In the ever-expanding network of global highways, safety is paramount. Highway guardrails play a critical role in protecting drivers and passengers, minimizing damage during collisions, and preventing vehicles from leaving the roadway. The production of these essential safety components relies on advanced Highway Guardrail Roll Forming Machines, which are designed to deliver precision-engineered guardrails that meet international safety standards.

These machines are at the forefront of modern manufacturing, enabling the production of durable, high-strength guardrails in various designs, such as W-beam, thrie-beam, and custom profiles. With their ability to process heavy-duty materials like galvanized steel, these machines ensure that guardrails are robust enough to withstand high-impact collisions while maintaining a sleek, uniform appearance for road aesthetics.

In this comprehensive guide, we’ll explore the applications, features, production process, pricing, technological advancements, and market trends of Highway Guardrail Roll Forming Machines. Additionally, we’ll highlight why Wuxi Sunway Machinery is a trusted name in the global roll-forming industry, providing cutting-edge solutions for manufacturers worldwide.

What is a Highway Guardrail Roll Forming Machine?

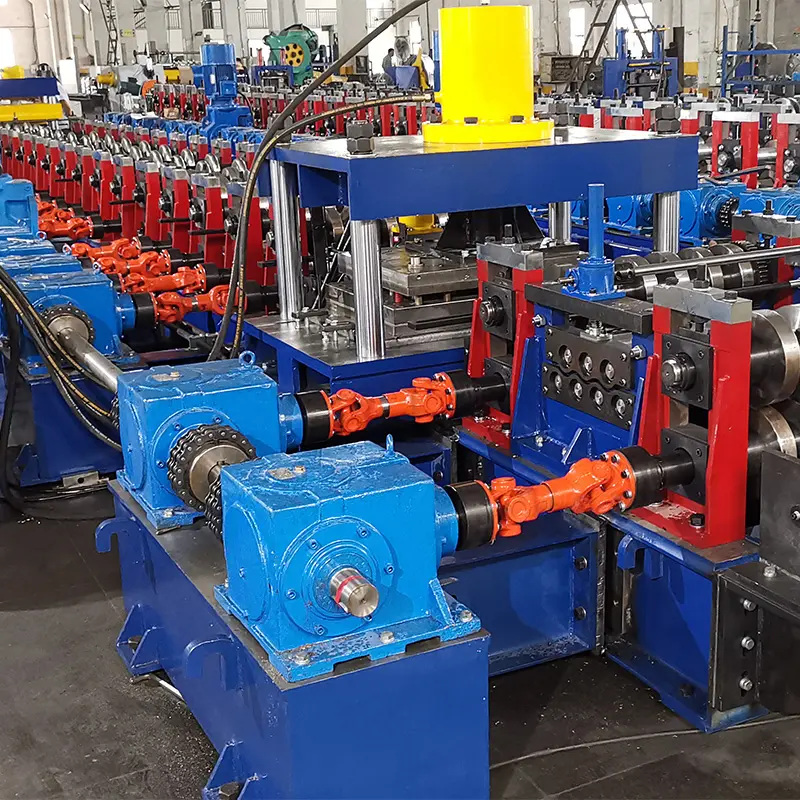

A Highway Guardrail Roll Forming Machine is an industrial system specifically designed to produce guardrail components used in road safety systems. These machines process raw materials, typically galvanized or stainless steel, through a series of rollers that shape the material into the desired guardrail profile.

The most common profiles produced by these machines include:

- W-Beam Guardrails: Standard two-wave guardrails commonly used on highways.

- Thrie-Beam Guardrails: Three-wave guardrails offering enhanced impact resistance for high-risk areas.

- Custom Guardrails: Tailored profiles designed for specific safety or aesthetic requirements.

Applications of Highway Guardrail Roll Forming Machines

Highway guardrails are indispensable for ensuring road safety. The components produced by these machines are used in various applications, including:

1. Highway Safety Barriers

- Use Case: Guardrails installed along highways to prevent vehicles from veering off the road.

- Why It Matters: Reduces the severity of accidents by absorbing and deflecting impact forces.

2. Bridge and Overpass Protection

- Use Case: Guardrails installed on bridges and overpasses to protect vehicles from falling off elevated roadways.

- Why It’s Crucial: Enhances safety in areas with high-risk drop-offs.

3. Median Barriers

- Use Case: Guardrails placed in highway medians to prevent head-on collisions between opposing traffic lanes.

- Why It’s Important: Reduces the likelihood of cross-median crashes, saving lives.

4. Roadside Safety Systems

- Use Case: Guardrails installed along curves, steep embankments, or roadside hazards like trees and poles.

- Why It’s Relevant: Provides a critical layer of protection in areas prone to accidents.

5. Parking and Industrial Areas

- Use Case: Guardrails used in parking lots or industrial zones to protect vehicles, pedestrians, and infrastructure.

- Why It’s Useful: Prevents damage to property and ensures the safety of workers and visitors.

6. Custom Safety Solutions

- Use Case: Specialized guardrails designed for unique environments, such as mountainous roads or coastal highways.

- Why It’s Exciting: Combines functionality with design to address specific safety and environmental challenges.

Key Features of Wuxi Sunway Highway Guardrail Roll Forming Machines

Wuxi Sunway Machinery is a global leader in roll-forming technology, offering machines tailored to the highway safety industry. Their Highway Guardrail Roll Forming Machines are engineered to deliver precision, efficiency, and durability. Here are the standout features:

1. Multi-Profile Production Capability

- What It Supports: Machines can produce W-beam, thrie-beam, and custom guardrail profiles.

- Why It’s Beneficial: Allows manufacturers to cater to diverse market needs with a single machine.

2. High Material Compatibility

- Supported Materials:

- Galvanized steel

- Stainless steel

- High-strength alloys

- Why It Matters: Ensures the production of robust, corrosion-resistant guardrails suitable for outdoor use.

3. Integrated Punching and Cutting

- What It Offers: Built-in systems for punching holes and cutting guardrails to length.

- Why It’s Essential:

- Reduces the need for secondary processes.

- Ensures precision and consistency across all components.

4. High-Speed Production

- Performance: Capable of producing up to 30–50 meters of guardrails per minute, depending on material and design complexity.

- Why It’s Relevant: Meets the high-volume demands of large infrastructure projects.

5. Customizable Tooling

- What It Allows: Quick-change tooling systems for creating custom guardrail profiles tailored to specific project requirements.

- Why It’s Critical: Supports flexibility for manufacturers serving diverse industries.

6. IoT and Automation Integration

- What It Provides: Real-time monitoring, data collection, and automated adjustments through IoT-enabled sensors.

- Why It’s Critical:

- Enhances production efficiency.

- Minimizes errors and reduces material waste.

- Enables predictive maintenance to avoid downtime.

7. Compliance with International Standards

- What It Ensures: Machines are designed to produce guardrails that meet global safety standards such as AASHTO M180 and EN 1317.

- Why It’s Important: Guarantees the safety and reliability of guardrails in critical applications.

Production Workflow of a Highway Guardrail Roll Forming Machine

The production process for highway guardrails is designed to deliver efficiency, scalability, and precision. Here’s an overview of the workflow:

1. Material Loading

- Raw metal coils are loaded onto the machine’s decoiler, which feeds the material into the rollers.

2. Leveling

- A leveling system ensures the material is flat and free of defects before entering the roll-forming section.

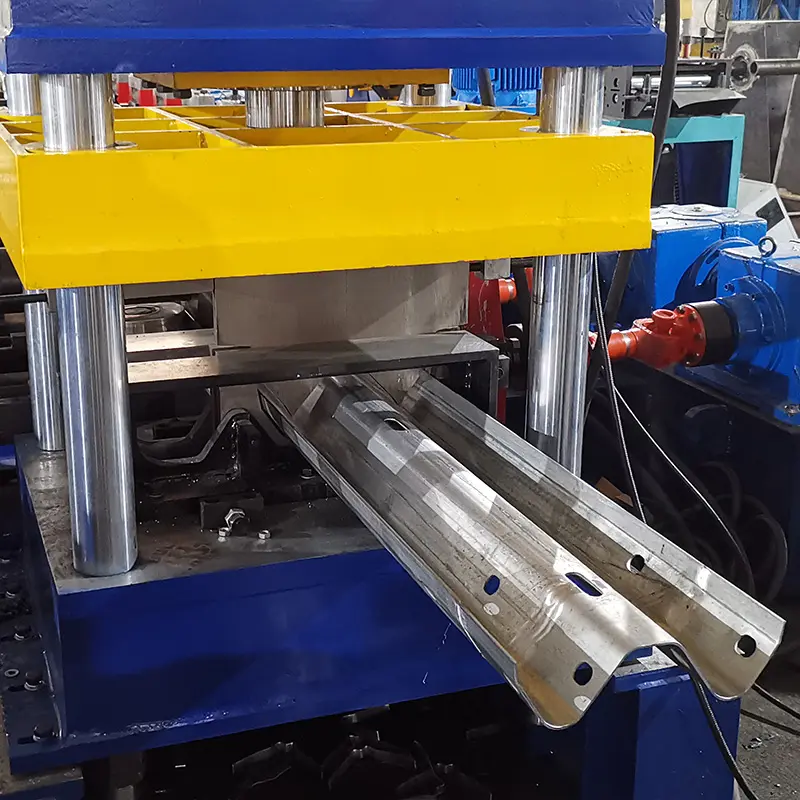

3. Roll Forming

- The material passes through a series of rollers that shape it into the desired guardrail profile incrementally.

4. Punching

- Integrated punching systems create holes or slots required for mounting the guardrails onto posts.

5. Cutting to Length

- Guardrails are cut to the required lengths with high precision using hydraulic or laser cutting systems.

6. Quality Inspection

- Each guardrail is inspected for dimensional accuracy and compliance with safety standards.

7. Stacking and Packaging

- Finished guardrails are stacked and prepared for transportation to installation sites.

Pricing of Highway Guardrail Roll Forming Machines

The cost of a Highway Guardrail Roll Forming Machine depends on its features, production capacity, and customization options. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Standard Machines | Basic profile production | $250,000–$400,000 |

| Advanced Machines | High-speed and multi-profile output | $400,000–$600,000 |

| Customizable Machines | Including punching, IoT, and automation | $600,000–$900,000 |

For detailed pricing and financing options, contact Wuxi Sunway Machinery.

Market Trends for Highway Guardrail Roll Forming Machines in 2025

The demand for Highway Guardrail Roll Forming Machines is growing rapidly, driven by global infrastructure development and increasing road safety awareness. Key trends include:

1. Expanding Road Networks

- The Trend: Governments and private sectors are investing in new highways and road expansions.

- Impact on Machines:

- Increased demand for high-volume guardrail production.

- Machines must deliver consistent quality at high speeds.

2. Focus on Sustainable Materials

- The Push: Manufacturers are exploring eco-friendly materials for guardrails, such as recyclable steel.

- How Machines Help:

- Support processing of sustainable materials.

- Align with green infrastructure initiatives.

3. Rising Safety Standards

- The Opportunity: Stricter safety regulations are driving demand for guardrails that meet international standards.

- Why It Matters:

- Machines must ensure compliance with certifications like AASHTO and EN 1317.

- Supports manufacturers in entering global markets.

4. Adoption of Smart Manufacturing

- The Shift: IoT and AI are transforming guardrail manufacturing into a data-driven process.

- Impact on Machines:

- Real-time monitoring enhances production efficiency.

- Predictive maintenance minimizes downtime.

FAQs About Highway Guardrail Roll Forming Machines

| Question | Answer |

|---|---|

| Can one machine produce multiple profiles? | Yes, Wuxi Sunway machines can produce W-beam, thrie-beam, and custom profiles. |

| What is the average production speed? | Machines can produce up to 30–50 meters per minute, depending on the profile complexity. |

| Do these machines support custom designs? | Absolutely! Customizable tooling allows for tailored guardrail profiles to meet project needs. |

| How is material waste minimized? | Precision rollers and cutting systems optimize material usage, reducing scrap. |

| What materials can the machine handle? | Machines are compatible with galvanized steel, stainless steel, and high-strength alloys. |

| Does Wuxi Sunway provide training? | Yes, comprehensive training and after-sales support are included with every machine purchase. |

Technological Advancements in Highway Guardrail Roll Forming Machines

The evolution of Highway Guardrail Roll Forming Machines is driven by the need for efficiency, precision, and sustainability. Here are some of the latest innovations transforming the industry:

1. AI-Assisted Quality Control

- How It Works: Artificial intelligence algorithms monitor the production process in real time, identifying defects or deviations from specifications.

- Why It’s Revolutionary:

- Ensures every guardrail meets exacting safety standards.

- Reduces waste by detecting flaws early in the production cycle.

- Enhances overall product consistency and reliability.

2. Automated Profile Switching

- What It Does: Enables seamless transitions between different guardrail profiles, such as W-beam, thrie-beam, and custom designs.

- Why It’s Beneficial:

- Eliminates manual reconfigurations, saving time and labor.

- Increases production flexibility for manufacturers handling diverse orders.

- Supports just-in-time manufacturing for infrastructure projects.

3. Advanced Cutting Systems

- What It Adds: High-precision hydraulic or laser cutting systems ensure smooth edges and exact lengths.

- Why It’s Critical:

- Produces burr-free cuts, reducing the need for secondary finishing.

- Supports customizations, such as varying lengths or special end designs.

4. IoT Integration

- What It Provides: Internet of Things (IoT) sensors collect and transmit data on machine performance, energy consumption, and material usage.

- Why It’s Important:

- Enables predictive maintenance, minimizing unplanned downtime.

- Optimizes production by identifying inefficiencies or bottlenecks.

- Facilitates remote monitoring for manufacturers managing multiple facilities.

5. Energy-Efficient Motors

- The Innovation: Machines are equipped with energy-saving motors and optimized power systems.

- Why It’s Significant:

- Reduces electricity consumption, lowering operational costs.

- Aligns with sustainability initiatives in manufacturing.

6. Enhanced Punching Capabilities

- What It Offers: Integrated punching systems are capable of creating holes, slots, and notches with high precision.

- Why It’s Practical:

- Facilitates easy installation of guardrails onto posts.

- Supports custom punch patterns for unique project requirements.

Real-World Examples: Highway Guardrail Roll Forming Machines in Action

The versatility and efficiency of Highway Guardrail Roll Forming Machines enable manufacturers to meet the safety demands of infrastructure projects worldwide. Here are some real-world scenarios where these machines make an impact:

1. National Highway Expansion Projects

- Scenario: A government invests in a nationwide highway expansion program to improve connectivity and reduce travel times.

- Machine Contribution:

- Produces W-beam guardrails for long stretches of highway.

- Ensures high-speed production to meet strict deadlines.

- Delivers profiles that comply with local and international safety standards.

2. Bridge Renovation Projects

- Scenario: An engineering firm upgrades the safety features of an aging bridge to handle increased traffic.

- Machine Contribution:

- Crafts thrie-beam guardrails for enhanced impact resistance.

- Supports custom dimensions to fit the bridge’s unique design.

- Produces corrosion-resistant profiles suitable for outdoor exposure.

3. Urban Road Safety Enhancements

- Scenario: A city implements a road safety initiative to reduce accidents at dangerous intersections and curves.

- Machine Contribution:

- Produces guardrails with specific lengths and angles for urban roadways.

- Supports small-batch production for localized safety improvements.

- Ensures precision and uniformity across all components.

4. Coastal Highway Development

- Scenario: A coastal highway is constructed to connect remote towns and boost tourism.

- Machine Contribution:

- Produces guardrails with special coatings to resist saltwater corrosion.

- Crafts custom designs that blend functionality with scenic aesthetics.

- Delivers durable profiles capable of withstanding harsh weather conditions.

5. Industrial Safety Zones

- Scenario: A manufacturing facility installs guardrails to protect workers and vehicles in high-risk areas.

- Machine Contribution:

- Crafts HAT-shaped guardrails for enhanced impact absorption.

- Supports custom installations tailored to the facility’s layout.

- Ensures compliance with workplace safety regulations.

Global Standards Compliance for Highway Guardrails

Highway guardrails must adhere to strict international standards to ensure their effectiveness in protecting lives. Wuxi Sunway Highway Guardrail Roll Forming Machines are designed to produce profiles that meet these requirements:

| Standard | Region | Requirement |

|---|---|---|

| AASHTO M180 | North America | Governs the materials and dimensions for guardrails. |

| EN 1317 | Europe | Specifies performance classes for road restraint systems. |

| ISO 9001 | Global | Ensures consistent quality management across manufacturing processes. |

| AS/NZS 3845 | Australia/New Zealand | Covers road safety barrier systems in compliance with local regulations. |

| GB/T 31439.1 | China | Governs the technical requirements for highway safety barriers. |

By using Wuxi Sunway Roll Forming Machines, manufacturers can confidently produce guardrails that meet these global standards, opening doors to international markets.

Environmental Impact of Guardrail Production

Sustainability is a growing focus in infrastructure development. Here’s how Highway Guardrail Roll Forming Machines contribute to eco-friendly manufacturing:

1. Use of Recyclable Materials

- What It Means: Guardrails are typically made from steel or aluminum, which are recyclable materials.

- Environmental Benefit:

- Promotes a circular economy by enabling material reuse.

- Reduces reliance on virgin raw materials.

2. Energy-Efficient Production

- The Feature: Advanced motors and optimized workflows minimize energy usage.

- Why It Matters:

- Lowers the carbon footprint of manufacturing processes.

- Reduces operational costs for manufacturers.

3. Precision Engineering

- What It Achieves: High-precision rollers and cutting systems minimize scrap generation.

- Environmental Impact:

- Conserves raw materials.

- Reduces waste disposal requirements.

4. Long-Lasting Components

- The Advantage: Roll-formed guardrails are engineered for durability, resisting corrosion and wear.

- Why It’s Sustainable:

- Extends the lifecycle of guardrails, reducing the need for frequent replacements.

- Supports infrastructure longevity with minimal environmental impact.

Expanded FAQ Section for Highway Guardrail Roll Forming Machines

| Question | Answer |

|---|---|

| Can these machines handle custom profiles? | Yes, Wuxi Sunway machines support fully customizable tooling for unique guardrail designs. |

| How long does installation take? | Installation typically takes 4–6 weeks, depending on the machine’s complexity and site readiness. |

| What maintenance is required? | Regular maintenance includes lubrication, roller inspection, and software updates, ensuring optimal performance. |

| Are these machines suitable for global exports? | Absolutely! Wuxi Sunway machines are designed to meet international standards like AASHTO and EN 1317. |

| Can machines integrate with existing systems? | Yes, IoT and modular designs enable seamless integration with existing production lines. |

| What is the lifespan of these machines? | With proper maintenance, Wuxi Sunway machines can last 15–25 years or more. |

Why Wuxi Sunway Machinery is the Go-To Solution

Wuxi Sunway Machinery is a global leader in roll-forming technology, offering unmatched expertise, innovation, and customer support. Here’s why manufacturers choose Wuxi Sunway:

- Unrivaled Expertise: Decades of experience in roll-forming solutions for critical infrastructure.

- Global Presence: Trusted by clients across Asia, Europe, the Americas, and beyond.

- Advanced Technology: Industry-leading features like IoT integration, AI quality control, and modular tooling.

- Sustainability Focus: Machines designed to support eco-friendly manufacturing practices.

- Reliable Support: Comprehensive training, installation, and after-sales service ensure seamless operations.

Conclusion: Safer Roads Start with Precision Engineering

The Highway Guardrail Roll Forming Machine is more than a manufacturing tool—it’s a vital contributor to global road safety. By producing high-quality guardrails that meet international standards, these machines empower infrastructure projects to protect lives and build a safer future.

Ready to upgrade your guardrail production capabilities? Contact Wuxi Sunway Machinery today to explore their cutting-edge roll-forming solutions. Together, let’s ensure safer roads—one guardrail at a time!