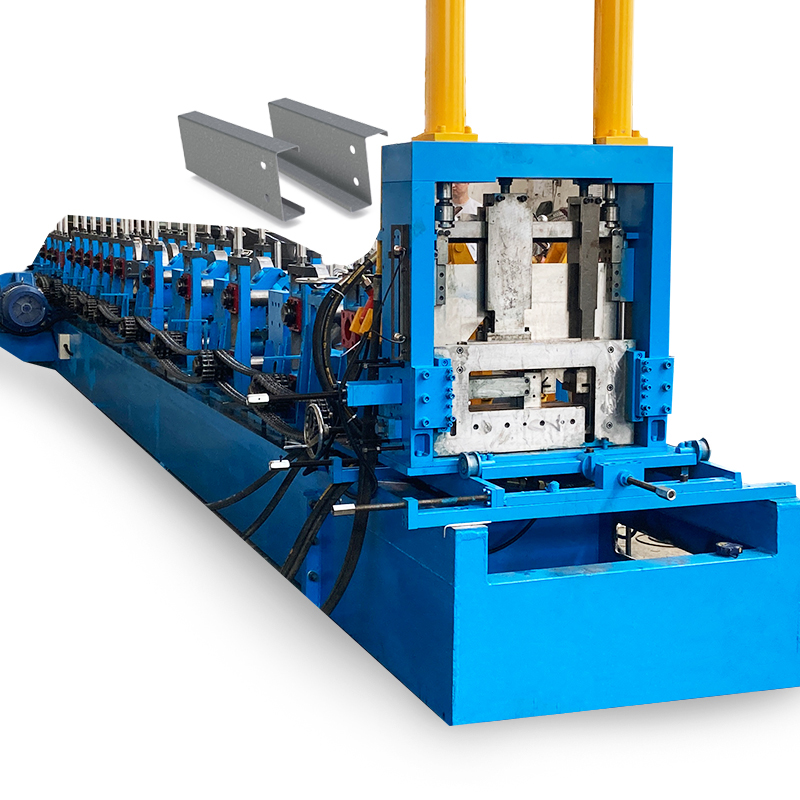

If you’re in the business of manufacturing C channel profiles, you know how important it is to have the right equipment to get the job done efficiently and effectively. One crucial piece of equipment for this task is a C channel roll forming machine. Choosing the right machine can be a daunting task, with many factors to consider. In this post, we’ll go over what to consider when choosing a C channel roll forming machine to help you make the best decision for your business.

Production Requirements with C Channel Roll Forming Machine

The first factor to consider when choosing a C channel roll forming machine is the production requirements of your business. This includes the required output and the type of C channel profile you want to manufacture.

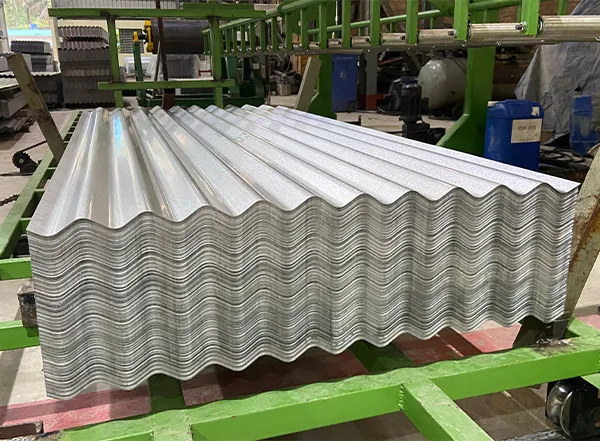

If your business has high production demands, you will need a machine that can handle high-volume output. Look for a machine with a high production speed and a large capacity for raw materials.

Additionally, you should consider the specific type of C channel profile you want to manufacture. There are various sizes and shapes of C channels, and not all machines are capable of producing all types. Some machines are designed for smaller profiles, while others can handle larger or more complex profiles.

Understanding your production requirements is crucial in selecting a C channel roll forming machine that can meet your business’s needs. Be sure to consider both your current and future production needs, as you don’t want to invest in a machine that won’t be able to keep up with your growing business.

Material Compatibility of C channel roll forming machine

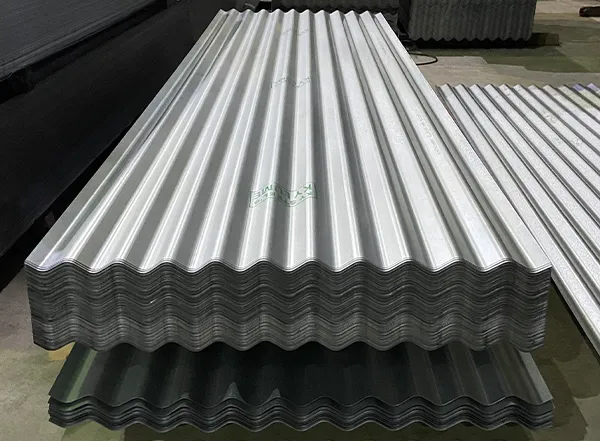

Another important factor to consider when choosing a C channel roll forming machine is material compatibility. Different roll forming machines are designed to work with specific types of materials, such as steel, aluminum, or copper.

It’s important to choose a machine that is compatible with the materials you plan to use. Using the wrong material on a machine can cause damage to the machine and potentially produce subpar C channel profiles.

In addition to material compatibility, you should also consider the thickness and strength of the materials you plan to use. Some machines may be better suited for thinner or weaker materials, while others can handle thicker or stronger materials.

When selecting a C channel roll forming machine, be sure to consider the materials you plan to use both now and in the future. Choosing a machine that can handle a variety of materials can be a wise investment for your business.

Machine Quality of C channel roll forming machine

When choosing a C channel roll forming machine, it’s important to consider the quality of the machine itself. The quality of the machine will directly impact the quality of your C channel profiles, so it’s crucial to invest in a high-quality machine.

To ensure the machine’s quality, consider the manufacturer’s reputation. Look for a manufacturer with a proven track record of producing reliable and durable machines. You can research online reviews and ask for recommendations from other businesses in your industry.

Additionally, consider the quality of the components used in the machine. High-quality components will be more durable and reliable, leading to better performance and longevity of the machine. Look for machines with components made by reputable manufacturers known for their quality.

Lastly, consider any warranties or guarantees offered by the manufacturer. A warranty or guarantee can provide peace of mind that the machine will be reliable and can be repaired or replaced if any issues arise.

Investing in a high-quality C channel roll forming machine may come with a higher price tag, but it can be worth it in the long run. A reliable and durable machine can produce high-quality C channel profiles consistently, leading to satisfied customers and repeat business.

Automation of C channel roll forming machine

Automation is another important factor to consider when choosing a C channel roll forming machine. Automating the roll forming process can increase productivity and reduce labor costs, making it a valuable investment for many businesses.

Different roll forming machines offer varying levels of automation. Some machines require manual loading and unloading of materials, while others have automatic material handling systems. Some machines also have automatic tool change capabilities, reducing downtime between jobs.

When considering the level of automation you need, think about the size of your business and your production goals. If you have a large operation with high production demands, investing in a fully automated machine may be worth the investment. However, if your business is smaller and has lower production demands, a partially automated machine may be more appropriate.

It’s also important to consider the ease of use of the machine’s automation features. Look for machines with user-friendly controls and intuitive interfaces, as this can save time and reduce the need for extensive training.

Overall, investing in a C channel roll forming machine with automation capabilities can help increase productivity, reduce labor costs, and improve efficiency in your manufacturing process.

Maintenance and Support of C channel roll forming machine

Regular maintenance is crucial for ensuring that your C channel roll forming machine is running at peak efficiency and producing high-quality profiles. When selecting a machine, it’s important to consider how easy it is to maintain and repair, as well as the level of support provided by the manufacturer.

Look for a machine that is easy to maintain and repair, with easily accessible components and clear instructions for maintenance and repairs. Ideally, the machine should require minimal downtime for maintenance and repairs to avoid disrupting your production schedule.

In addition to ease of maintenance, consider the level of support provided by the manufacturer. Look for a manufacturer with a good reputation for customer support, including responsive customer service and technical support. A manufacturer that offers training and education on machine operation and maintenance can also be valuable for your business.

It’s important to have a plan in place for regular maintenance of your roll forming machine to ensure it continues to operate at peak efficiency. This can include scheduled maintenance, such as oil changes and inspections, as well as regular cleaning and upkeep.

By investing in a machine that is easy to maintain and comes with good customer support, you can minimize downtime and keep your production running smoothly.

Choosing the right C channel roll forming machine is essential for any business involved in the manufacturing of C channel profiles. Production requirements, material compatibility, machine quality, automation, and maintenance and support are all critical factors to consider when selecting a machine. Investing in a high-quality machine that meets your specific production needs and offers reliable and user-friendly automation capabilities can help increase efficiency and productivity while reducing labor costs. Additionally, regular maintenance and support from the manufacturer can help ensure that the machine runs at peak efficiency and provides consistent, high-quality results.