If you work in the manufacturing industry, you may have heard the term “corrugated sheet roll forming” in conversations about production processes. Corrugated sheets are widely used in roofing, siding, and industrial manufacturing applications due to their strength, durability, and versatility. But how exactly are these sheets manufactured? In this post, we’ll provide an overview of the mechanics of width corrugated sheet roll forming machines, explaining how they work, their advantages, applications, and maintenance. By the end of this post, you’ll have a better understanding of width corrugated sheet roll forming and how it can benefit your business.

what is Corrugated Sheet Roll Forming?

Corrugated sheet roll forming is a manufacturing process used to create corrugated sheets, which are widely used in roofing, siding, and industrial manufacturing applications. Corrugated sheets are sheets of metal that have been shaped with ridges and valleys, which increase their strength and durability.

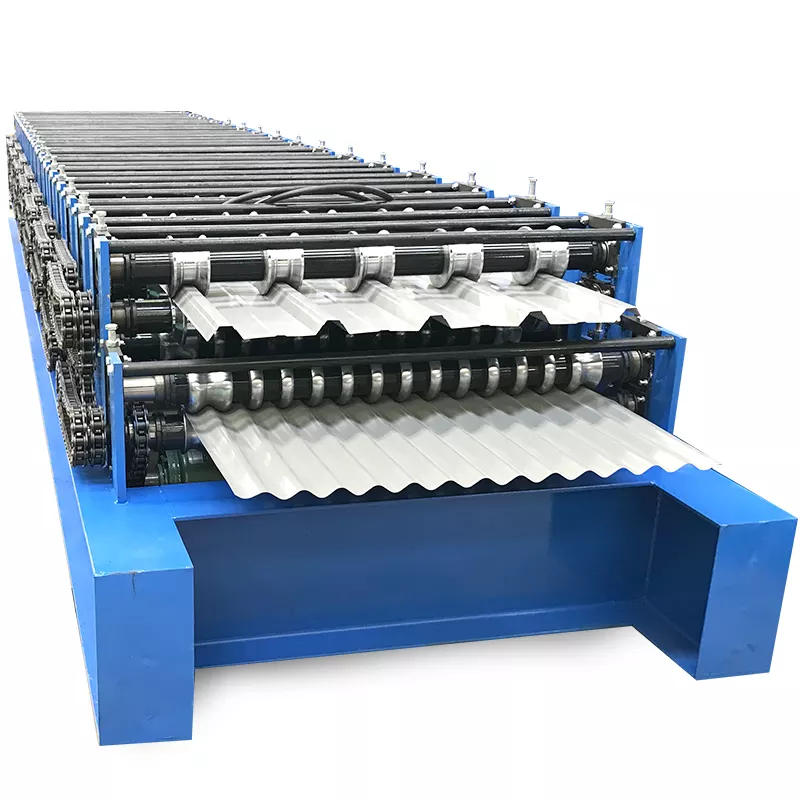

Roll forming is the process of continuously bending and shaping a metal strip or sheet into a desired shape using a series of rollers. In corrugated sheet roll forming, the metal sheet is fed through a series of rollers that gradually shape it into the corrugated pattern.

The rollers can be adjusted to create different shapes and sizes of corrugated sheets, and the machine can be customized to meet specific production needs. Corrugated sheet roll forming offers several advantages over other manufacturing methods, including cost-effectiveness, precision, and efficiency.

By understanding the basics of corrugated sheet roll forming, businesses can better understand how this manufacturing process works and make informed decisions when it comes to investing in corrugated sheet roll forming machines for their production needs.

Components of Width Corrugated Sheet Roll Forming Machine

-

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Cable Ladder Roll Forming Machine

Cable Ladder Roll Forming Machine -

PV Mounting Bracket C Shape Profile Roll Forming Machine

PV Mounting Bracket C Shape Profile Roll Forming Machine -

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine -

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile)

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile) -

PV Mounting Bracket Z Shape Profile Roll Forming Machine

PV Mounting Bracket Z Shape Profile Roll Forming Machine -

Solar mounting strut channel roll forming machine

Solar mounting strut channel roll forming machine -

Strut Channel Roll Forming Machine

Strut Channel Roll Forming Machine

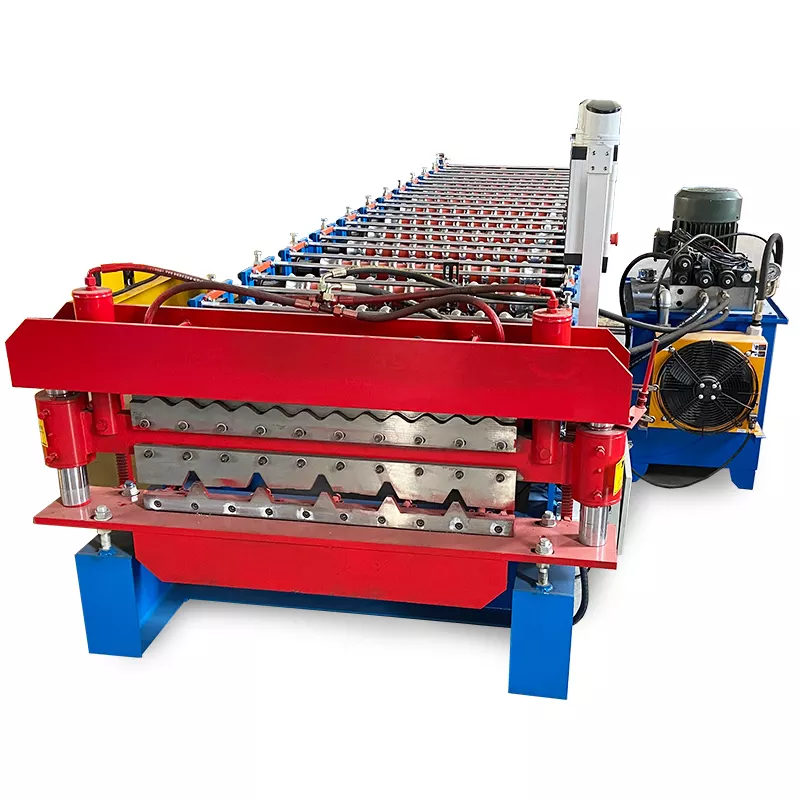

Width corrugated sheet roll forming machines consist of several components that work together to create corrugated sheets of metal. Here are the different components of a typical width corrugated sheet roll forming machine:

- Decoiler: The decoiler is a component that holds the metal coil and feeds it into the roll forming machine. The decoiler can be manual or automatic and can handle different widths and thicknesses of metal.

- Leveling Unit: The leveling unit is a component that flattens and straightens the metal strip before it enters the roll forming machine. This ensures that the metal is evenly fed into the machine, improving the accuracy and consistency of the final product.

- Punching Unit: The punching unit is a component that punches holes or shapes into the metal strip as it enters the roll former. This allows for the creation of corrugated sheets with customized hole patterns, which is important for attaching them to other building components.

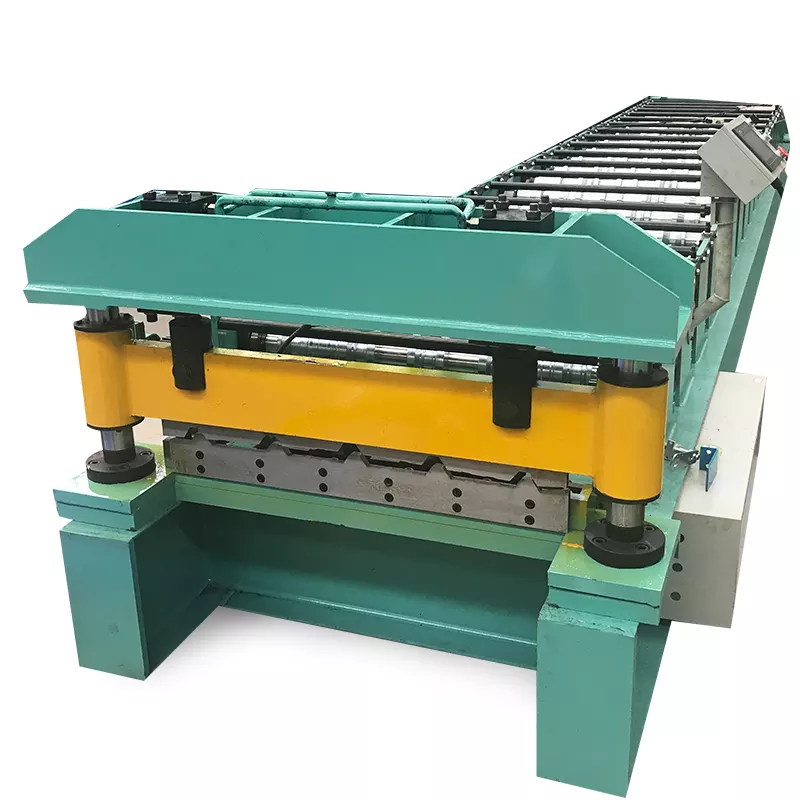

- Roll Former: The roll former is the heart of the width corrugated sheet roll forming machine. It consists of a series of rollers that gradually shape the metal strip into the desired corrugated pattern. The rollers can be adjusted to create different shapes and sizes of corrugated sheets, and the machine can be customized to meet specific production needs.

- Cutting System: The cutting system is a component that cuts the finished corrugated sheet to the desired length. This can be done using a variety of methods, such as hydraulic shearing or sawing.

- Control Panel: The control panel is a component that allows operators to control and monitor the width corrugated sheet roll forming machine. It includes a range of features such as digital readouts, control knobs, and emergency stop buttons that allow operators to adjust the machine’s settings and respond quickly to any issues that arise.

By understanding the different components of a width corrugated sheet roll forming machine, businesses can better understand how these machines work and make informed decisions when it comes to purchasing, maintaining, and operating them.

Working Principle of Width Corrugated Sheet Roll Forming Machine

The working principle of width corrugated sheet roll forming machines is relatively simple, but it involves a series of precise steps to create corrugated sheets with a consistent shape and size. Here are the basic steps involved in the working principle of width corrugated sheet roll forming machines:

- Decoiling: The metal strip is uncoiled from a coil and fed into the roll forming machine.

- Leveling: The leveling unit straightens the metal strip, ensuring that it is even and flat as it enters the roll forming machine.

- Punching: The punching unit creates holes or shapes in the metal strip to meet specific design requirements.

- Roll Forming: The metal strip is gradually shaped into the desired corrugated pattern by a series of rollers. The rollers can be adjusted to create different shapes and sizes of corrugated sheets.

- Cutting: Once the metal strip has been shaped into corrugated sheets, the cutting system cuts the sheets to the desired length.

- Stacking: The finished corrugated sheets are stacked and ready for use.

The working principle of width corrugated sheet roll forming machines is highly precise and requires skilled operators to ensure the quality of the final product. By understanding the working principle of width corrugated sheet roll forming machines, businesses can better understand how these machines work and make informed decisions when it comes to investing in them for their production needs.

Advantages of Width Corrugated Sheet Roll Forming Machine

Using width corrugated sheet roll forming machines has several advantages over other manufacturing methods. Here are some of the advantages of using width corrugated sheet roll forming machines:

- High Production Speed: Width corrugated sheet roll forming machines can produce corrugated sheets at a high rate of speed, which allows for large quantities to be produced quickly and efficiently.

- Cost-Effectiveness: Width corrugated sheet roll forming machines are highly cost-effective when compared to other manufacturing methods. The machines are designed to operate continuously, with minimal downtime, which reduces the overall cost of production.

- Precision: Width corrugated sheet roll forming machines are highly precise and can produce corrugated sheets with consistent quality and accuracy. This is important for industries that require high-quality products with specific measurements and dimensions.

- Customization: Width corrugated sheet roll forming machines can be customized to meet specific production requirements, such as the size and shape of the corrugated sheet, the thickness and type of metal, and the hole patterns required.

- Minimal Material Waste: Width corrugated sheet roll forming machines produce very little material waste, which helps to minimize the overall cost of production and is better for the environment.

Overall, using width corrugated sheet roll forming machines offers several advantages over other manufacturing methods, making them a popular choice in industries such as construction, roofing, and industrial manufacturing.

In summary, width corrugated sheet roll forming machines offer several advantages over other manufacturing methods, including high production speed, cost-effectiveness, precision, customization, and minimal material waste. By understanding the mechanics and components of width corrugated sheet roll forming machines, businesses can make informed decisions when it comes to purchasing, maintaining, and operating these machines. With their ability to produce corrugated sheets quickly, accurately, and with consistent quality, width corrugated sheet roll forming machines are an essential tool for industries that require high-quality, durable, and reliable corrugated sheets.

Frequently Asked Questions (FAQ)

1) What coil width ranges do corrugated sheet roll forming machines support?

- Common effective widths are 650–1,250 mm with 914, 1,000, and 1,200 mm popular. Raw coil width is typically 762–1,250 mm depending on profile pitch and side trims. Always confirm “feeding width” vs “effective cover width.”

2) What tolerances are realistic for cut length and corrugation pitch?

- For roofing-grade lines: cut length ±1.0–1.5 mm at up to 40–60 m/min; corrugation pitch ±0.5 mm with properly aligned stands and quality tooling. Higher speeds or thinner coils may require servo shear and laser encoder feedback to maintain accuracy.

3) Which materials and thicknesses run best on corrugated sheet roll formers?

- GI, GL, PPGI/PPGL, aluminum, and sometimes 304 stainless. Typical thickness: 0.25–0.8 mm for building envelopes; 0.9–1.2 mm possible with higher motor power and pass design adjustments. Pre-painted coils benefit from polyurethane or hard-chrome-coated rolls.

4) How do I minimize oil canning and edge waviness on wide corrugated profiles?

- Ensure proper entry leveling, balanced flower design, pass progression that avoids overbending, consistent coil tension, and crowned rolls where needed. Use automatic gap adjustment and periodic roll regrinding. Verify panel flatness with inline straightness checks.

5) What maintenance intervals keep uptime high?

- Daily: clean roll surfaces, check debris near shear, verify lubrication. Weekly: inspect bearings, chain tension, encoder couplings. Quarterly: align roll stands, verify pass gaps with feeler gauges, check shear blades for burrs. Annually: full geometric alignment, electrical cabinet thermal scan, and roll re-polishing as needed.

2025 Industry Trends for Corrugated Sheet Roll Forming Machines

- Servo-driven shears and encoders become standard on wide lines to hold ±1 mm accuracy at higher speeds.

- Inline vision systems detect paint defects, micro-scratches, and pitch drift on PPGI/PPGL.

- Quick-change cassette tooling reduces changeovers for multiple corrugation pitches and cover widths.

- Sustainability KPIs: energy use (kWh/ton) and scrap rate are reported in buyer audits.

- Digital work instructions and recipe management standardize set-ups for varied coil grades and coatings.

2025 Benchmarks and Adoption Snapshot

| KPI | 2023 Typical Value | 2025 Best-in-Class | Why It Matters | Source |

|---|---|---|---|---|

| Changeover time (profile cassette) | 25–40 min | 8–15 min | Higher OEE for multi-SKU roofing | Vendor demos at Wire & Tube/CIIF; OEM datasheets |

| Cut-length accuracy at 50 m/min | ±1.5 mm | ±0.8–1.0 mm | Lower rework and waste | EN 1090 shop practices; OEM specs |

| Scrap rate on PPGI coils | 2.0–3.5% | 0.8–1.5% | Paint quality and cost savings | Coater QC notes; inline vision case notes |

| Energy intensity (kWh/ton) | 150–190 | 110–145 | Lower OpEx, ESG alignment | ABB/Siemens efficiency guides |

| Inline vision/laser QA adoption | ~20–30% | 45–60% | Real-time defect detection | Keyence/Micro-Epsilon app notes |

| Typical speed (roofing profiles) | 25–45 m/min | 50–80 m/min | Throughput without losing tolerance | OEM brochures and field reports |

Authoritative resources for verification:

- ISO 9001 and ISO 12100: https://www.iso.org

- IEC 60204-1 Electrical safety: https://webstore.iec.ch

- EU CE Machinery Regulation info: https://ec.europa.eu

- ABB Drives energy optimization: https://new.abb.com/drives

- Siemens motion control energy efficiency: https://new.siemens.com

- Keyence inline inspection: https://www.keyence.com

Latest Research Cases

Case Study 1: Reducing Pitch Variation on 1,200 mm Effective Width Corrugated Panels (2025)

Background: A roofing manufacturer running PPGL coils at 0.5–0.6 mm thickness experienced pitch drift and edge waviness at speeds above 40 m/min.

Solution: Implemented servo gap control across critical passes, upgraded to a 7-roller precision leveller, and added inline laser pitch measurement with closed-loop correction.

Results: Pitch variation reduced from ±0.9 mm to ±0.35 mm; usable yield improved by 1.7%; stable operation at 60 m/min with no visible oil canning on wide panels.

Case Study 2: Scrap Reduction on Pre-Painted Corrugated Sheet Roll Forming (2024)

Background: High scrap (3.1%) due to paint micro-scratches and shear burrs on 914 mm cover width profiles.

Solution: Switched to polyurethane top rolls for sensitive surfaces, introduced non-contact strip guides at entry, re-honed flying shear blades, and added camera-based defect flagging.

Results: Scrap dropped to 1.2%; customer returns decreased by 35%; cut edge burr height reduced by 42% leading to faster on-site installation.

Expert Opinions

- Dr. Lin Qiu, Associate Professor, Advanced Manufacturing, Shanghai Jiao Tong University

“Wide corrugated profiles magnify setup errors. Closed-loop pass-gap control and better entry leveling are the fastest levers to stabilize pitch and minimize waviness.” - Marco Santori, Technical Director, Roofing Systems Integrator (EU)

“On pre-painted coils, surface protection is a process, not a product. Polyurethane rolls, non-contact guides, and disciplined coil handling cut most cosmetic defects before they become scrap.” - Priya Natarajan, Plant Manager, Building Envelope Fabricator (India)

“Recipe management plus cassette tooling beat raw line speed for profitability. We routinely change between 762 and 1,200 mm cover widths in under 12 minutes.”

Practical Tools/Resources

- Roll design and simulation

- UBECO PROFIL: https://www.ubeco.com

- COPRA RF: https://www.datam.de

- Altair Inspire/Form: https://www.altair.com

- Standards and compliance for corrugated sheet roll forming lines

- ISO 12100 Risk Assessment: https://www.iso.org

- IEC 60204-1 Electrical Safety: https://webstore.iec.ch

- CE Machinery Regulation guidance: https://ec.europa.eu

- Quality and inline inspection

- Keyence vision/laser sensors: https://www.keyence.com

- Micro‑Epsilon displacement measurement: https://www.micro-epsilon.com

- Maintenance and OEE tracking

- UpKeep CMMS: https://www.onupkeep.com

- Fiix CMMS: https://www.fiixsoftware.com

Implementation tip: Specify acceptance criteria in FAT for wide corrugated lines—cut length ±1.0 mm at target speed, pitch tolerance ±0.5 mm, max edge waviness ≤2 mm per 1,000 mm, cosmetic defect threshold by AQL, and energy intensity target (kWh/ton) recorded during test runs.

Last updated: 2025-10-23

Changelog: Added 5 targeted FAQs, 2025 market benchmarks table with sources, two recent case studies, expert viewpoints, and actionable tools/resources with FAT implementation tip.

Next review date & triggers: 2026-05-20 or earlier if new CE Machinery Regulation guidance, major OEM releases on servo gap control/cassette tooling, or updated energy/scrap benchmarks are published.