Gutter Roll Forming Machine is a very useful and efficient tool that can help you with metal roll forming. It is a computer-controlled machine that uses a set of rollers to form the metal into various shapes and sizes according to your specifications. This article will discuss how this machine works and the advantages it brings in terms of cost, efficiency, accuracy, and more!

What is Gutter Roll Forming Machine?

A gutter roll forming machine is a device that helps in the manufacturing of gutters. These machines are very helpful as they help in increasing the productivity and efficiency of the manufacturing process.

This machine offer many benefits over traditional methods of manufacturing gutters. They are faster, more efficient, and produce a better product. Gutter roll forming machines are faster than traditional methods because they use a continuous production process.

Benefits of Gutter Roll Forming Machines

There are many benefits of using a gutter roll forming machine and some of them are listed below:

- Increased productivity: The biggest advantage of using a gutter roll forming machine is that it helps in increasing the productivity of the manufacturing process. This is because the machine helps in reducing the time taken for each production cycle.

- Improved quality: Another benefit of using a gutter roll forming machine is that it helps in improving the quality of the gutters. This is because the machine ensures that each gutter is made with precision and accuracy.

- Reduced cost: One of the main advantages of using a gutter roll forming machine is that it helps in reducing the overall cost of production. This is because the machine helps in eliminating various wastages and errors during the manufacturing process.

- Environment-friendly: Another advantage of using a gutter roll forming machine is that it helps in making the production process more environment-friendly. This is because these machines help in reducing various emissions and pollutants during the manufacturing process.

How Does Gutter Roll Forming Machine Work?

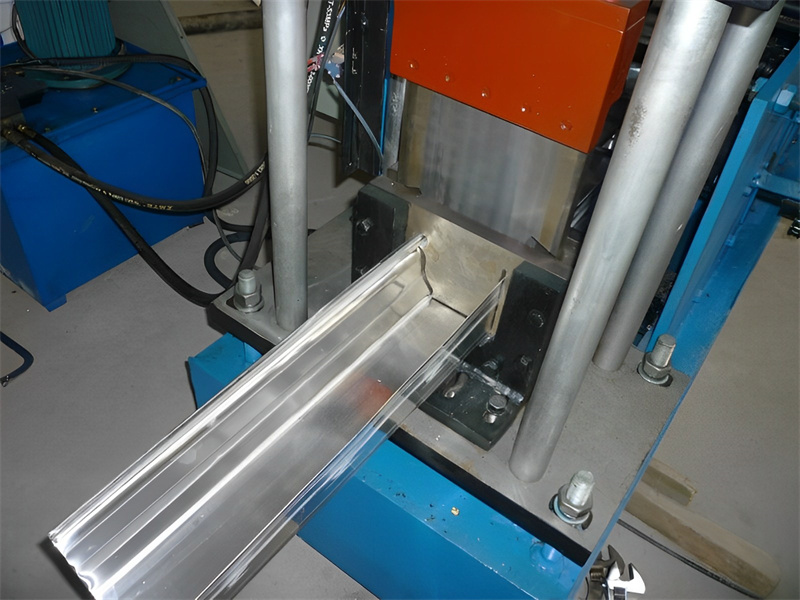

A gutter roll forming machine is a type of metalworking machine that is used to create gutters. The process of creating a gutter with a roll forming machine is simple. First, a coil of metal is fed into the machine. The machine then forms the metal into the shape of a gutter. Finally, the gutter is cut to length and then installed on a building.

There are many benefits to using a roll forming machine to create gutters. One benefit is that it is very fast. Another benefit is that it can create gutters in any size or shape. Additionally, roll forming machines are very versatile and can be used to create other types of metal products such as roofing panels and siding panels.

Common Uses of Gutter Roll Forming Machines

Gutter roll forming machines are commonly used in the construction and roofing industries. They are used to create gutters of various sizes and shapes. These machines can be used to create gutters made from different materials, including aluminum, steel, and vinyl.

Gutter roll forming machines are also commonly used to create downspouts. Downspouts are the pipes that carry water from the gutters to the ground. These machines can be used to create downspouts made from different materials, including aluminum, steel, and vinyl.

Gutter roll forming machines can also be used to create flashing. Flashing is a material that is placed around joints and seams in order to prevent water infiltration. These machines can be used to create flashing made from different materials, including aluminum, steel, and vinyl.

What to Look for When Purchasing a Gutter Roll Forming Machine?

There are a few things you should keep in mind when purchasing a gutter roll forming machine. First, you need to decide what type of gutter system you want to install. There are two types of gutters: seamless and sectional. Seamless gutters are made from a single piece of aluminum or other metal, while sectional gutters are made from several pieces that fit together.

Second, you need to decide what size machine you need. The size of the machine will determine the width of the gutters it can produce. Most machines can produce gutters that are up to six inches wide.

Third, you need to decide on the material you want your gutters to be made from. Aluminum is the most popular choice for gutters because it is durable and does not rust. Other materials, such as vinyl and steel, are also available but may not be as durable as aluminum.

Finally, you need to decide whether you want a manual or automatic gutter roll forming machine. Manual machines require someone to operate them, while automatic machines can be operated by one person with the push of a button.

Conclusion

Gutter roll forming machines are an extremely useful tool for any construction project. They allow you to easily and quickly create custom gutter shapes that can save time and money. With their automation capabilities, gutters can be formed with more accuracy than ever before. Additionally, the use of a gutter roll forming machine eliminates manual labor costs as well as reducing waste materials associated with traditional methods of producing gutters. Whether it is for residential or commercial applications, this type of machine has the potential to revolutionize how we build structures today.