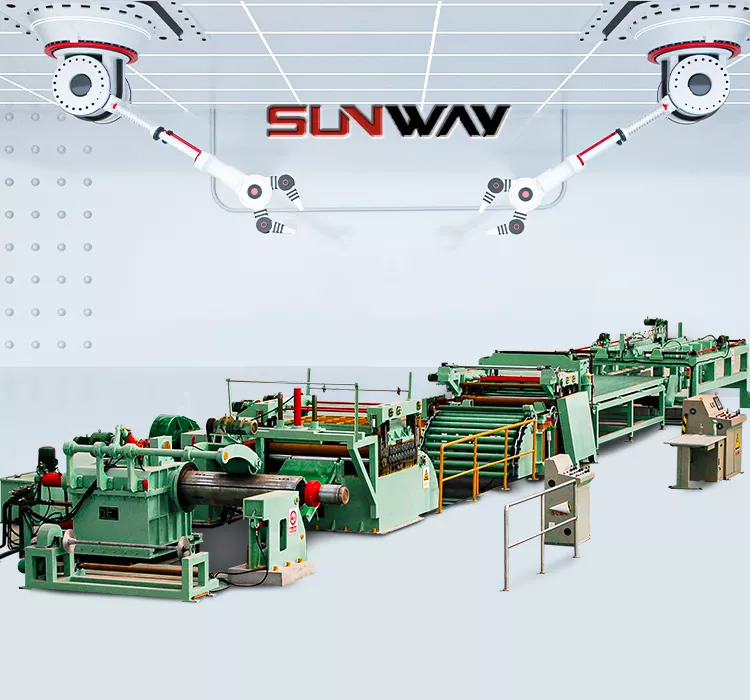

Sunway automatic cut to length line is used for uncoiling, leveling, and automatic length measuring and cutting. Electrical controlling by AC variable frequency and servo control, which has better length precision and efficiency.

Cut To Length Line Machine Details

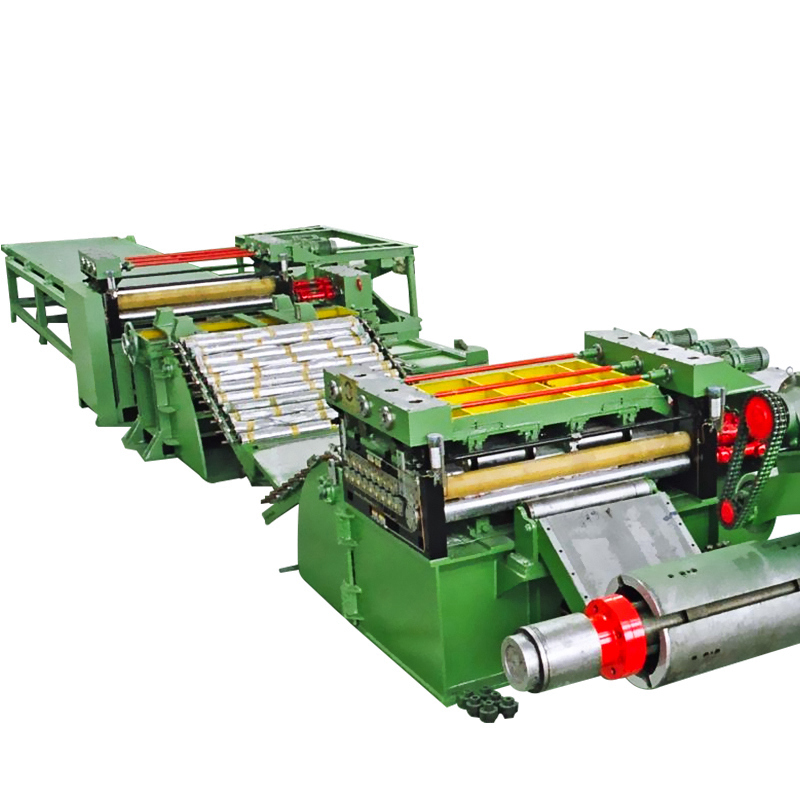

Stand Base

Select high quality steel as raw material with high strength and heavy duty, which has strong resistance to deformation.

Motor

Adopt top brand motor for drive system, more stable and effective.

High Automatic

Cut to length machine adopts PLC system. Customer can set production quantity, production speed on control cabinet.

Customization

Senior and experienced engineer control the whole process for your customize.

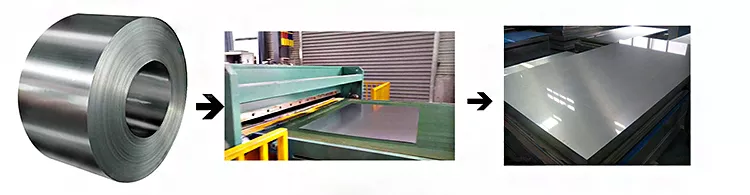

What is the working principle of cut to length line machine?

A cut-to-length line machine is an industrial equipment used in metal processing to cut coils of metal into specific lengths or sheets. The working principle of a typical cut-to-length line machine involves several steps:

- Coil Loading: The process begins by loading a coil of metal, such as steel or aluminum, onto an uncoiler. The uncoiler feeds the coil into the machine for further processing.

- Straightening: The coil passes through a straightening unit that removes any residual coil set or curvature. This ensures that the metal is flat and ready for cutting.

- Feeding: The straightened coil is then fed into a feeding system that precisely advances the metal to the cutting station. The feeding system usually consists of rollers or grippers that grip and advance the material.

- Measurement: At the cutting station, the cut-to-length machine measures the desired length of the metal. This can be done using various methods, such as optical sensors, laser measurement systems, or encoder wheels.

- Cutting: Once the measurement is obtained, the machine initiates the cutting process. The cutting mechanism can vary depending on the machine design, but common methods include hydraulic shearing, rotary disc cutting, or guillotine cutting. The metal is cut accurately based on the measured length.

- Stacking/Discharging: After the metal is cut, the cut-to-length line machine typically stacks or discharges the cut pieces. This can involve stacking them in piles or transferring them to a conveyor for further processing or packaging.

- Automation and Controls: Cut-to-length line machines are often equipped with automation and control systems. These systems ensure precise measurements, accurate cutting, and efficient operation. They can also include features such as programmable length settings, batch processing, and quality monitoring.

The entire process is usually automated and controlled through a central control panel, allowing operators to set parameters, monitor production, and make adjustments as needed.

Overall, the working principle of a cut-to-length line machine involves coil loading, straightening, feeding, measurement, cutting, and stacking/discharging. These machines are widely used in various industries that require precise metal cutting and sheet production.

application of simple cut to length line machine

A simple cut-to-length line machine has a range of applications across industries that require accurate cutting and processing of metal coils. Some common applications include:

- Steel Service Centers: Cut-to-length line machines are extensively used in steel service centers to process steel coils into precise lengths. These centers supply cut-to-length sheets to various industries, including construction, automotive, and manufacturing.

- Metal Fabrication: Metal fabrication shops often utilize cut-to-length line machines to cut coils of metal, such as steel, aluminum, or copper, into specific lengths for further fabrication processes. These cut pieces can be used in the production of metal components, structures, or assemblies.

- Automotive Industry: Cut-to-length line machines play a vital role in the automotive industry for producing metal sheets or strips of precise lengths. These sheets can be used for manufacturing automotive body panels, frames, chassis components, and other metal parts.

- Appliance Manufacturing: The appliance manufacturing industry employs cut-to-length line machines to cut metal coils into required lengths for producing various appliances such as refrigerators, washing machines, and air conditioners. The cut pieces can serve as panels, doors, or other structural components.

- Construction Industry: In construction, cut-to-length line machines are used to cut metal coils into customized lengths for roofing, cladding, and other building applications. This allows for efficient material utilization and precise fitting of metal sheets.

- Electrical Industry: Cut-to-length line machines are utilized in the electrical industry for cutting coils of copper or aluminum into specific lengths required for manufacturing electrical wires, cables, and conductors.

- Packaging Industry: Cut-to-length line machines are employed in the packaging industry to cut metal coils into precise lengths for producing packaging materials, such as metal sheets used for containers, cans, or lids.

These are just a few examples of how a simple cut-to-length line machine can find applications in various industries. The machine’s ability to accurately cut metal coils into specific lengths provides efficiency, precision, and customization options for different manufacturing processes.

Reviews

There are no reviews yet.