When it comes to metal roofing tile roll forming machines, there are a myriad of options available on the market. But choosing the right one for your project can be a daunting task. In this article, we’ll explore the basics of metal roofing tile roll forming machines to help you make an informed decision and find the right machine for your needs.

What is a Metal Roofing Tile Roll Forming Machine?

A metal roofing tile roll forming machine is a specialized piece of equipment that helps to create metal roofing tiles. These machines are typically used in commercial or industrial settings, and they can be quite expensive. If you’re thinking about purchasing one for your project, it’s important to understand how they work and what factors you should consider before making your purchase.

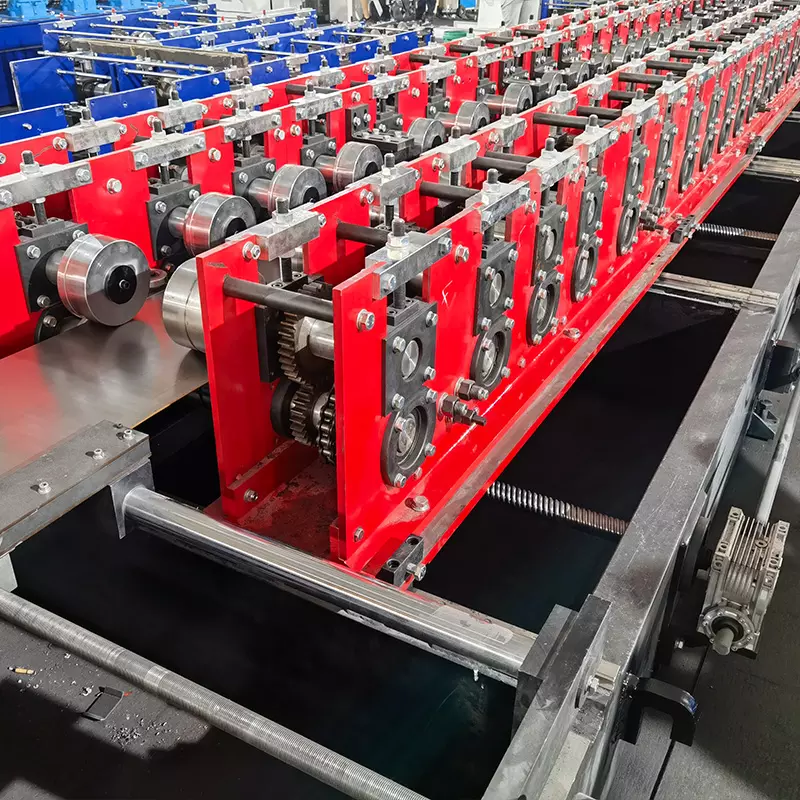

Metal roofing tile roll forming machines work by taking a large sheet of metal and running it through a series of dies. These dies help to shape the metal into the desired tiles. The machine will then cut the tiles to the correct size and finally punch out any holes that need to be present in the final product.

Benefits of Using a Metal Roofing Tile Roll Forming Machine

A metal roofing tile roll forming machine can offer many benefits for your roofing project. Here are some of the benefits of using a metal roofing tile roll forming machine:

- Increased productivity – A metal roofing tile roll forming machine can increase productivity by up to 30%. This means that you can get your roofing project done faster and with less manpower.

- Better quality – When you use a metal roofing tile roll forming machine, you can be assured of getting a better quality product. This is because the machine will help to ensure that the tiles are cut correctly and have a consistent shape.

- Greater flexibility – A metal roofing tile roll forming machine offers greater flexibility when it comes to choosing the right size and shape of tiles for your project. You can also choose from a variety of colors and finishes to suit your taste.

- Lower costs – When you use a metal roofing tile roll forming machine, you can save money on labor costs as well as materials. This is because the machine can produce large quantities of tiles at one time, so you don’t have to pay for multiple production runs.

- Environmentally friendly – Metal roofing tiles are made from recycled materials, so they are an environmentally friendly option for your roofing project.

-

Standing Seam Roof Panel Curving Machine

Standing Seam Roof Panel Curving Machine -

Barrel Corrugated Roll Forming Machine

Barrel Corrugated Roll Forming Machine -

Hydraulic Roof Sheet Curving Machine

Hydraulic Roof Sheet Curving Machine -

Stand Seaming Roof Panel Roll Forming Machine

Stand Seaming Roof Panel Roll Forming Machine -

Downspout Pipe Roll Forming Machine

Downspout Pipe Roll Forming Machine -

Gutter Roll Forming Machine

Gutter Roll Forming Machine -

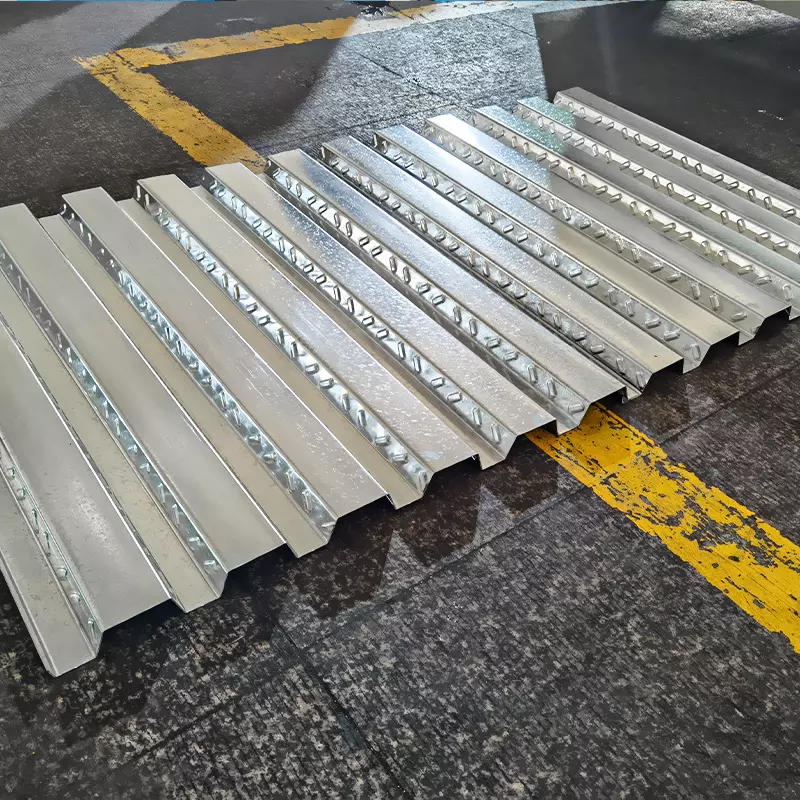

Trapezoidal Panel Roll Forming Machine

Trapezoidal Panel Roll Forming Machine -

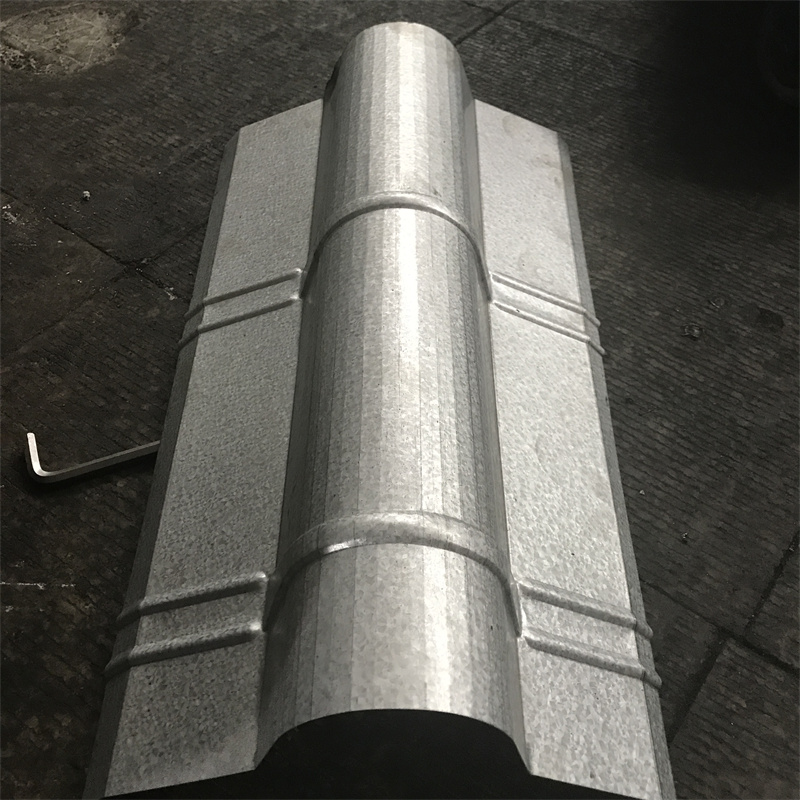

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine -

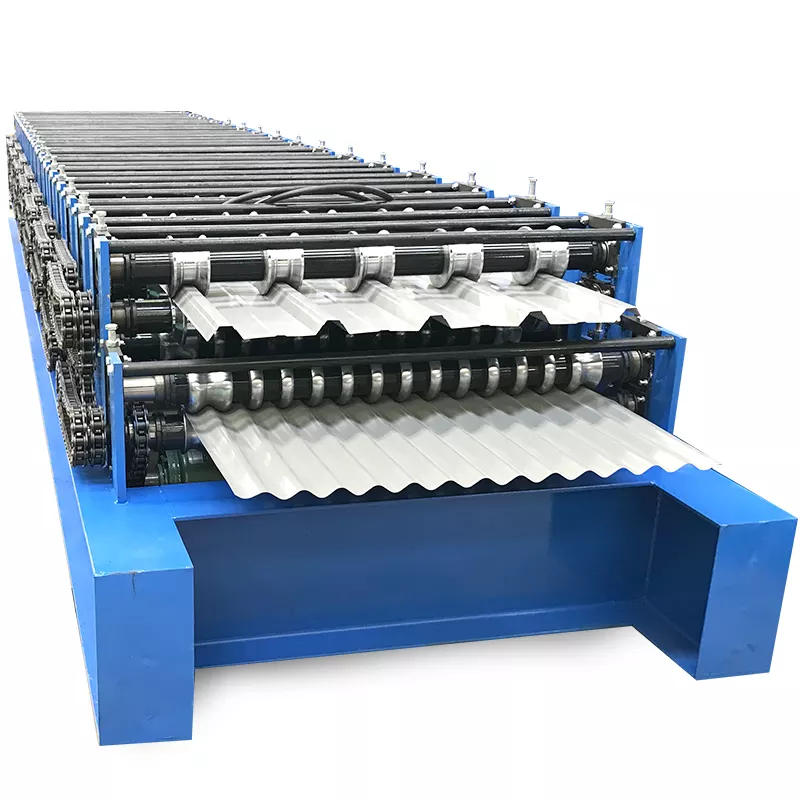

Double Layer Panel Roll Forming Machine

Double Layer Panel Roll Forming Machine

Different Types of Metal Roofing Tile Roll Forming Machines

There are a few different types of machines that can be used to create metal roofing tiles. The most common type is the roll forming machine. These machines use a series of dies to shape the metal into the desired tile shape.

Another type of machine that can be used is the press brake. This type of machine uses a large die to bend the metal into the desired shape.

Finally, there are laser cutters that can be used to create metal roofing tiles. These machines use a high-powered laser to cut the metal into the desired shape.

How to Choose the Best Metal Roofing Tile Roll Forming Machine for Your Project?

When choosing a metal roofing tile roll forming machine, there are several things to consider. First, you need to decide what type of metal roofing tile you want to use. There are many different types of metal roofing tiles on the market, so it is important to choose one that will work well with your project.

Second, you need to determine the size and shape of the metal roofing tiles you want to use. This will help you determine the best roll forming machine for your project.

Finally, you need to decide how much money you are willing to spend on a roll forming machine. With these factors in mind, you should be able to find the best roll forming machine for your project.

Conclusion

Metal roof tile roll forming machines are a great investment for any business that works with metal roofing. These machines make it easy to produce high-quality, long-lasting metal roofs quickly and efficiently. We hope this complete guide to buying a metal roofing tile roll forming machine has helped you learn what features to look for in the best machine for your needs, as well as how to get the best deal on one. With the right machine, you can take your business’s productivity and profits to a whole new level!

FAQ

What is roll forming used for?

Roll forming is a cost effective process for shaping metal coils into custom designed profiles. It is used by several industries to produce components for automobiles and appliances to aircraft and construction industries.