The EPS sandwich panel roll forming machine is a machine used to form rolls of foam or polystyrene. It’s most often used on the edges of walls, ceilings, roofs, and floors to create a smooth surface without any visible joints. Check out this article to learn about what an EPS sandwich panel roll forming machine is and what it does.

Definition of EPS Sandwich Panel Roll Forming Machine

EPS sandwich panel roll forming machine is a kind of advanced equipment used in the production of electric vehicles and high-quality frameworks. It adopts the perfect folding method to produce EPS sandwich panels with good adhesion, no distortion, and no warping.

EPS sandwich panel roll forming machine is a specialized machinery for manufacturing EPS foam panels. The machine can produce three-dimensional EPS foam panels with high quality and uniform thickness. It has advantages such as fast production, low cost, and easy operation.

What Are the Benefits of an EPS Sandwich Panel Roll Forming Machine?

The EPS sandwich panel roll forming machine is a great option for manufacturing large sheets of panels. The machine has a wide range of features that make it an optimal choice for producing high-quality panels. Here are some of the benefits you can expect from using this machine:

• It is easy to operate.

• It is versatile and can be used to produce different types of panels.

• It is able to form large sheets of panels quickly and efficiently.

• It produces high-quality panels that are durable and resistant to wear and tear.

How Does an EPS Sandwich Panel Roll Forming Machine Work?

An EPS sandwich panel roll forming machine is a type of industrial robot that uses an overhead travelling beam to form large panels from sheets of extruded polystyrene (EPS) plastic. The robot has a movable work platform that supports the beam and a pair of rotating arms that hold the panels in place as they are formed.

The robot first cuts the panels into desired shapes using a cutting blade and then feeds them into the machine. The arm on the right side moves forward while the arm on the left side moves backward, pressing each panel against the adjacent panel until they form a single, continuous piece. The moving arms also create pressure along the length of each panel, which helps to reduce distortion and ensure that the finished product is accurately shaped.

EPS sandwich panel roll forming machines are commonly used in industries such as packaging, automobile manufacturing, and furniture manufacturing. They are generally very fast and efficient machines and can produce large quantities of finished products quickly and easily.

-

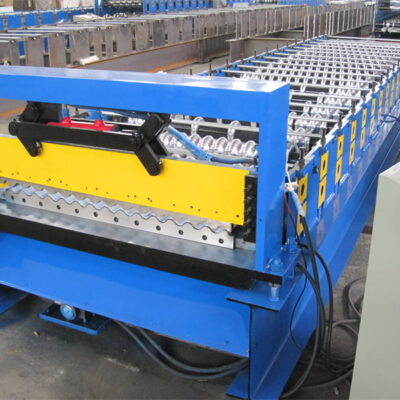

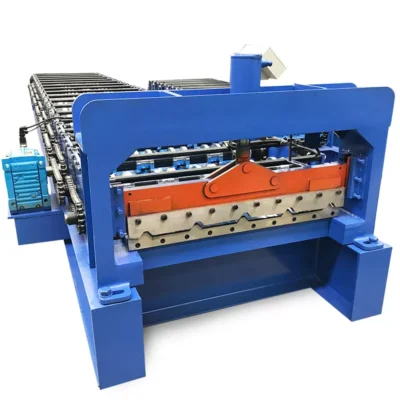

Trapezoidal Panel Roll Forming Machine

Trapezoidal Panel Roll Forming Machine -

Roof Tile Panel Roll Forming Machine

Roof Tile Panel Roll Forming Machine -

Trapezoidal panel roll forming machine

Trapezoidal panel roll forming machine -

Standing Seam Roof Panel Forming Machine

Standing Seam Roof Panel Forming Machine -

Roof Panel Double Layer Machine丨Tile &

Roof Panel Double Layer Machine丨Tile & -

Roof Tile Roll Forming Machine

Roof Tile Roll Forming Machine -

Bemo Roof Panel Roll Forming Machine

Bemo Roof Panel Roll Forming Machine -

Roof Tile Forming Machine Glazed Tile Making Machine Steel Sheet Roll Former

Roof Tile Forming Machine Glazed Tile Making Machine Steel Sheet Roll Former

Features of a Sandwich Panel Roll Forming Machine

A sandwich panel roll forming machine is a specialized piece of equipment used to form custom sandwich panels. This type of machine consists of a pair of rollers that are mounted on a movable platform, which can be positioned in front of or behind the workpiece. The rollers are then activated and move towards the workpiece, forcing it between the rollers. This process creates a sandwich panel that is precisely fit for your specific needs.

One of the key benefits of using a sandwich panel roll forming machine is the precision it allows you to achieve. Due to its design, this type of machine is able to create evenly shaped panels that are extremely durable. Additionally, since these machines are quick and easy to use, you can easily produce large quantities of customized panels quickly and without much hassle.

Overall, sandwich panel roll forming machines are an excellent option for those looking for high-quality custom sandwich panels. Their precise design and ease of use make them ideal for both small and large scale projects alike.

Why use a Sandwich Panel Forming Machine?

There are many benefits to using a sandwich panel forming machine. These machines can quickly and easily form panels that are precise in size and shape. They are also very economical to operate, making them the perfect choice for businesses that need to produce large numbers of customized panels quickly and affordably. Plus, they offer a high degree of versatility, allowing them to be used for a variety of other tasks, such as fabricating boxes or components out of aluminum or steel. Finally, sandwich panel forming machines are extremely reliable and can withstand a lot of wear and tear.

Conclusion

An EPS sandwich panel roll forming machine is a powerful tool that can be used in the manufacturing of various products. This type of machine is capable of rolling metal sheets into rolls or shapes, with the ability to produce high volumes in a short amount of time. This machine can be used to form a variety of products, including food packaging, automobile parts and other industrial goods. Before purchasing an eps sandwich panel roll forming machine, please read this article carefully, I believe you will know more about this product.

FAQ

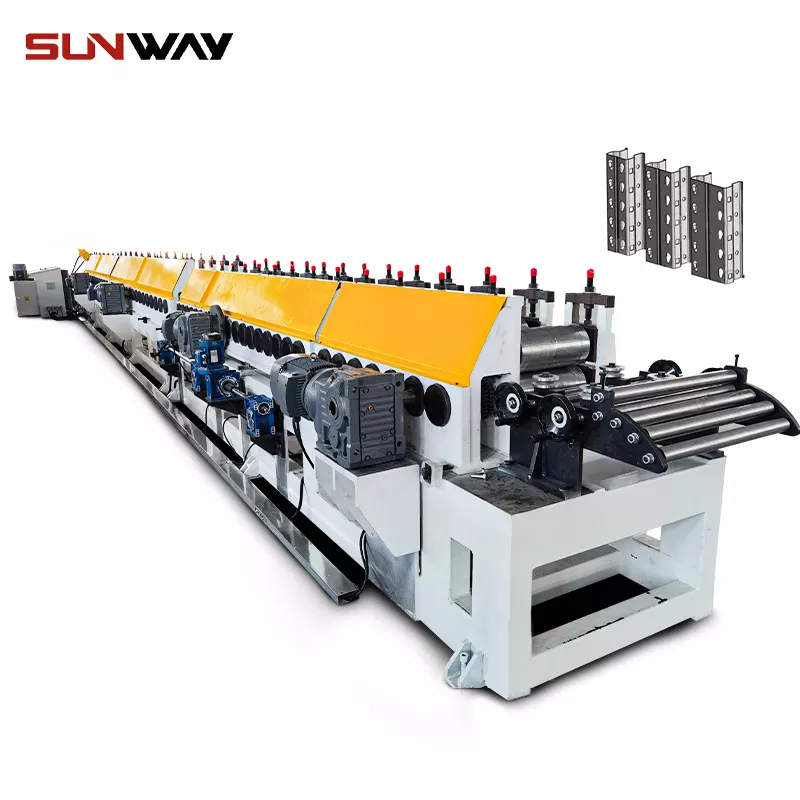

What is roll forming process?

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.