As a business owner, the decision to invest in a siding roll forming machine can be a big one. Not only do you need to consider the cost and maintenance of this large piece of equipment, but you also need to make sure that it will fit into your existing production line. In this article, we’ll provide you with an ultimate guide on how to buy the best siding roll forming machine for your business.

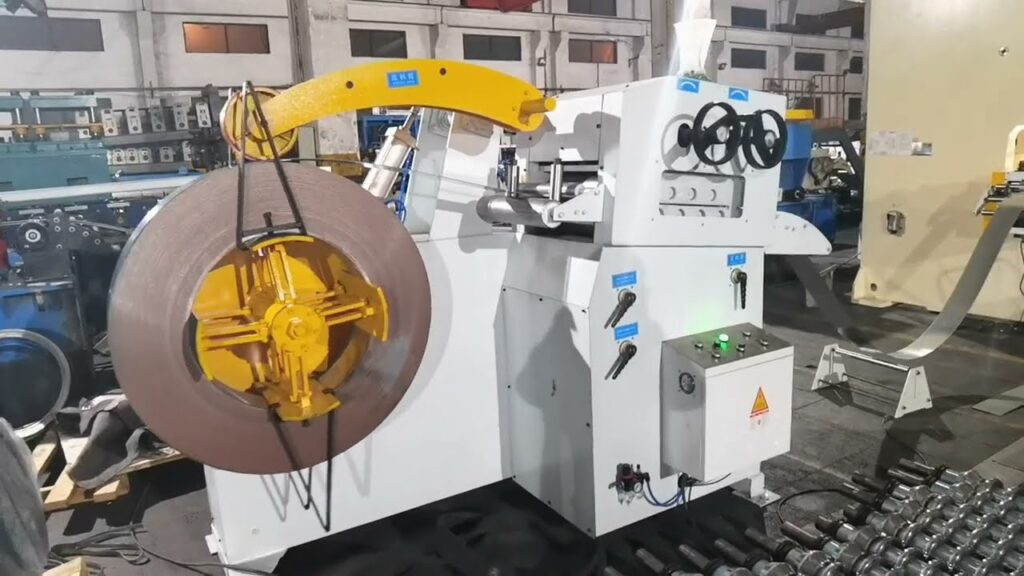

What is a Siding Roll Forming Machine?

A siding roll forming machine is a type of machine that is used to create sidings. Sidings are a type of material that is used to cover the outside of a building. They are made from a variety of materials, including metal, plastic, and vinyl.

Sidings can be used for both residential and commercial buildings. They are available in a variety of colors and styles, which allows you to choose the perfect siding for your home or business. Siding can be installed by a professional contractor or by yourself, if you have the proper tools and equipment.

Types Of Siding Roll Forming Machines

There are many different types of siding roll forming machines out there on the market, and it can be difficult to decide which one is right for your business. Here is a rundown of some of the most popular types of machines so that you can make an informed decision:

- Single-head siding roll forming machine: This type of machine is ideal for businesses that produce small to medium batches of siding. It is a relatively simple machine that can be operated by one person.

- Multi-head siding roll forming machine: This type of machine is great for businesses that produce large batches of siding. It has multiple heads that can operate simultaneously, which helps to speed up production.

- Custom siding roll forming machine: If you have specific requirements for your siding, then you may want to consider investing in a custom roll forming machine. These machines are designed to meet your specific needs and can be customized to produce the exact results you desire.

Differences Between Vertical And Horizontal Siding Roll Forming Machines

When it comes to siding roll forming machines, there are two main types: vertical and horizontal. Each type has its own advantages and disadvantages that you need to consider before making a purchase.

Vertical siding roll forming machines are typically more expensive than horizontal machines, but they offer a number of advantages. First, vertical machines take up less space in your factory since they are taller than horizontal machines. Second, vertical machines can produce longer lengths of siding, so you won’t have to worry about joints as much. Finally, vertical machines typically have higher production speeds than horizontal machines.

Horizontal siding roll forming machines are less expensive than vertical machines, but they have some disadvantages. First, horizontal machines can’t produce as long lengths of siding as vertical machines. Second, horizontal machines take up more space in your factory since they are wider than vertical machines. Third, horizontal machines typically have lower production speeds than vertical machines.

So, which type of machine is best for your business? It really depends on your specific needs and requirements. If you need to produce long lengths of siding quickly, then a vertical machine is probably the best option for you. If you have limited space in your factory and you need to be able to produce shorter lengths of siding, then a horizontal machine is probably the better choice for you. Ultimately, it’s important to weigh all the factors carefully before making a decision.

Benefits of Using a Siding Roll Forming Machine

-

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Cable Ladder Roll Forming Machine

Cable Ladder Roll Forming Machine -

PV Mounting Bracket C Shape Profile Roll Forming Machine

PV Mounting Bracket C Shape Profile Roll Forming Machine -

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine -

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile)

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile) -

PV Mounting Bracket Z Shape Profile Roll Forming Machine

PV Mounting Bracket Z Shape Profile Roll Forming Machine

There are many benefits of using a siding roll forming machine for your business. They can help you increase production, improve quality, and reduce costs.

Here are some of the top benefits of using a siding roll forming machine:

- Increased Production

Roll forming machines can help you increase production by up to 50%. This means that you can produce more products in a shorter amount of time, which can help you meet customer demand and grow your business.

- Improved Quality

Using a roll forming machine can also help improve the quality of your products. This is because the machine creates a consistent product with fewer imperfections. As a result, your products will be more likely to meet customer expectations and stand out from the competition.

- Reduced Costs

Roll forming machines can also help reduce costs associated with production. This is because they are faster and more efficient than traditional methods, such as stamping or welding. Additionally, roll forming machines require less energy to operate, which can further lower your costs.

Factors To Consider For Choosing A Siding Roll Forming Machine For Your Business

If you are in the market for a siding roll forming machine, there are a few factors that you will need to take into account in order to choose the best one for your business. Here are a few of the most important factors to keep in mind:

- The type of siding that you will be producing. There are different machines designed for different types of siding, so you will need to make sure that you choose a machine that is designed for the type of siding that you will be producing.

- The thickness of the siding. This is an important factor to consider because it will affect the speed at which the machine can produce the siding and also the quality of the finished product.

- The width of the siding. The width of the siding is another important factor to consider because it will determine how many panels can be produced per hour and also how wide each panel can be.

- The length of the siding. This is an important factor to consider because it will determine how many feet of siding can be produced per hour and also how long each panel can be.

- The weight of the siding. This is an important factor to consider because it will determine how much force is required to operate the machine and also how much weight the machine can handle.

Tips for Buying a Machine

When investing in a siding roll forming machine for your business, there are a few key factors to keep in mind in order to get the most out of your purchase. Below are some tips to consider when shopping for a siding roll forming machine:

- Know Your Budget

Before beginning your search for a siding roll forming machine, it is important to have a clear idea of how much you are willing to spend. This will help you narrow down your options and find a machine that fits both your needs and your budget.

- Consider Your Production Needs

How much siding will you need to produce on a daily or weekly basis? What types of projects will you be using the machine for? Answering these questions will help you determine the size and capabilities of the machine you need.

- Research Different Brands & Models

There are many different brands and models of siding roll forming machines on the market today. It is important to do your research in order to find the best option for your business needs. Read online reviews, compare prices, and ask other businesses in your industry for recommendations.

- Invest in Quality

A siding roll forming machine is a significant investment for any business, so it is important to choose a quality option that will stand the test of time. Look for machines that are made from durable materials and come with a warranty or guarantee from the manufacturer.

Maintenance and Upkeep Considerations

As with any major purchase for your business, you’ll want to consider the maintenance and upkeep requirements of your siding roll forming machine before making a final decision. Here are a few things to keep in mind:

- Regular cleaning and lubrication of your machine will help to extend its lifespan and keep it running smoothly.

- Be sure to consult your owner’s manual for specific maintenance instructions for your model.

- It’s always a good idea to have spare parts on hand in case something does break or wear out over time.

Conclusion

At the end of the day, you want to make sure that you purchase the right siding roll forming machine that fits your business needs. Take into consideration your budget and all of the features offered by each model before making a decision. With our guide above, we hope that it is easier for you to find out which type best suits your business so that you can invest in one without any regret.