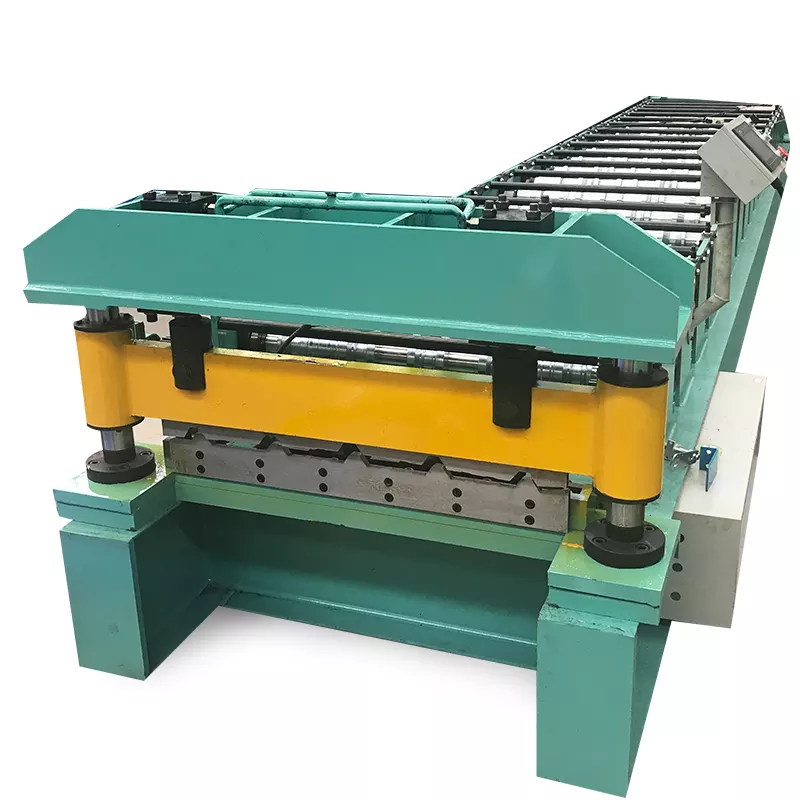

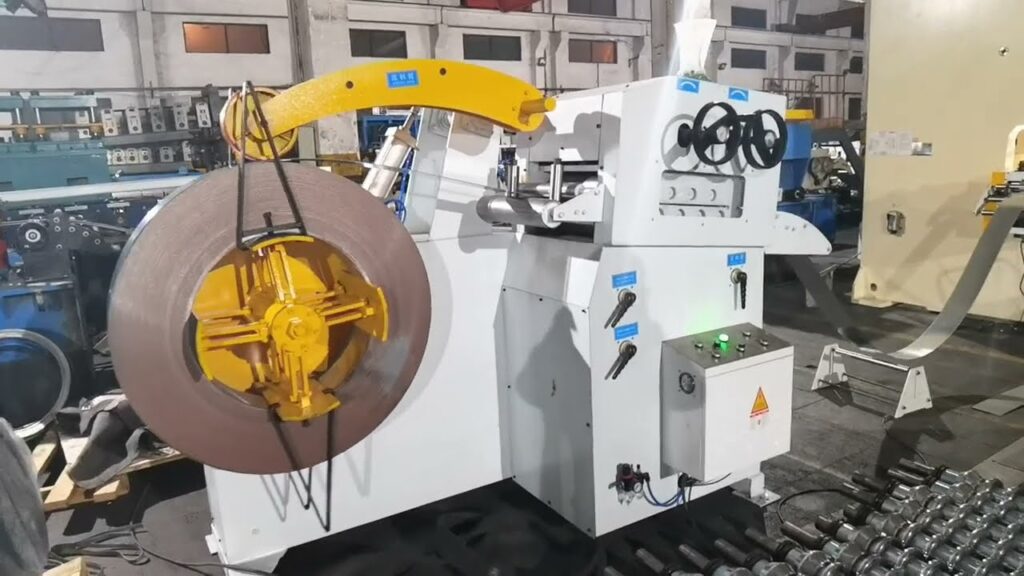

When it comes to the manufacturing industry, one of the most essential tools is the width corrugated sheet roll forming machine. This machine can produce corrugated sheets in a variety of widths, lengths, and thicknesses, making it a versatile technology with numerous applications. From the construction and automotive industries to the packaging and furniture industries, width corrugated sheet roll forming machines have revolutionized the way manufacturers create products. In this post, we will explore the different applications of width corrugated sheet roll forming machines and how they are transforming the manufacturing landscape.

Width Corrugated Sheet Roll Forming Machine for Roofing and cladding

Roofing and cladding are among the most important elements of a building’s exterior. Not only do they protect the building from the elements, but they also contribute to its overall aesthetic appeal. Width corrugated sheet roll forming machines are an essential tool in the production of roofing and cladding materials.

These machines can create different profiles and shapes, depending on the requirements of the building. For example, the machine can create corrugated sheets with U-shaped or V-shaped profiles, or it can produce trapezoidal sheets. This flexibility makes it possible to achieve a wide range of designs, from traditional to modern.

In addition to their aesthetic appeal, corrugated sheets offer several advantages for roofing and cladding. For one, they are lightweight, which makes them easier to transport and install. This can reduce construction time and costs, as well as the need for heavy equipment. Corrugated sheets are also durable and weather-resistant, making them an excellent choice for buildings in areas prone to harsh weather conditions.

Another advantage of using corrugated sheets is their low maintenance requirements. They are easy to clean and do not require painting or sealing, which can save time and money over the lifetime of the building.

Overall, the use of width corrugated sheet roll forming machines has transformed the roofing and cladding industry, allowing for greater flexibility in design and construction while also improving durability and reducing maintenance costs.

Width Corrugated Sheet Roll Forming Machine for Automotive industry

Width corrugated sheet roll forming machines are not just limited to the construction industry; they also have a significant impact on the automotive industry. These machines can create components such as car body panels, trim, and bumpers, which are essential elements of a vehicle’s exterior.

One of the main advantages of using corrugated sheets in the automotive industry is their lightweight and strength properties. Corrugated sheets are made up of multiple layers of materials, which makes them stronger than other materials while still being lightweight. This feature is particularly important for car body panels, where strength and weight reduction are critical factors for vehicle performance.

Another advantage of using width corrugated sheet roll forming machines for automotive applications is the flexibility in design. These machines can create different shapes and profiles, allowing for a wide range of design possibilities. This means that car manufacturers can create unique and innovative designs that set them apart from their competitors.

Additionally, the use of corrugated sheets for automotive applications can lead to cost savings. They are more cost-effective than other materials, such as aluminum or carbon fiber, and are easier to manufacture. This translates into a lower production cost, which can help manufacturers save money without sacrificing quality.

In summary, the use of width corrugated sheet roll forming machines has revolutionized the automotive industry by providing lightweight and durable components, flexible design options, and cost savings. It’s no wonder why this technology is widely used by car manufacturers worldwide.

Width Corrugated Sheet Roll Forming Machines for Packaging industry

-

Vineyard Post Roll Forming Machine

Vineyard Post Roll Forming Machine -

Auto Size Changeable Sigma Purlin Roll Forming Machine

Auto Size Changeable Sigma Purlin Roll Forming Machine -

PV Mounting Bracket C Shape Profile Roll Forming Machine

PV Mounting Bracket C Shape Profile Roll Forming Machine -

C Z Purlin Channel Cold Roll Forming Machine Full Auto Galvanized Steel Profile

C Z Purlin Channel Cold Roll Forming Machine Full Auto Galvanized Steel Profile -

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile)

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile) -

PV Mounting Bracket Z Shape Profile Roll Forming Machine

PV Mounting Bracket Z Shape Profile Roll Forming Machine

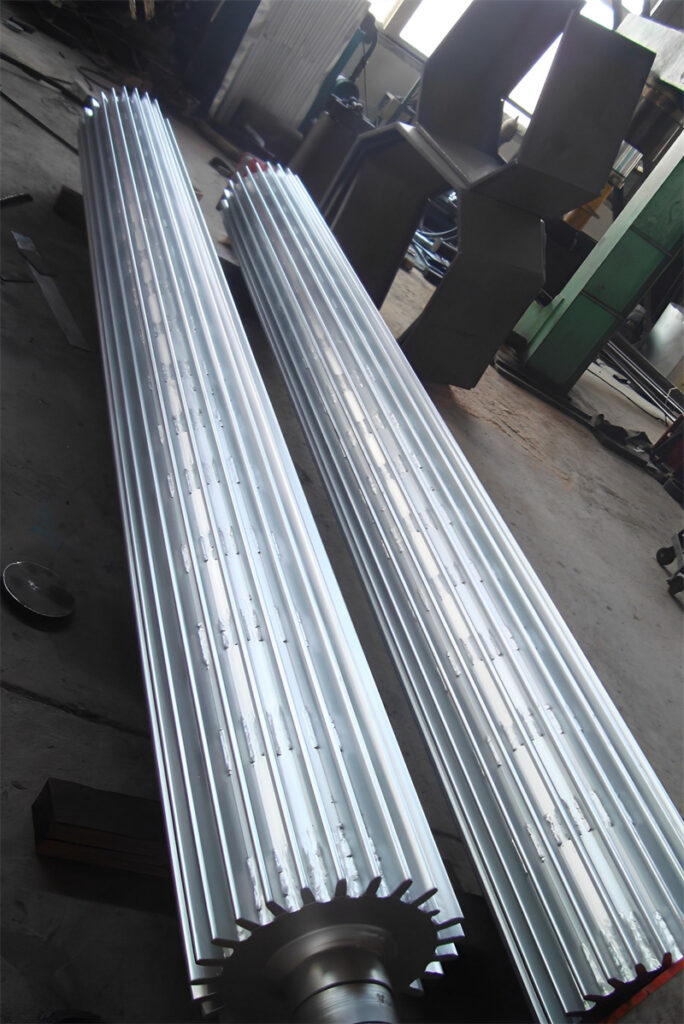

Width corrugated sheet roll forming machines are essential in the production of packaging materials, such as cardboard boxes and containers. These machines are capable of producing corrugated cardboard in various thicknesses and strengths, making them suitable for a wide range of packaging applications.

The corrugated cardboard produced by these machines consists of three layers: an outer liner, a fluted medium, and an inner liner. The fluted medium provides strength and rigidity to the cardboard, making it suitable for use in packaging. The width corrugated sheet roll forming machines can produce different profiles of the fluted medium, resulting in different thicknesses and strengths of the final product.

One of the main benefits of using corrugated cardboard for packaging is its durability. It can withstand rough handling, stacking, and transportation without breaking or damaging the contents inside. Additionally, corrugated cardboard is lightweight and can be easily cut, folded, and molded into different shapes and sizes, making it versatile for various packaging applications.

Corrugated cardboard is also environmentally friendly. It is made from recycled materials and is 100% recyclable. This makes it an ideal choice for companies that want to reduce their carbon footprint and minimize waste.

Another advantage of using width corrugated sheet roll forming machines for packaging applications is their high production speed. These machines can produce large quantities of corrugated cardboard quickly, which is essential for meeting the demands of high-volume packaging operations.

In conclusion, the use of width corrugated sheet roll forming machines has transformed the packaging industry by providing durable, lightweight, and versatile packaging materials. The ability to create different thicknesses and strengths of corrugated cardboard has also enabled companies to customize their packaging to meet specific needs while reducing their environmental impact.

Width Corrugated Sheet Roll Forming Machines for Other applications

Width corrugated sheet roll forming machines are not limited to just the construction, automotive, and packaging industries. There are several other applications for this technology, which can be found in the production of furniture, appliances, toys, and more.

In the furniture industry, corrugated sheets are commonly used as internal supports for pieces such as chairs, tables, and cabinets. Corrugated sheets are lightweight yet strong, making them a great choice for these applications. Additionally, they are easy to cut, shape, and fasten, allowing for efficient production and assembly.

In the appliance industry, corrugated sheets are used to create internal and external components for appliances such as refrigerators, air conditioners, and washing machines. The strength and durability of corrugated sheets make them ideal for these applications, where components must withstand the weight and stress of the appliances’ operation.

In the toy industry, corrugated sheets are used to create durable and lightweight play structures such as forts, castles, and tunnels. The versatility of corrugated sheets allows for creative and imaginative designs, while also providing a safe and sturdy play environment.

One of the significant benefits of using corrugated sheets in these industries is the cost savings. Corrugated sheets are typically less expensive than other materials such as wood, metal, or plastic, making them an economical choice for manufacturers. Additionally, corrugated sheets are recyclable, making them a sustainable and environmentally friendly material.

Overall, the use of width corrugated sheet roll forming machines has expanded beyond the traditional industries and into various applications such as furniture, appliances, toys, and more. The benefits of using corrugated sheets in these industries include their strength, durability, versatility, and cost-effectiveness, making them a popular choice among manufacturers.

In summary, width corrugated sheet roll forming machines are a versatile and essential tool in many industries, including construction, automotive, packaging, furniture, appliances, toys, and more. These machines can create different shapes and profiles of corrugated sheets, providing flexibility in design while also offering strength, durability, and cost-effectiveness. The use of corrugated sheets has transformed these industries by providing lightweight, sustainable, and customizable solutions for a wide range of applications. As technology continues to evolve, we can expect to see even more innovative applications of width corrugated sheet roll forming machines in the future.