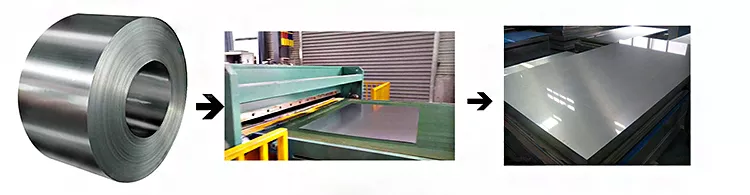

Sunway automatic cut to length line is used for uncoiling, leveling, and automatic length measuring and cutting. Electrical controlling by AC variable frequency and servo control, which has better length precision and efficiency.

Product Details

Stand Base

Select high quality steel as raw material with high strength and heavy duty, which has strong resistance to deformation.

Motor

Adopt top brand motor for drive system, more stable and effective.

High Automatic

Cut to length machine adopts PLC system. Customer can set production quantity, production speed on control cabinet.

Customization

Senior and experienced engineer control the whole process for your customize.

Product Parameters

| Processing Thickness | 0.1~3mm |

| Processing Width | 100-2000mm |

| Cut To Length Accuracy | ±1.5 mm |

| Cutting Speed | 1-200m/min |

| Coil Inner Diameter | 500/610 mm |

| Coil Outer Diameter | ≤2000 mm |

| Cut To Length Range | 500~4000mm |

| Sheet Leveling Flatness | ≤±1.5mm/m² |

| Length Tolerance | ≤±1.5mm /m² |

| Diagonal Tolerance | ≤±1.2mm/m² |

| Levelling Precision | ≤2mm/m² |

| Cut Length | 500~3000mm |

The parameters mentioned above are for reference, and the machine can be customized.

advantage of China cut to length line machine

China has emerged as a prominent manufacturer of cut-to-length line machines and offers several advantages in terms of quality, cost-effectiveness, and technological advancements. Here are some advantages of China-made cut-to-length line machines:

- Cost-Effective Manufacturing: China is known for its competitive manufacturing costs, which translates into relatively lower prices for cut-to-length line machines. Chinese manufacturers often offer cost-effective solutions without compromising on quality.

- Wide Range of Options: China has a vast number of manufacturers producing cut-to-length line machines, providing customers with a wide range of options to choose from. This allows buyers to find machines that meet their specific requirements in terms of capacity, cutting capabilities, and automation features.

- Technological Advancements: Chinese manufacturers have made significant advancements in the design and technology of cut-to-length line machines. They incorporate advanced control systems, automation features, and precision cutting mechanisms to enhance efficiency and accuracy.

- Customization and Flexibility: Chinese manufacturers are often open to customizing cut-to-length line machines according to specific customer needs. They can modify the machine’s specifications, cutting capacities, and other features to meet unique requirements.

- Quality Standards: Over the years, China has improved its manufacturing processes and quality control systems. Many Chinese manufacturers adhere to international quality standards and certifications, ensuring that their cut-to-length line machines meet industry requirements.

- Strong Supplier Network: China has a robust supplier network that supports the manufacturing of cut-to-length line machines. This ensures a steady supply of components, spare parts, and technical support, contributing to the overall reliability and maintenance of the machines.

- Export Experience: Chinese manufacturers have extensive experience in exporting cut-to-length line machines to various countries around the world. They understand the logistical requirements and can provide efficient shipping and after-sales support to customers globally.

It’s important to note that while China offers many advantages in terms of cut-to-length line machine manufacturing, it’s essential to conduct thorough research, evaluate manufacturers’ reputations, and consider customer reviews before making a purchasing decision.

how much does cut to length line machine?

The cost of a cut-to-length line machine can vary significantly depending on various factors such as the machine’s specifications, capacity, features, and the manufacturer or supplier. Additionally, market conditions, location, and currency exchange rates can also influence the pricing. As a result, it is challenging to provide an exact price without specific details.

Generally, cut-to-length line machines can range in price from tens of thousands to several hundred thousand dollars. Basic models with lower cutting capacities and fewer automation features tend to be more affordable, while larger, high-capacity machines with advanced automation and precision cutting mechanisms can be more expensive.

It’s important to note that pricing information may be obtained by contacting manufacturers, suppliers, or distributors directly. They can provide detailed quotations based on your specific requirements and provide additional information regarding installation, maintenance, and after-sales support.

When considering the cost of a cut-to-length line machine, it is crucial to evaluate factors such as the machine’s quality, reliability, warranty, and the reputation of the manufacturer or supplier. Additionally, factors like ongoing maintenance, spare parts availability, and customer support should also be taken into account to ensure a successful investment.

Reviews

There are no reviews yet.