The construction industry has always been a cornerstone of global development, and as we move into 2025, the demand for quicker, more efficient, and cost-effective building solutions is higher than ever. At the forefront of meeting this demand are Floor Slab Roll Forming Machines, which are transforming the way steel floor slabs are manufactured for use in residential, commercial, and industrial construction.

These machines are designed to produce high-quality, durable, and precision-engineered floor slabs that serve as the foundation for modern multi-story buildings. Whether it’s for skyscrapers, parking garages, or prefabricated structures, Floor Slab Roll Forming Machines offer a faster, more reliable, and eco-friendly way to meet the increasing need for strong, lightweight, and customizable floor systems.

In this guide, we’ll explore the applications, features, pricing, and benefits of floor slab roll forming machines. We’ll also analyze market trends, technological advancements, and the environmental benefits of these machines. Finally, we’ll highlight why Wuxi Sunway Machinery is a trusted name in this space.

What is a Floor Slab Roll Forming Machine?

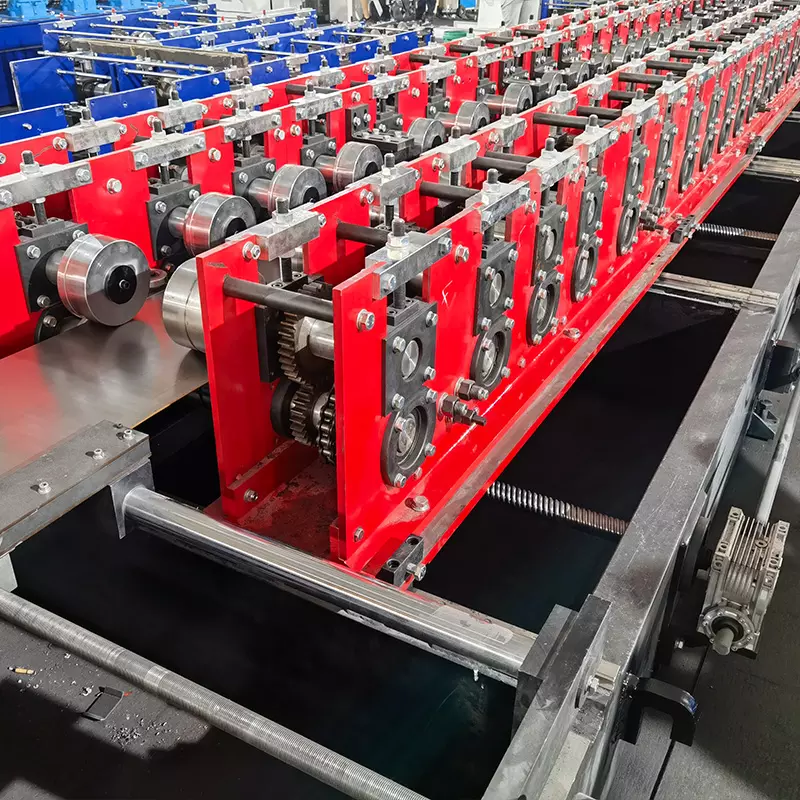

A Floor Slab Roll Forming Machine is a specialized industrial machine designed to produce metal floor decking or slabs used in construction projects. These slabs often serve as structural components in reinforced concrete floor systems, providing a base for concrete pouring while reinforcing the overall structure.

The machine works by taking raw steel coils, passing them through a series of rollers, and shaping them into precise slab profiles. These profiles often have corrugated or ribbed surfaces, which increase the slab’s strength and ensure better bonding with concrete. The result? A sturdy, lightweight, and cost-effective flooring solution that meets modern construction standards.

Applications of Floor Slab Roll Forming Machines

Floor slabs manufactured by roll-forming machines are widely used in various construction projects. Below are the primary applications:

1. Multi-Story Residential Buildings

- Use Case: Steel floor slabs for apartments, condominiums, and housing complexes.

- Why It Matters: Lightweight slabs reduce the overall structural load, making them ideal for high-rise buildings.

2. Commercial Buildings

- Use Case: Decking systems for office complexes, shopping malls, and hotels.

- Why It’s Crucial: Roll-formed slabs provide excellent load-bearing capabilities for expansive commercial floors.

3. Industrial Facilities

- Use Case: Floor slabs for warehouses, factories, and workshops.

- Why It’s Important: Durable and robust slabs can withstand heavy machinery and equipment loads.

4. Parking Garages

- Use Case: Multi-level parking structures requiring strong, lightweight floors.

- Why It’s Relevant: Corrugated steel slabs are highly durable and resistant to wear and tear.

5. Prefabricated and Modular Construction

- Use Case: Floor decking systems for prefabricated homes and modular buildings.

- Why It’s Exciting: Roll-forming machines enable mass production of slabs, speeding up construction timelines.

6. Bridges and Overpasses

- Use Case: Steel decking for bridge floors and overpass structures.

- Why It Matters: Roll-formed slabs provide the necessary strength and flexibility for infrastructure projects.

Key Features of Wuxi Sunway Floor Slab Roll Forming Machines

Wuxi Sunway Machinery specializes in designing and manufacturing roll-forming machines tailored to the needs of the construction industry. Here are the standout features of their Floor Slab Roll Forming Machines:

1. High-Precision Rollers

- What It Ensures: Rollers designed for precision shaping of slab profiles with tight tolerances.

- Why It’s Crucial: Guarantees uniformity and accuracy in every slab, reducing installation errors.

2. Multi-Profile Compatibility

- What It Supports: Machines can produce various slab profiles, including trapezoidal, corrugated, and custom designs.

- Why It Matters: Enhances flexibility for manufacturers catering to diverse construction needs.

3. High-Speed Production

- Performance: Capable of producing up to 30 meters of slab profiles per minute, depending on the design.

- Why It’s Relevant: Meets the high-volume demands of large-scale construction projects.

4. Material Versatility

- Supported Materials:

- Galvanized steel

- Stainless steel

- Pre-coated metals

- Aluminum alloys

- Why It’s Important: Enables manufacturers to produce slabs suitable for different environments and structural requirements.

5. Automated Punching Systems

- What It Includes: Integrated punching systems for creating holes and slots for fasteners or conduits.

- Why It’s Revolutionary: Reduces post-production processing and speeds up installation.

6. PLC-Controlled Operations

- What It Offers: Fully automated operations controlled by a programmable logic controller (PLC) with a user-friendly interface.

- Why It’s Essential: Simplifies operation, reduces labor requirements, and ensures consistent quality.

7. Energy-Efficient Design

- What It Provides: Energy-saving motors and optimized power consumption systems.

- Why It Matters: Reduces operational costs and supports green manufacturing initiatives.

8. Durable Construction

- What It Guarantees: High-grade components designed for long-term reliability.

- Why It’s Important: Reduces maintenance costs and ensures uninterrupted production.

Production Workflow of a Floor Slab Roll Forming Machine

The production process for floor slabs is designed to be efficient and precise. Here’s an overview of the workflow:

1. Material Feeding

- Steel coils are loaded onto the machine’s decoiler, which feeds the material into the rollers.

2. Leveling

- A leveling system ensures the material is flat and free from defects before entering the roll-forming section.

3. Roll Forming

- The material passes through a series of rollers that gradually shape it into the desired slab profile.

4. Punching and Cutting

- Integrated systems create holes, slots, or custom edges, and cut the slabs to the required lengths.

5. Quality Inspection

- Each slab is inspected for dimensional accuracy and surface finish to ensure compliance with design specifications.

6. Stacking and Packaging

- Finished slabs are automatically stacked and packaged for easy transportation and installation.

Pricing of Floor Slab Roll Forming Machines

The cost of a Floor Slab Roll Forming Machine depends on its features, production capacity, and level of automation. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Standard Machines | Basic slab production | $150,000–$300,000 |

| Advanced Machines | High-speed and multi-profile output | $300,000–$500,000 |

| Fully Customizable Machines | Including punching and IoT-enabled systems | $500,000–$750,000 |

For detailed pricing and financing options, contact Wuxi Sunway Machinery.

Environmental Benefits of Floor Slab Roll Forming Machines

Sustainability is a growing priority in the construction industry, and Floor Slab Roll Forming Machines contribute to eco-friendly practices in several ways:

1. Material Efficiency

- How It Works: The roll-forming process shapes metal with high precision, minimizing scrap and offcuts.

- Impact:

- Conserves valuable raw materials.

- Reduces waste sent to landfills.

- Lowers production costs for manufacturers.

2. Use of Recyclable Materials

- What It Supports: Machines process recyclable materials like galvanized steel and aluminum.

- Why It Matters:

- Promotes a circular economy by enabling material reuse.

- Reduces environmental impact at the end-of-life stage for slabs.

- Aligns with green building certifications.

3. Energy-Efficient Operation

- The Innovation: Modern machines consume less energy while maintaining high production speeds.

- Why It’s Crucial:

- Helps manufacturers reduce their carbon footprint.

- Supports sustainable construction initiatives.

- Improves overall operational efficiency.

4. Localization of Production

- What It Enables: Manufacturers can produce slabs locally, reducing the need for long-distance transportation.

- Outcome:

- Cuts down on emissions associated with shipping.

- Enhances supply chain reliability and regional sustainability.

FAQs About Floor Slab Roll Forming Machines

| Question | Answer |

|---|---|

| Can the machine produce custom slab designs? | Yes, modular tooling systems allow for the production of custom profiles. |

| What is the machine’s production speed? | Machines can produce up to 30 meters of slab profiles per minute, depending on the design. |

| Does Wuxi Sunway provide after-sales support? | Yes, comprehensive support, including training and troubleshooting, is offered. |

| What is the expected lifespan of the machine? | With proper maintenance, these machines can last 10–15 years or more. |

| Are financing options available? | Yes, flexible financing options are offered to qualified buyers. |

| What industries use this machine? | Industries include residential, commercial, industrial, and prefabricated construction sectors. |

Technological Advancements in Floor Slab Roll Forming Machines

The capabilities of Floor Slab Roll Forming Machines have expanded significantly over the years, fueled by innovations in automation, digitalization, and material science. Here’s a closer look at the cutting-edge technologies shaping the future of these machines:

1. Smart Automated Systems

- What It Does: Fully automated machines equipped with real-time sensors and programmable logic controllers (PLCs).

- Benefits:

- Reduces manual intervention, ensuring consistent output quality.

- Enables operators to manage multiple machines simultaneously.

- Improves production speed and accuracy.

2. IoT-Enabled Connectivity

- How It Works: Internet of Things (IoT) integration allows machines to communicate with factory systems, collect data, and provide actionable insights.

- Advantages:

- Predictive maintenance reduces downtime and extends machinery lifespan.

- Real-time monitoring ensures efficient energy usage and process optimization.

- Remote accessibility for diagnostics and troubleshooting.

3. AI-Driven Quality Control

- The Feature: Artificial intelligence algorithms monitor every stage of slab production to detect defects and inconsistencies.

- Why It’s Revolutionary:

- Reduces waste by identifying flaws early in the process.

- Ensures that every slab meets stringent quality standards.

- Enhances customer satisfaction by delivering defect-free products.

4. Multi-Profile Forming Capability

- What It Enables: Machines can produce multiple slab profiles, including trapezoidal, ribbed, and custom designs, without requiring extensive retooling.

- Why It’s Important:

- Provides flexibility to cater to diverse customer needs.

- Reduces time and cost associated with tooling changes.

- Supports manufacturers looking to expand their product offerings.

5. High-Speed Production with Precision

- The Innovation: Advanced roller systems and optimized drive mechanisms enable machines to operate at speeds of up to 30 meters per minute.

- Why It’s Crucial:

- Meets the high demand for floor slabs in large construction projects.

- Maintains precision and consistency even at high speeds.

- Reduces lead times, enabling manufacturers to meet tight project deadlines.

6. Energy-Efficient Motors

- What It Includes: Machines are equipped with energy-efficient motors that reduce power consumption without compromising performance.

- Why It Matters:

- Aligns with global sustainability goals.

- Lowers operational costs, improving profitability.

- Supports green manufacturing certifications.

7. Modular Machine Design

- What It Offers: Machines can be configured with additional modules, such as punching systems, embossing units, or edge trimming tools.

- Why It’s Beneficial:

- Enables manufacturers to customize machines to their specific needs.

- Reduces the need for separate processing steps.

- Scales production capabilities as business grows.

Market Adoption Trends in 2025

The adoption of Floor Slab Roll Forming Machines is accelerating globally, driven by key trends in the construction and infrastructure sectors. Let’s explore what’s fueling this growth:

1. Rise of Modular Construction

- The Trend: Modular construction, where buildings are assembled from prefabricated components, is gaining popularity due to its speed and cost efficiency.

- Impact on Roll Forming Machines:

- High demand for pre-engineered floor slabs that can be quickly installed on-site.

- Roll-forming technology supports mass production of modular components, reducing construction timelines.

2. Urbanization and Infrastructure Development

- The Numbers: By 2050, it is estimated that 68% of the global population will live in urban areas, driving the need for housing and infrastructure.

- Why It Matters:

- Floor slab roll forming machines enable the rapid production of flooring systems for multi-story buildings, bridges, and public spaces.

- Advanced machines can meet the demands of large-scale urban development projects.

3. Push for Sustainability

- The Goal: Governments and construction companies are prioritizing eco-friendly practices to reduce the environmental impact of building projects.

- How Roll Forming Machines Help:

- Machines use recyclable materials like galvanized steel, promoting a circular economy.

- Energy-efficient designs reduce the carbon footprint of manufacturing processes.

4. Demand for Lightweight Materials

- The Trend: Lightweight construction materials are becoming more popular for their ease of transportation and installation, especially in high-rise buildings.

- Why It’s Relevant:

- Roll-formed slabs are lightweight yet structurally robust, making them ideal for modern construction.

- Machines can produce slabs that reduce overall building weight without compromising strength.

5. Expansion of Prefabrication Facilities

- The Shift: Prefabrication plants are being set up closer to construction sites to reduce transportation costs and emissions.

- Impact on Roll Forming Machines:

- Manufacturers are investing in localized production capabilities using roll-forming machines.

- Machines with modular designs are ideal for setting up efficient, scalable production lines in prefabrication facilities.

Business Benefits of Using Floor Slab Roll Forming Machines

Investing in a high-quality Floor Slab Roll Forming Machine offers a range of advantages for manufacturers and construction companies:

1. Enhanced Productivity

- How It Helps:

- High-speed production reduces manufacturing timelines.

- Automation minimizes errors and labor requirements.

- Modular systems allow for the seamless addition of new features.

2. Cost Efficiency

- What It Saves:

- Reduces material waste through precision shaping.

- Lowers energy costs with efficient motors and systems.

- Decreases reliance on manual labor, cutting workforce expenses.

3. Scalability

- Why It’s Important:

- Machines can handle small-scale projects as well as large-scale production demands.

- Modular designs allow for upgrades to meet future business needs.

- Customizable profiles cater to a broader range of applications.

4. Competitive Advantage

- What It Provides:

- High-quality slabs enhance the reputation of manufacturers.

- Faster production times help secure contracts for time-sensitive projects.

- Advanced features like IoT integration and AI-driven quality control set companies apart from competitors.

5. Sustainability Alignment

- The Impact:

- Eco-friendly production processes attract clients looking for green construction solutions.

- Machines support compliance with green building certifications like LEED.

- Reduced carbon footprint enhances brand reputation in the market.

Additional FAQs About Floor Slab Roll Forming Machines

| Question | Answer |

|---|---|

| What types of profiles can the machine produce? | Machines can produce trapezoidal, ribbed, corrugated, and custom slab profiles. |

| Can the machine handle galvanized materials? | Yes, machines are designed to process galvanized steel, aluminum alloys, and other materials. |

| Does Wuxi Sunway offer installation services? | Absolutely! Installation and training services are provided to ensure seamless operations. |

| What is the typical lead time for delivery? | Delivery times range from 3 to 6 months, depending on customization and order volume. |

| Are warranty options available? | Yes, Wuxi Sunway offers warranties and comprehensive support packages. |

| What industries use this machine? | Industries include residential construction, commercial buildings, prefabrication, and infrastructure. |

Why Wuxi Sunway Machinery is the Leader in Roll Forming Solutions

When it comes to Floor Slab Roll Forming Machines, Wuxi Sunway Machinery stands out as a global leader. Here’s why:

- Industry Expertise: Decades of experience in delivering innovative roll-forming solutions tailored to the construction industry.

- Customization Excellence: Machines are designed to meet specific customer requirements, ensuring maximum utility and efficiency.

- Global Presence: Trusted by manufacturers across Asia, Europe, the Americas, and beyond.

- Sustainability Commitment: Eco-friendly designs that promote material efficiency and energy savings.

- Cutting-Edge Technology: Incorporates IoT, AI, and modular systems for advanced performance and reliability.

- End-to-End Support: Comprehensive services, including installation, training, maintenance, and troubleshooting.

Conclusion: Building the Future with Precision and Efficiency

The Floor Slab Roll Forming Machine is a cornerstone of modern construction, offering unparalleled efficiency, versatility, and sustainability. Whether you’re building residential high-rises, industrial facilities, or prefabricated structures, these machines provide the precision and scalability required to succeed in today’s competitive market.

Ready to elevate your production capabilities? Partner with Wuxi Sunway Machinery today to explore their world-class roll-forming solutions. Together, let’s construct the future—one slab at a time!