0mm according to customer requirement.

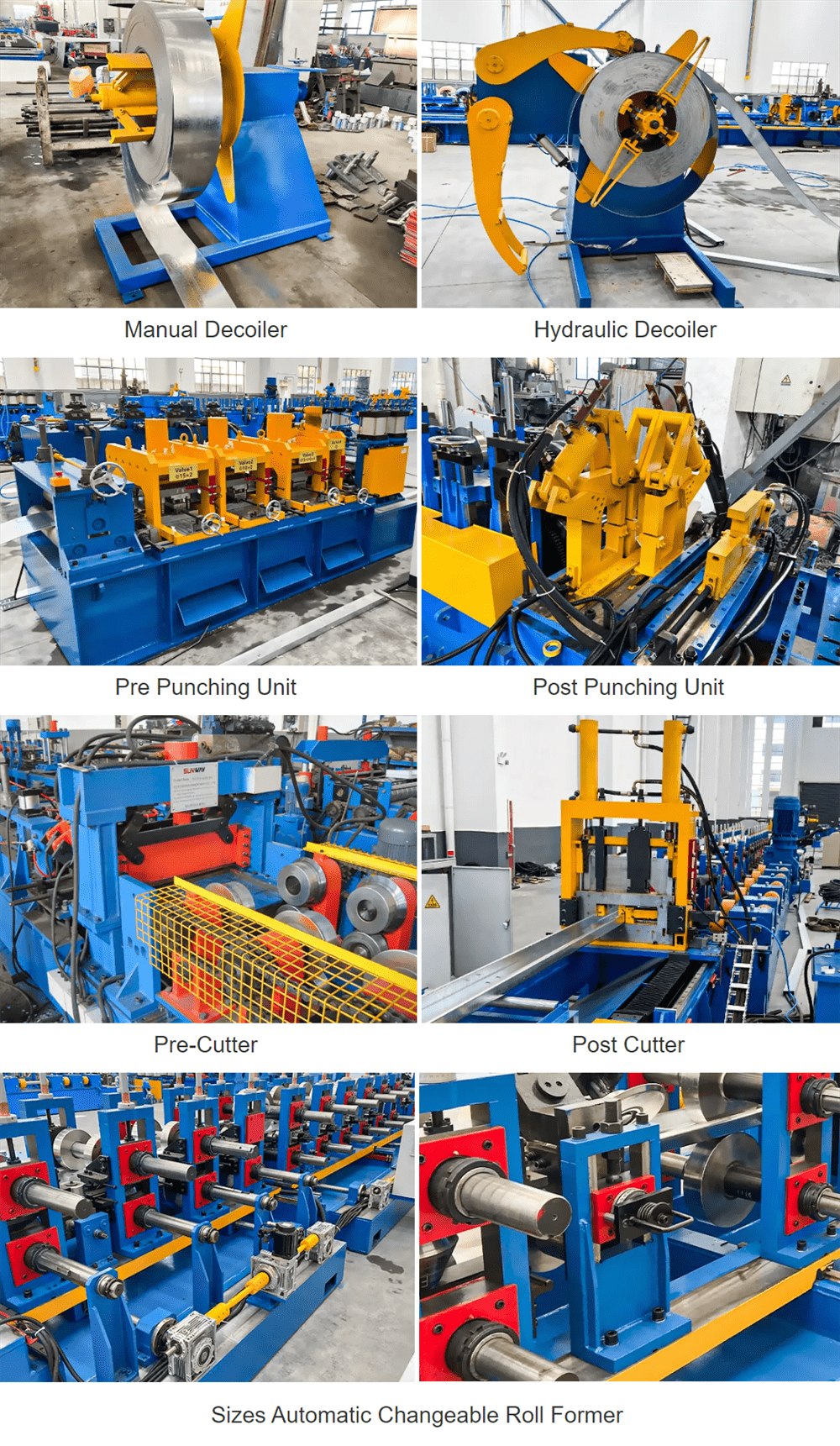

SUNWAY design this auto size changeable C Z purlin roll forming machine to work with any size of the purlin, automatically adjustable sizes by PLC. Whats’ more, Changing time from C to Z only need 10 minutes. Regarding the punching unit, we can design pre punching, post punching according to your requirement. For cutting unit, you can choose the pre-cut or post-cut which is universal cutting. The driving system we adopt the chain and mostly with gimbal /gearbox for transmission if the raw material is thicker than 2.5mm,this is much more strong driving power and more stable when forming the purlins.

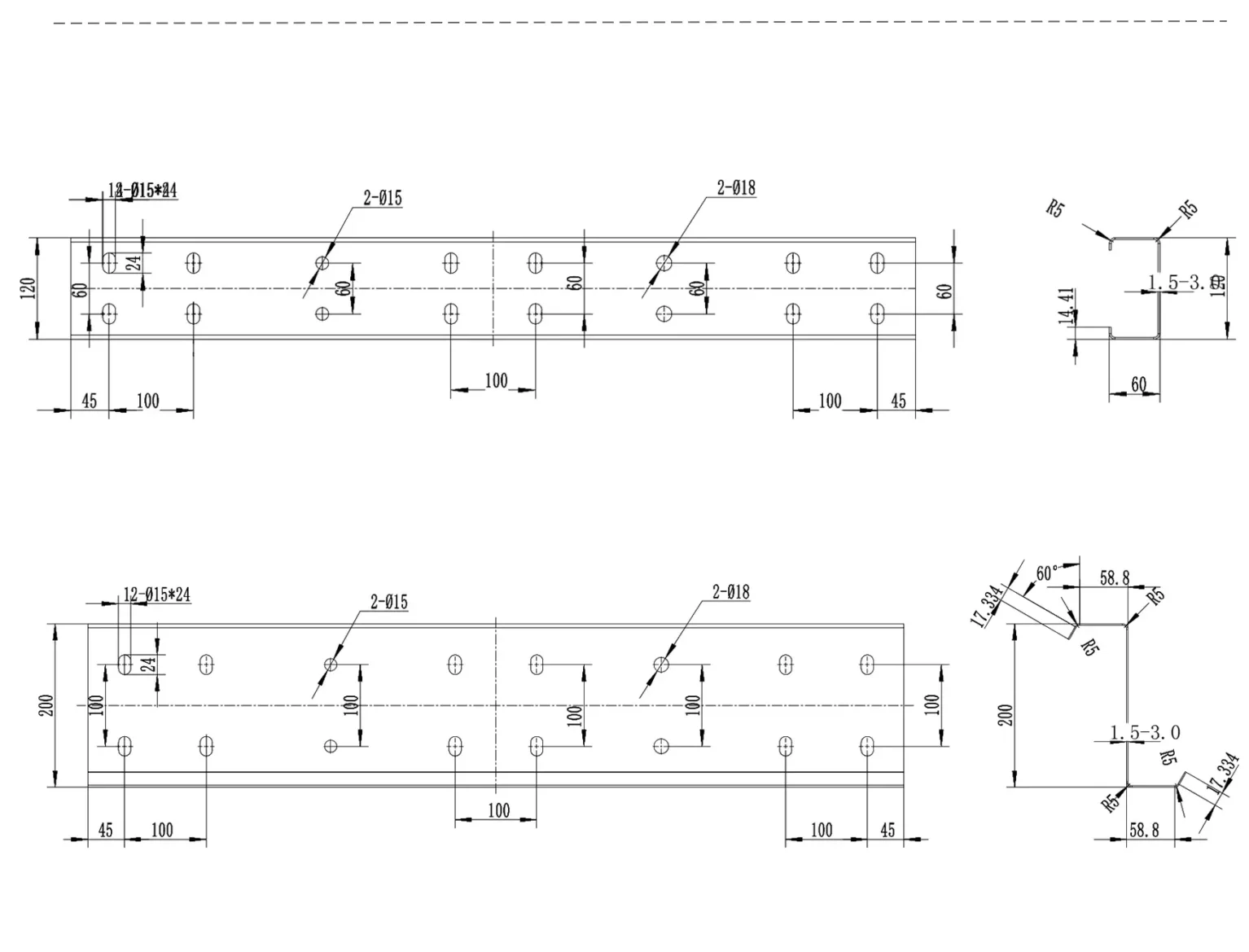

Purlin roll forming machine is the most popular and has an extensive use in Metal Building Systems, Huge RoofingSolutions, Construction and Renovation Projects etc. Our Purlin roll forming machine could produce C purlin, U purlin, Z purlin, machineable size range as follow: Width:100-300mm, Height: 50-100mm, Thickness:1.5-3mm. According to your section profile, size range, thickness range we could provide you different solutions of purlin roll forming machine to manufacturer a complete range of structual purlins (height and width change using automatic system by motors): If you only need to produce few sizes, we also suggest manually change sleeves, it’s more affordable.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

Click here to learn more about the purlin roll forming machine

Profile Drawings

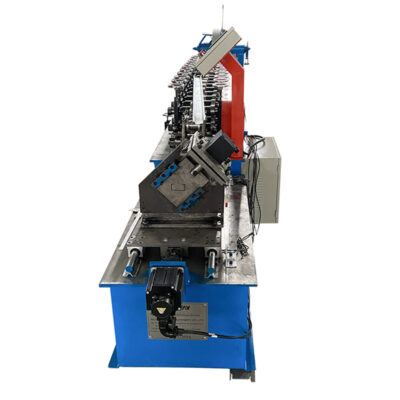

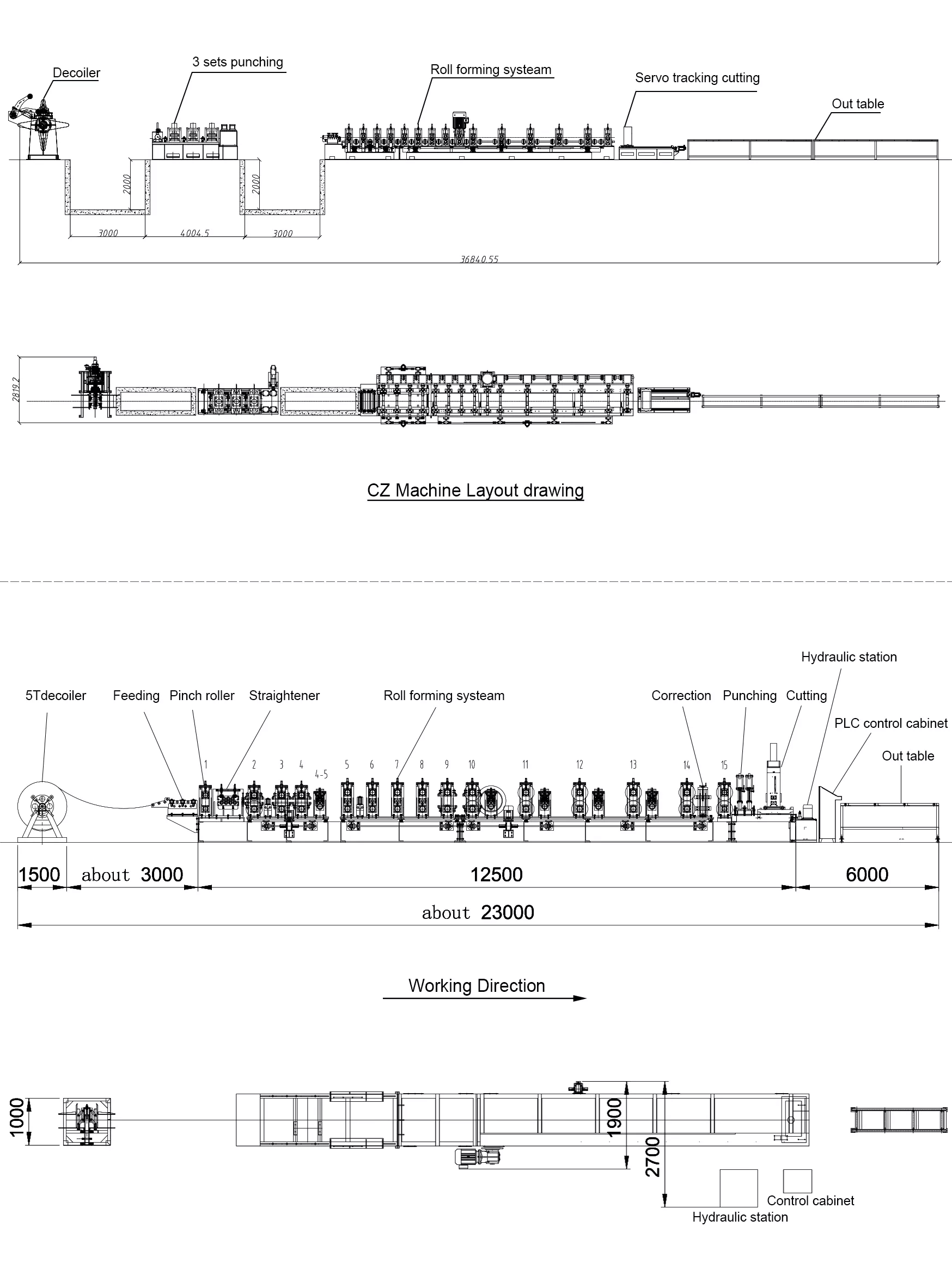

C Z Purlin Roll Forming Machine Production Line

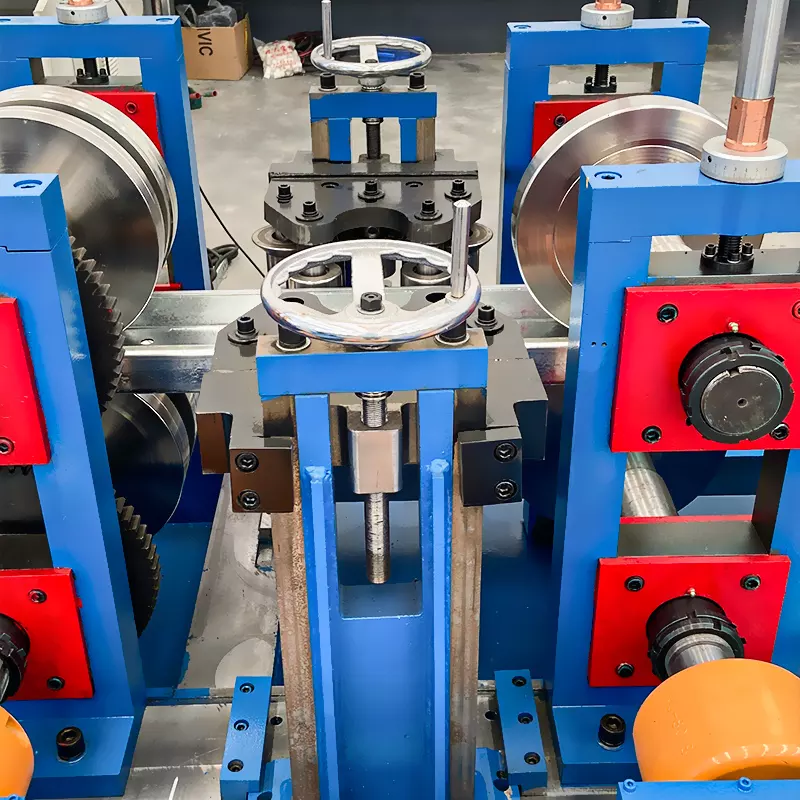

Product Details

C Z Purlin Roll Forming Machine Parameters

| Auto Size Changeable C/Z Purlin Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Coil |

Thickness(MM): 1.5-3 or as per customer

|

| B) Carbon Steel Coil | ||

| Yield Strength | 250 – 550 Mpa | |

| Tensil Stress | G350 Mpa-G550 Mpa | |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Punching System | Hydraulic Punching Station | * Pre-punch / Post Punch (Optional) |

| Forming Station | 16-18 Stations | |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Wall Panel Station | * Forged Iron Station (Optional) |

| Forming Speed | 10-20 (M/MIN) | * Or According To Your Requirement |

| Rollers’ Material | GCr 15 | * Cr12Mov (Optional) |

| Cutting System | Pre-cutting | * Post- universal Cutting (Optional) |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| PLC Brand | Panasonic | * Siemens (Optional) |

| Power Supply | 380V 50Hz | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

Application

what is c purlin roll forming machine?

A C purlin roll forming machine is an industrial machine used to produce C-shaped purlins, which are structural elements used in construction. The machine shapes flat metal coils into the C profile using rollers and tooling. It includes components like decoilers, leveling units, punching units, and cutting units. The machine operates automatically, ensuring high precision. C purlins are used to support roofs, walls, and other building structures.

The C purlin roll forming machine typically includes components such as decoilers to hold and feed the coil, leveling units to straighten the strip, punching units for creating holes or slots if required, and cutting units to cut the purlins to the desired length. The machine operates automatically, driven by motors and controlled by a computerized system, ensuring high precision and efficiency in the production process.

what is z purlin roll forming machine?

A Z purlin roll forming machine is an industrial machine used to produce Z-shaped purlins, which are structural elements used in construction. The machine shapes flat metal coils into the Z profile using rollers and tooling. It includes components for feeding, shaping, punching, and cutting the purlins. The machine operates automatically and is driven by motors. Z purlins are used for supporting roofs, walls, and other building components.

Similar to the C purlin roll forming machine, the Z purlin roll forming machine often includes components such as decoilers, leveling units, punching units, and cutting units. These components work together to feed the coil, straighten the strip, create holes or slots if required, and cut the purlins to the desired length.

what about oem purlin roll forming machine?

OEM purlin roll forming machine refers to a purlin roll forming machine that is manufactured by an Original Equipment Manufacturer (OEM). OEMs are companies that design, manufacture, and supply machinery or equipment to be used by other companies in their own products or processes.

The OEM purlin roll forming machine typically includes the necessary components and features for shaping flat metal coils into purlins of various profiles, such as C purlins, Z purlins, or other custom designs. It may have different configurations, such as varying numbers of roll sets, punching capabilities, cutting units, and automation features, depending on the specific needs of the customer.

The advantage of using an OEM purlin roll forming machine is that it is tailored to the customer’s requirements and integrates seamlessly into their production processes. OEM manufacturers have expertise in designing and producing roll forming machines, ensuring high quality, precision, and reliability in the equipment they supply.