Are you considering investing in a double layer roll forming machine for your business? This article will discuss the various benefits of doing so, from increased efficiency and cost savings to improved product quality and durability. Discover how this versatile machine can help you streamline production and increase profits!

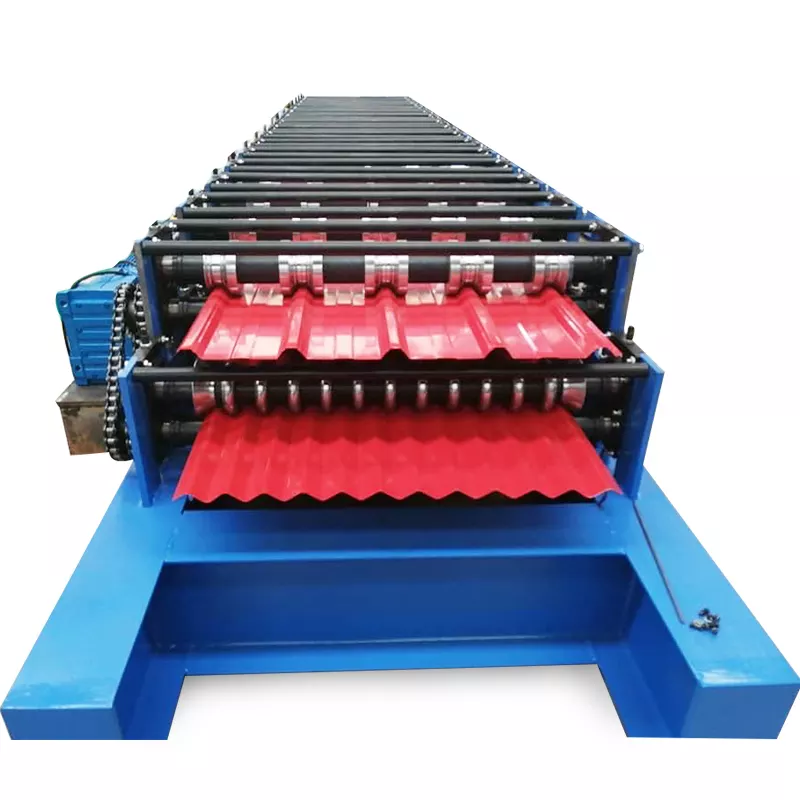

what is a Double Layer Roll Forming Machine?

A double layer roll forming machine is simply two single layer machines placed side-by-side so that two strips can be processed simultaneously. This type of machine is often used when processing long strips or when there are space constraints since it essentially contains two machines in one.

Benefits of Investing in a Double Layer Roll Forming Machine

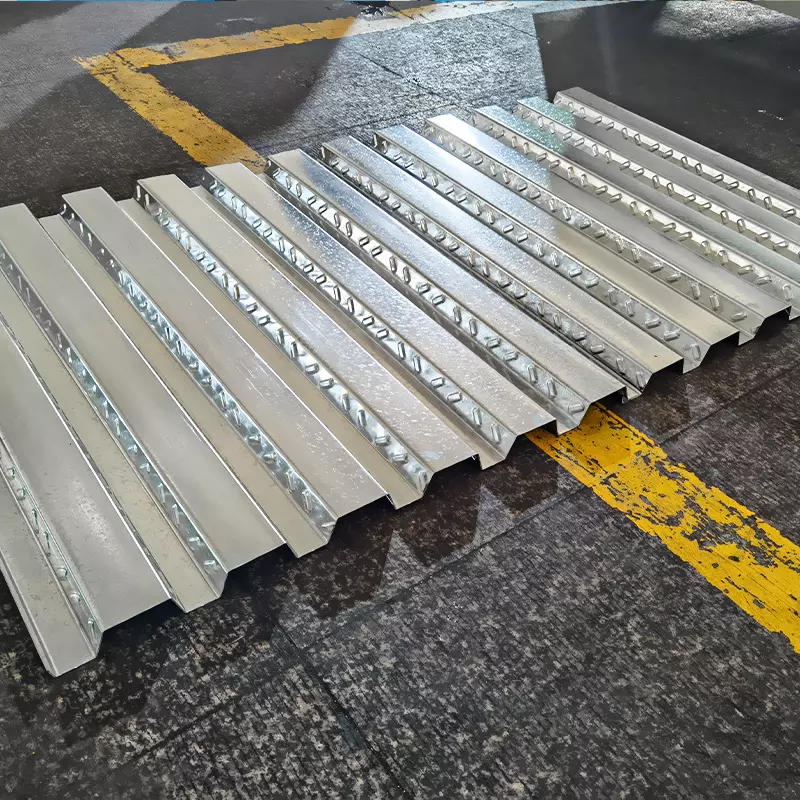

There are many benefits of investing in a double layer roll forming machine for your business. One benefit is that you will be able to produce two products at the same time with one machine. This can help you save money on labor and production costs. Additionally, you can use different materials for each layer, meaning that you can create unique products that stand out from the competition.

Another advantage of owning a double layer roll forming machine is that you can change the order of the layers quickly and easily. This means that you can experiment with different product designs and find the perfect combination for your business. You also have more control over the final product, as you can ensure that each layer is exactly how you want it.

Finally, investing in a double layer roll forming machine shows potential customers that you are serious about your business and are willing to invest in the latest technology. This can help you attract new customers and grow your business.

Types of Double Layer Roll Forming Machines Available

There are a few different types of double layer roll forming machines available on the market today. Depending on your specific needs, one type may be better suited for your business than another. Here is a brief overview of the different types of machines available:

- Single-pass double layer roll forming machine: This type of machine is designed for businesses that produce long, continuous sheets of metal. The single-pass design means that the machine can quickly and efficiently produce large quantities of metal products.

- Multi-pass double layer roll forming machine: This type of machine is ideal for businesses that need to produce shorter lengths of metal product. The multi-pass design allows the machine to make multiple passes over the metal sheet, which results in a shorter overall production time.

- Custom double layer roll forming machine: If you have specific requirements for your metal products, you may want to consider investing in a custom double layer roll forming machine. These machines are designed to meet your specific needs and can be customized to produce any length or width of product you need.

Considerations When Choosing a Machine

When you are looking for a machine to invest in for your business, there are a few considerations you should take into account before making your decision. The first is the type of business you have. If you run a construction company, for example, you will need a different machine than if you manufacture roofing materials.

The second consideration is the size of your business. A small business will not need the same size or type of machine as a large corporation. You should also consider the amount of production you need to do. If you only need a few parts made, then investing in a small machine may be the best option.

The third consideration is the cost of the machine. You want to make sure that you are getting a good deal on the machine and that it will fit into your budget. There are many different types and sizes of machines available, so be sure to shop around and compare prices before making your final decision.

Fourth, you want to think about maintenance and repair costs. Some machines require more maintenance than others, so be sure to factor this into your decision-making process. You also want to make sure that you can get replacement parts easily if something breaks on the machine.

Fifth, consider the warranty that comes with the machine. This can protect you in case something goes wrong with the machine and it needs to be replaced or repaired.

Finally, think about training costs associated with using the machine. If you are not familiar with

Maintenance and Care for Your Machine

If you are considering investing in a double layer roll forming machine for your business, it is important to understand the maintenance and care that is required to keep the machine running smoothly. Here are some tips:

- Always read the manual before operating the machine. This will ensure that you understand how to properly use and maintain the machine.

- Inspect the machine regularly for any wear or damage. If any parts need to be replaced, be sure to order the correct replacement parts from the manufacturer.

- Lubricate the moving parts of the machine on a regular basis according to the manufacturer’s instructions. This will help keep the machine running smoothly and prevent premature wear.

- When not in use, store the machine in a clean, dry area out of direct sunlight.

By following these simple tips, you can ensure that your double layer roll forming machine will provide years of reliable service.

Conclusion

Investing in a double layer roll forming machine is a great way to boost production and increase the efficiency of your business. Not only are they cost-efficient, but they provide quality results that will exceed customer expectations. By investing in this type of machinery now, you can ensure that your business remains ahead of the competition and continues to grow for years to come. So why not take advantage of this opportunity today and make investing in a double layer roll forming machine part of your success story?