In today’s high-tech world, monitoring equipment is essential in industries ranging from telecommunications to energy management. The demand for precision-engineered enclosures, frames, and panels that house this equipment is rising, and Monitoring Equipment Roll Forming Machines are stepping up to the challenge. These machines streamline the production of high-quality metal components, ensuring the durability, accuracy, and scalability that modern monitoring systems require.

In this article, we’ll explore the applications, features, pricing, safety standards, and technological innovations of these machines, and why Wuxi Sunway Machinery is a trusted name in delivering top-tier roll-forming solutions. If you’re a manufacturer of monitoring equipment or related infrastructure, this guide will provide actionable insights into the benefits of investing in a roll-forming solution tailored for monitoring equipment.

What Are Monitoring Equipment Roll Forming Machines?

A Monitoring Equipment Roll Forming Machine is specialized machinery designed to produce metal frames, enclosures, brackets, and panels for housing monitoring systems. These systems include servers, telecommunications equipment, energy meters, control panels, and more. The machines operate by feeding metal sheets or coils into a series of rollers, gradually shaping the material into the desired profile with precision and consistency.

Key Features

- Precision Engineering: Ensures profiles meet exact specifications for compatibility with monitoring equipment.

- Customizable Tooling: Supports the production of unique designs tailored to specific monitoring systems.

- High-Speed Production: Capable of delivering large quantities without compromising quality.

- Compatibility with Smart Materials: Processes materials like aluminum, stainless steel, and pre-coated metals.

- Eco-Friendly Practices: Reduces waste and supports the use of recyclable materials.

Applications of Monitoring Equipment Roll Forming Machines

These machines are critical to manufacturing components for monitoring systems used in diverse industries. Here are the key applications where they shine:

1. Telecommunications Infrastructure

- Use Case: Producing enclosures and frames for telecom towers, base stations, and server racks.

- Why It’s Essential: Ensures durable, weather-resistant components capable of withstanding environmental challenges.

2. Energy Management Systems

- Use Case: Manufacturing panels and frames for energy meters, solar panel mounts, and smart grid infrastructure.

- Why It’s Critical: Provides precision components that ensure the accuracy and reliability of energy monitoring systems.

3. Industrial Automation

- Use Case: Creating cabinets and enclosures for PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems.

- Why It’s Valuable: Protects sensitive equipment in harsh industrial environments.

4. Building Management Systems (BMS)

- Use Case: Producing control panels and metal components for HVAC (Heating, Ventilation, and Air Conditioning) and security systems.

- Why It’s Relevant: Ensures compatibility with smart building technologies and IoT-enabled systems.

5. Renewable Energy Monitoring

- Use Case: Crafting supports, brackets, and frames for wind turbines, solar inverters, and battery storage systems.

- Why It’s Beneficial: Enables the efficient monitoring and management of renewable energy systems.

6. Transportation Systems

- Use Case: Manufacturing components for traffic monitoring, railway signaling, and airport control systems.

- Why It’s Unique: Provides durable, weather-resistant components for outdoor monitoring solutions.

Key Features of Wuxi Sunway Monitoring Equipment Roll Forming Machines

When it comes to roll-forming solutions for monitoring equipment, Wuxi Sunway Machinery is a leader in innovation and reliability. Here’s what makes their machines stand out:

1. Modular Tooling Systems

- What It Offers: Interchangeable tooling for producing a variety of profiles on a single machine.

- Why It’s Essential:

- Reduces downtime during tooling changes.

- Supports custom designs for unique monitoring equipment applications.

2. High Precision and Accuracy

- Performance: Achieves tolerances as low as ±0.02mm, ensuring exact dimensions.

- Why It’s Important:

- Guarantees seamless integration with monitoring equipment.

- Reduces rework and material waste.

3. Advanced Material Handling

- Supported Materials:

- Galvanized Steel

- Stainless Steel

- Aluminum

- Pre-Coated Metals

- Why It’s Beneficial:

- Ensures compatibility with materials that offer durability and corrosion resistance.

- Supports lightweight designs for modern monitoring equipment.

4. IoT Integration

- What It Enables:

- Real-time monitoring of machine performance and production data.

- Predictive maintenance alerts to prevent downtime.

- Why It’s Revolutionary:

- Enhances production efficiency and reduces operational costs.

- Aligns with Industry 4.0 standards.

5. High-Speed Operation

- Performance: Produces up to 30–80 meters of profiles per minute, depending on the material and design complexity.

- Why It’s Necessary:

- Meets the high-volume demands of large-scale monitoring system projects.

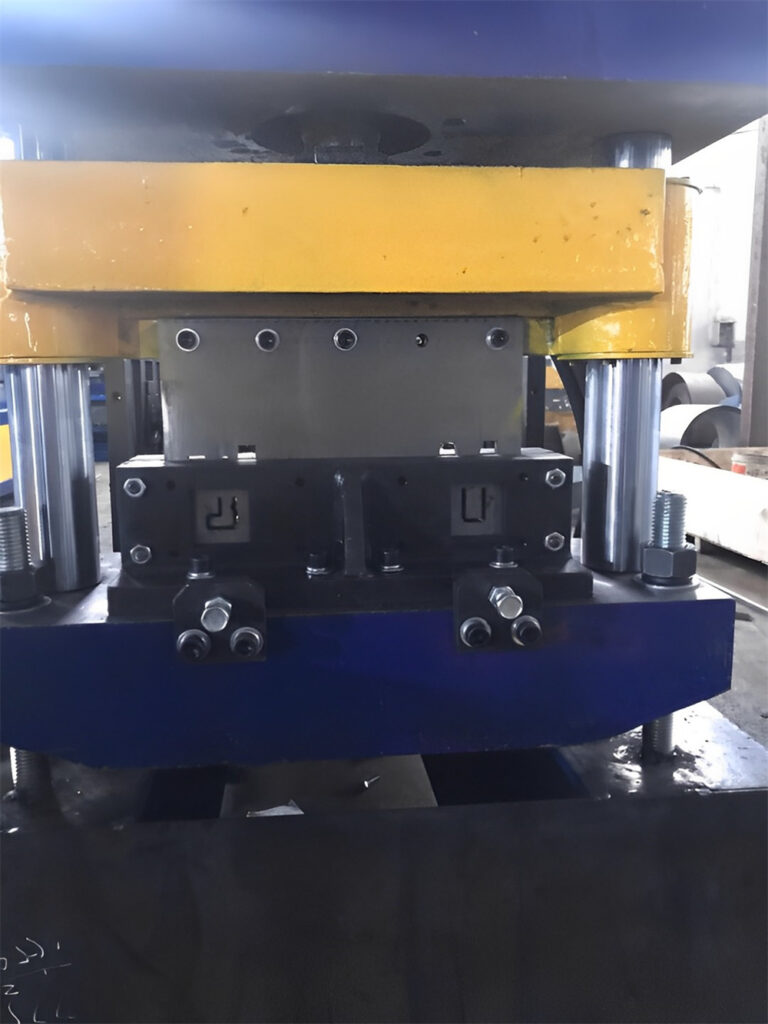

6. Integrated Cutting and Punching

- The Feature: Precision cutting and hole-punching capabilities integrated into the roll-forming process.

- Why It’s Game-Changing:

- Eliminates the need for post-production machining.

- Speeds up the delivery of ready-to-assemble components.

7. Noise and Vibration Reduction

- What It Includes: Advanced engineering to minimize noise and vibrations during operation.

- Why It’s Valuable:

- Creates a safer and more comfortable working environment.

- Reduces wear and tear on machine components.

Innovations in Monitoring Equipment Roll Forming Technology

The roll-forming industry is constantly evolving, with new technologies enhancing efficiency, precision, and sustainability. Here are some of the most exciting innovations in Monitoring Equipment Roll Forming Machines:

1. AI-Powered Quality Control

- What It Does: Uses artificial intelligence to analyze production data and detect defects in real time.

- Why It’s Revolutionary:

- Improves product quality by identifying issues early.

- Reduces waste and rework.

2. Digital Twin Technology

- What It Simulates: Virtual models of the machine and production process to optimize settings before actual production.

- Why It’s Useful:

- Reduces setup time and trial-and-error adjustments.

- Ensures consistent quality from the first run.

3. Multi-Profile Capability

- What It Enables: Produces multiple profiles simultaneously, increasing production speed and versatility.

- Why It’s Beneficial:

- Supports complex monitoring equipment designs.

- Reduces production timelines for large projects.

4. Eco-Friendly Coating Applications

- What It Includes: Systems for applying protective or decorative coatings during the roll-forming process.

- Why It’s Critical:

- Enhances the durability and aesthetics of metal components.

- Aligns with the industry’s push for sustainable manufacturing.

5. Smart Maintenance Systems

- What It Provides: Predictive maintenance alerts based on IoT data and machine learning algorithms.

- Why It’s Effective:

- Prevents unplanned downtime.

- Extends the lifespan of the machine.

Pricing of Monitoring Equipment Roll Forming Machines

The cost of a Monitoring Equipment Roll Forming Machine depends on its features, capacity, and customization level. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Standard Machines | Basic roll-forming for monitoring equipment | 150,000–150,000–150,000–400,000 |

| Advanced Machines | High-speed, integrated cutting and punching systems | 400,000–400,000–400,000–1,000,000 |

| Fully Customizable Machines | IoT, modular tooling, and multi-profile capabilities | 1,000,000–1,000,000–1,000,000–2,500,000 |

For detailed pricing and financing options, contact Wuxi Sunway Machinery.

Why Choose Wuxi Sunway Machinery for Monitoring Equipment Roll Forming Machines?

Wuxi Sunway Machinery is a global leader in roll-forming technology, offering unparalleled solutions for manufacturers of monitoring equipment. Here’s why they’re trusted by clients worldwide:

- Proven Expertise: Decades of experience in designing and delivering high-performance roll-forming machines.

- Global Reach: Machines operating successfully across Asia, Europe, the Americas, and beyond.

- Innovation-Driven: Features like IoT integration, AI-powered quality control, and modular tooling set their machines apart.

- Sustainability Commitment: Machines optimized for energy efficiency and eco-friendly production.

- Comprehensive Support: From initial consultation to installation and after-sales service, Wuxi Sunway ensures a seamless experience.

FAQs About Monitoring Equipment Roll Forming Machines

| Question | Answer |

|---|---|

| What materials can these machines process? | Galvanized steel, stainless steel, aluminum, and pre-coated metals. |

| What is the production speed of these machines? | Up to 30–80 meters per minute, depending on material and profile complexity. |

| Can these machines handle custom designs? | Yes, modular tooling supports bespoke profiles for unique monitoring systems. |

| Do these machines include safety features? | Yes, they come with emergency stops, safety guards, and noise reduction systems. |

| Are these machines eco-friendly? | Yes, they feature energy-efficient motors and reduce material waste. |

| What industries benefit from these machines? | Telecommunications, energy management, industrial automation, and transportation systems. |

| What is the typical warranty period? | Machines usually come with a 1–2 year warranty, with extended options available. |

| Can these machines work with IoT systems? | Absolutely! IoT integration enables real-time monitoring and predictive maintenance. |

| What is the price range for these machines? | Prices range from 150,000to150,000 to 150,000to2,500,000, depending on features and customization options. |

Real-World Case Studies: Monitoring Equipment Roll Forming Machines in Action

The versatility and efficiency of Monitoring Equipment Roll Forming Machines have transformed manufacturing processes across various industries. Here are some real-world success stories that demonstrate their impact:

1. Case Study: Telecommunications Equipment Manufacturer

- Client: A global leader in producing infrastructure for 5G networks.

- Challenge: The company needed a roll-forming machine capable of producing lightweight yet durable enclosures for telecommunications towers.

- Solution: Wuxi Sunway Machinery provided a custom roll-forming machine with integrated cutting and punching capabilities.

- Results:

- Reduced production time by 40%, enabling faster delivery to clients.

- Enhanced product quality with precise tolerances, ensuring compatibility with 5G equipment.

- Decreased material waste by 15%, aligning with the company’s sustainability goals.

2. Case Study: Energy Management System Provider

- Client: A manufacturer of smart meters and energy monitoring panels in Europe.

- Challenge: The company required modular tooling to produce various panel designs for different applications.

- Solution: Wuxi Sunway delivered a roll-forming machine with interchangeable tooling systems.

- Results:

- Increased production flexibility, allowing the company to cater to diverse customer needs.

- Reduced downtime during tooling changes by 50%.

- Enabled the use of recyclable materials, supporting environmentally friendly production practices.

3. Case Study: Industrial Automation Supplier

- Client: A supplier of enclosures for PLCs and SCADA systems in North America.

- Challenge: The company needed enclosures that could withstand extreme industrial conditions, including high temperatures and humidity.

- Solution: Wuxi Sunway provided a roll-forming machine capable of processing stainless steel and aluminum with advanced surface finishes.

- Results:

- Produced corrosion-resistant enclosures, extending product lifespan.

- Achieved consistent quality across large production runs, meeting strict industry standards.

- Reduced operating costs by optimizing material usage.

4. Case Study: Renewable Energy Monitoring Systems

- Client: A company specializing in monitoring systems for solar farms and wind turbines.

- Challenge: The client needed lightweight, weather-resistant frames for outdoor applications.

- Solution: Wuxi Sunway designed a machine that processed aluminum and pre-coated metals for enhanced durability.

- Results:

- Increased production efficiency by 30%.

- Delivered frames that met international standards for renewable energy equipment.

- Strengthened the company’s position as a leading supplier in the renewable energy sector.

Global Market Trends for Monitoring Equipment Roll Forming Machines in 2025

As industries worldwide embrace smart technology and automation, the demand for monitoring equipment components is evolving. Here are the key market trends driving the growth of Monitoring Equipment Roll Forming Machines:

1. Surge in IoT Adoption

- Trend: The integration of IoT devices in industries such as telecommunications, energy, and manufacturing is driving the need for precise and reliable enclosures.

- Impact on Machines:

- Machines must produce components with tight tolerances to house sensitive electronic equipment.

- IoT-enabled roll-forming machines are becoming essential for real-time production monitoring.

2. Focus on Sustainability

- Trend: Governments and businesses are prioritizing sustainable manufacturing practices to reduce environmental impact.

- Impact on Machines:

- Machines must support the use of recyclable materials like aluminum and pre-coated steel.

- Energy-efficient motors and workflows are becoming standard features.

3. Increased Demand for Modular Systems

- Trend: Modular and customizable systems are becoming popular in industries like energy management and industrial automation.

- Impact on Machines:

- Roll-forming machines must offer modular tooling to produce diverse profiles on a single production line.

- Flexibility is a key selling point for manufacturers catering to dynamic market needs.

4. Expansion of 5G Networks

- Trend: The global rollout of 5G networks is driving demand for telecommunications infrastructure.

- Impact on Machines:

- Machines must produce lightweight, corrosion-resistant components for outdoor telecom installations.

- High-speed production capabilities are essential to meet tight project deadlines.

5. Growth in Renewable Energy Projects

- Trend: The renewable energy sector is expanding rapidly, requiring monitoring systems for solar farms, wind turbines, and battery storage units.

- Impact on Machines:

- Machines must produce durable, weather-resistant components for outdoor applications.

- Precision and quality are critical to ensuring the reliability of renewable energy systems.

Safety Standards for Monitoring Equipment Roll Forming Machines

Safety is a top priority in modern manufacturing, and Monitoring Equipment Roll Forming Machines are designed to meet stringent safety standards. Here are the key safety features and compliance measures:

1. CE Marking

- Region: Europe

- Requirement: Ensures machines meet EU safety, health, and environmental protection standards.

- Machine Feature: Wuxi Sunway machines comply with CE regulations, providing peace of mind for European manufacturers.

2. OSHA Compliance

- Region: USA

- Requirement: Protects workers from hazards in the workplace under the Occupational Safety and Health Administration.

- Machine Feature: Includes emergency stop systems, safety guards, and noise reduction technologies.

3. ISO 45001 Certification

- Region: Global

- Requirement: Occupational health and safety management systems.

- Machine Feature: Wuxi Sunway designs its machines to minimize operator risks through ergonomic controls and automated processes.

4. Light Curtains

- What It Does: Detects objects or personnel in hazardous zones and pauses machine operations automatically.

- Why It’s Critical: Prevents accidents without interrupting production workflows.

5. Safety Guards and Interlocks

- What It Includes: Protective barriers around moving parts and interlock systems that prevent the machine from operating unless all guards are in place.

- Why It’s Effective: Reduces the risk of injuries caused by human error or mechanical malfunctions.

Sustainability Practices in Monitoring Equipment Manufacturing

As industries prioritize environmental responsibility, Monitoring Equipment Roll Forming Machines are adapting to support sustainable practices. Here’s how:

1. Energy Efficiency

- Feature: Energy-saving motors and optimized workflows reduce electricity consumption.

- Impact: Lower energy usage minimizes the carbon footprint of manufacturing operations.

2. Reduced Material Waste

- Feature: Precision cutting and forming systems minimize scrap during production.

- Impact: Reduces the need for raw materials, conserving natural resources.

3. Support for Recyclable Materials

- Feature: Machines are designed to process materials like aluminum, which can be recycled indefinitely.

- Impact: Promotes circular economy practices and reduces landfill waste.

4. Long-Lasting Components

- Feature: Durable components require less frequent replacement, reducing overall material consumption.

- Impact: Extends the lifecycle of monitoring equipment, reducing environmental impact.

FAQs About Monitoring Equipment Roll Forming Machines

| Question | Answer |

|---|---|

| Can these machines produce custom profiles? | Yes, Wuxi Sunway machines feature modular tooling for unique designs. |

| What materials can these machines process? | Galvanized steel, stainless steel, aluminum, and pre-coated metals. |

| Are these machines eco-friendly? | Yes, they include energy-efficient motors and reduce material waste. |

| Do these machines meet global safety standards? | Absolutely! They comply with CE, OSHA, and ISO 45001 certifications. |

| Are these machines suitable for high-volume production? | Yes, they can produce up to 80 meters of profiles per minute. |

| What is the warranty period for these machines? | Typically 1–2 years, with extended warranty options available. |

| Can these machines integrate with IoT systems? | Yes, IoT-enabled features allow real-time monitoring and predictive maintenance. |

| What industries benefit from these machines? | Telecommunications, energy management, industrial automation, and renewable energy sectors. |

| What is the price range of these machines? | Prices range from 150,000to150,000 to 150,000to2,500,000, depending on features and customization. |

Conclusion: Leading the Future of Monitoring Equipment Manufacturing

Monitoring Equipment Roll Forming Machines are shaping the future of precision and efficiency in manufacturing. With cutting-edge features, sustainability practices, and robust safety standards, these machines are essential for meeting the demands of a rapidly evolving market.

Ready to invest in the future of monitoring equipment production? Partner with Wuxi Sunway Machinery today and explore their state-of-the-art solutions. Together, let’s revolutionize manufacturing—one profile at a time.