Roof tile panel roll forming machine is mainly used to produce roof tile panels. Normally the panel thickness is 0.3-0.8mm with normal galvanized steel or colored coil.

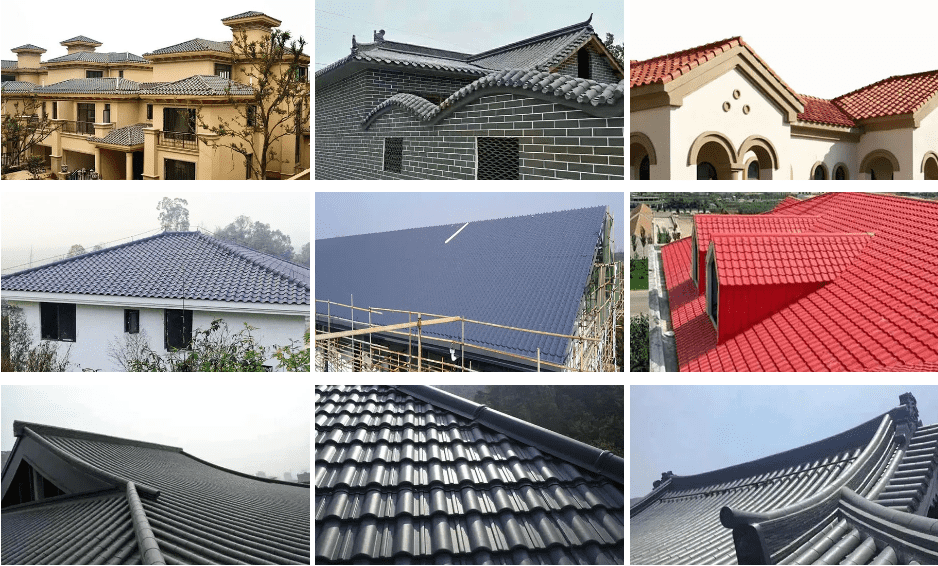

Roofing system roll forming machine has a big range of metal sheet profiles. It includes trapezoidal panel, corrugated panel, roof tile, glazed tile, metal deck, wall panel, standing seam, K span and ridge cap. Its products are widely used in roof and wall system in workshop construction and housing construction.

In Construction Industries, we are able to manufacture more machines like main channel roll forming machine, purlin roll forming machine, drywall roll forming machine, stud roll forming machine, track roll forming machine, top hat roll forming machine, clip roll forming machine, metal deck (floor deck) roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine, corrugated roll forming machine, ridge cap roll forming machine, downspout roll forming machine, etc.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

Profile Drawings

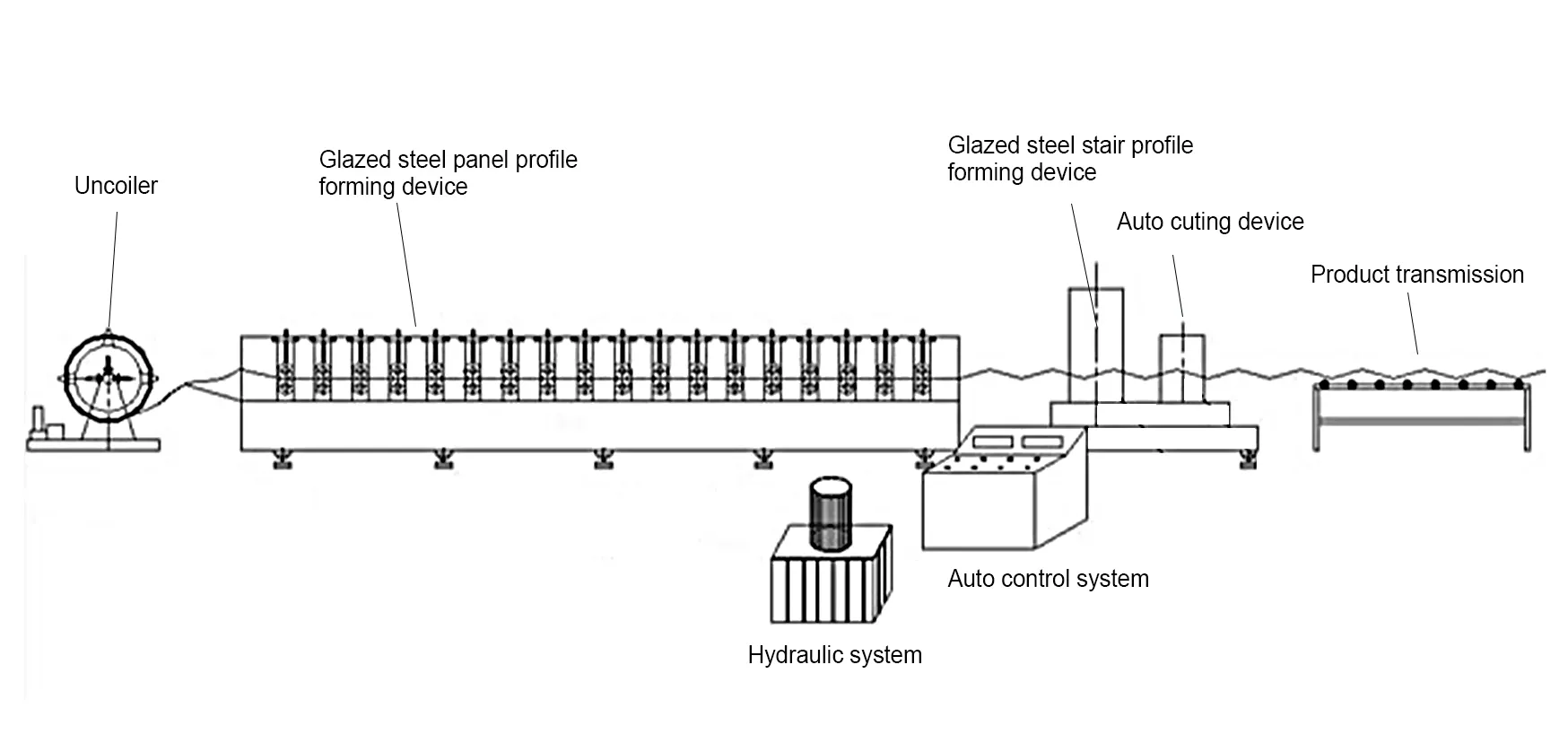

Production Line

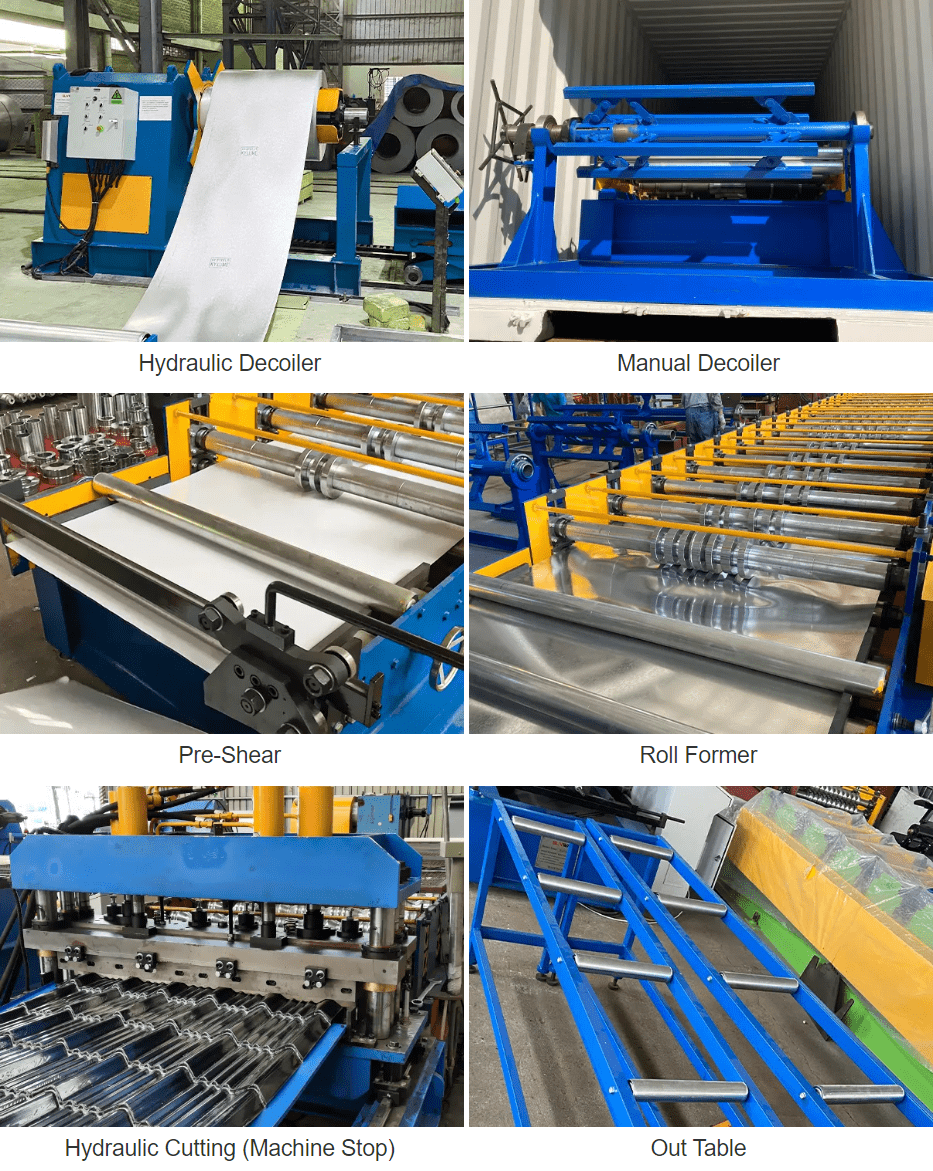

Product Details

Product Parameters

| Roof Tile Panel Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Coil |

Thickness(MM): 0.3-0.8 According To Your Requirement

|

| B) PPGI, PPGL | ||

| Yield Strength | 250 – 350 Mpa / 350-550Mpa | |

| Tensil Stress | 350 Mpa-550 Mpa | |

| Coil Width | 914mm, 1000mm, 1200mm, 1220mm, 1250mm etc | |

| Forming Speed | 6-10 (m/min) | * Or According To Your Requirement |

| Forming Station | 16-20 Stations | * According To Your Profile Drawings |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Steel Plates Welded | * Individual Station (Optional) |

| Rollers’ Material | 45# | |

| Cutting System | Hydraulic Post Cut | * Hydraulic Servo Tracking Cutter (Optional) |

| Output Way | Roller Table | * Auto Stacker (Optional) |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| Power Supply | 380V 50Hz 3ph | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

Application

influence factor of tile roll forming machine price

- Machine Size and Capacity: The size and production capacity of the tile roll forming machine can significantly affect its price. Machines with larger sizes and higher production capacities tend to be more expensive due to the increased materials and components required for construction.

- Complexity of Design: The complexity of the machine’s design and functionality can also impact its price. Machines with advanced features, precision engineering, and intricate designs may cost more to manufacture, resulting in a higher price.

- Quality of Materials and Components: The quality of materials and components used in the construction of the machine can influence its price. High-quality materials and durable components tend to be more expensive, but they contribute to the machine’s overall performance, reliability, and longevity.

- Brand and Manufacturer: The reputation, brand value, and manufacturing capabilities of the company producing the machine can affect its price. Established and well-known brands often command higher prices due to their reliability, customer support, and brand recognition.

- Customization Options: If the tile roll forming machine offers customization options to meet specific customer requirements, it may come at a higher price. Customized machines involve additional engineering and design work, which can increase manufacturing costs.

- Automation and Technology: Machines equipped with advanced automation features, such as computer numerical control (CNC) systems or sophisticated software integration, are generally more expensive. Higher levels of automation and advanced technology can improve production efficiency, accuracy, and versatility, leading to a higher price.

- Market Demand and Competition: The supply and demand dynamics of the market can influence the pricing of tile roll forming machines. If there is high demand and limited competition, prices may be higher. Conversely, in a competitive market with multiple suppliers, prices may be more competitive.

- Additional Features and Accessories: Optional features and accessories, such as safety devices, monitoring systems, or specialized tooling, can impact the price. The inclusion of additional features beyond the basic machine functionality will likely increase the overall cost.

- After-Sales Support and Warranty: The availability and quality of after-sales support, including technical assistance, spare parts availability, and warranty coverage, can affect the price. Machines with extensive after-sales support and longer warranty periods may have a higher upfront cost.

function of roof panel roll forming machine

The roof panel roll forming machine is a specialized equipment used in the construction industry to manufacture roof panels with consistent shapes and profiles. The machine performs several functions to transform raw materials into finished roof panels. Here are the main functions of a roof panel roll forming machine:

- Material Feeding: The machine takes in raw material, typically coil metal sheets, and feeds them into the forming section. The material is usually steel or aluminum.

- Roll Forming: The heart of the machine is the roll forming section, where a series of rollers and tooling are arranged to shape the metal sheet into the desired profile. The rollers gradually bend the metal as it passes through them, forming it into the specific shape of the roof panel.

- Cutting: Once the metal sheet has been formed into the desired shape, the machine incorporates a cutting mechanism to trim the panel to the required length. Different cutting methods can be used, such as a flying cutoff or a stationary shear, depending on the design of the machine.

- Profile and Notching: Some roof panel roll forming machines may include additional functions for creating specific profiles and notches in the panels. These profiles and notches can provide interlocking features for easy installation and enhanced structural integrity.

- Embossing and Stamping: Certain roof panel designs may require embossing or stamping to add aesthetic or functional features. The machine can be equipped with specialized tools to imprint patterns, logos, or other design elements onto the surface of the roof panels.

- Control and Automation: Modern roof panel roll forming machines often incorporate control systems and automation features. These systems allow for precise control of the forming process, including speed, length measurement, cutting operations, and more. Automation reduces manual intervention and ensures consistent panel production.

- Output and Stacking: As the roof panels are produced, the machine facilitates the smooth discharge and stacking of the finished panels. Conveyor systems or stacking mechanisms are used to collect and organize the panels for further processing or transportation.

advantages of China roof tile roll forming machine

- Cost-Effectiveness: Chinese manufacturers often offer competitive prices for their roof tile roll forming machines. The lower manufacturing and labor costs in China allow them to provide cost-effective solutions compared to machines produced in other countries.

- Technological Advancements: China has made significant advancements in manufacturing technologies, including roll forming machinery. Chinese manufacturers continuously invest in research and development to improve the performance, precision, and automation capabilities of their machines. This results in technologically advanced roof tile roll forming machines that meet or exceed industry standards.

- Customization Options: Chinese manufacturers are known for their flexibility in providing customization options. They can tailor roof tile roll forming machines to meet specific customer requirements, such as different tile profiles, sizes, and materials. This ability to customize allows customers to obtain machines that precisely match their production needs.

- Wide Range of Choices: The Chinese market offers a wide variety of roof tile roll forming machines, catering to different roofing material types, profiles, and production capacities. Customers have the flexibility to choose from a diverse range of machines, ensuring they can find one that aligns with their specific project requirements.

- Quality Assurance: Chinese manufacturers have made significant strides in improving the quality of their products. Many reputable manufacturers follow strict quality control measures to ensure that their roof tile roll forming machines meet international quality standards. They also offer warranty support and after-sales service to ensure customer satisfaction.

- Established Industry Expertise: China has a well-developed manufacturing infrastructure and a large pool of experienced engineers and technicians specializing in roll forming machinery. The country’s expertise in this field has allowed Chinese manufacturers to gain a strong foothold in the global market and build a reputation for delivering reliable and high-quality roof tile roll forming machines.

- Export Capability: China has a robust export capability, and many Chinese manufacturers have established a global presence. This makes it easier for customers from around the world to access and procure roof tile roll forming machines from China, ensuring wider availability and market reach.

Exploring the Different Applications of Width Corrugated Sheet Roll Forming Machine