When it comes to modern steel construction, C and Z purlins are the backbone of structural integrity. These lightweight yet incredibly strong components are widely used to support roofs, walls, and flooring systems in a variety of buildings. But what makes the manufacturing of purlins even more efficient and versatile? The answer lies in the CZ Purlin Interchangeable Roll Forming Machine—a cutting-edge solution that enables manufacturers to rapidly switch between C and Z profiles, saving time, reducing costs, and boosting productivity.

In this comprehensive guide, we’ll explore everything about CZ Purlin Interchangeable Roll Forming Machines, from their features and applications to pricing and advantages. We’ll also highlight how Wuxi Sunway Machinery, a globally renowned leader in roll-forming technology, is setting the gold standard with its innovative and high-performance machines.

What is a CZ Purlin Interchangeable Roll Forming Machine?

A CZ Purlin Interchangeable Roll Forming Machine is advanced equipment designed to produce C and Z-shaped steel purlins, two of the most commonly used structural components in steel construction. What sets this machine apart from traditional roll-forming machines is its interchangeable design, allowing seamless switching between C and Z profiles without significant downtime.

This versatility eliminates the need for separate machines or lengthy retooling processes, making it an ideal choice for manufacturers catering to diverse customer demands. With advanced automation, precision forming, and customizable settings, the CZ Purlin Interchangeable Roll Forming Machine is a game-changer for the steel construction industry.

Applications of C and Z Purlins in Construction

C and Z purlins are indispensable for various construction projects due to their strength, durability, and lightweight properties. Let’s explore their key applications:

1. Roofing Systems

- Use Case: Purlins act as horizontal supports to hold up metal roofing sheets, ensuring stability and load distribution.

2. Wall Framing

- Use Case: These components are used as girts to support wall cladding, providing a firm and aligned framework.

3. Industrial Sheds and Warehouses

- Use Case: C and Z purlins are ideal for large-span structures like warehouses and factories due to their high load-bearing capacity.

4. Commercial Buildings

- Use Case: From shopping malls to office complexes, purlins are essential for creating strong yet lightweight framing systems.

5. Agricultural Structures

- Use Case: Barns, greenhouses, and silos rely on purlins for roofing and wall support, ensuring durability against harsh weather.

6. Solar Mounting Systems

- Use Case: Z purlins, in particular, are widely used for mounting solar panels due to their flexibility and ease of installation.

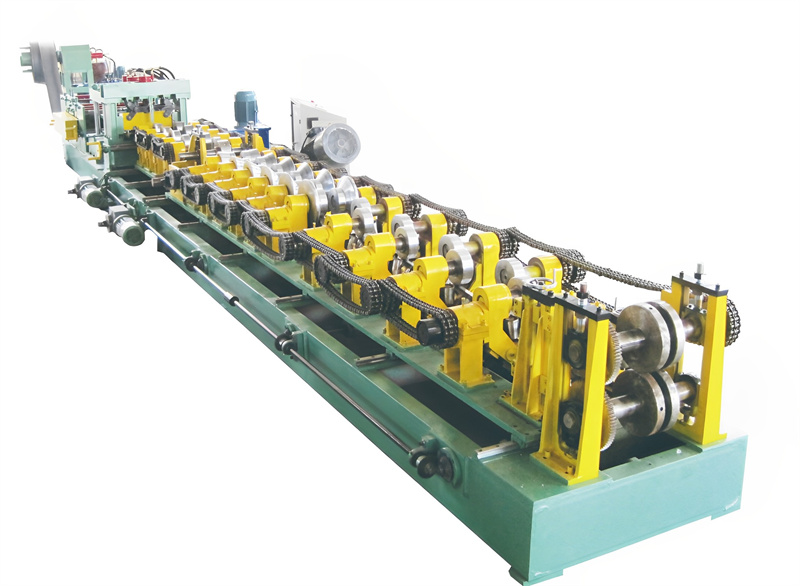

Key Features of Wuxi Sunway CZ Purlin Interchangeable Roll Forming Machines

When it comes to state-of-the-art roll-forming technology, Wuxi Sunway Machinery leads the pack. Their CZ Purlin Interchangeable Roll Forming Machines are packed with advanced features designed to maximize efficiency, versatility, and precision. Here’s what sets them apart:

1. Seamless Profile Switching

- What It Does: Allows for quick and automatic switching between C and Z profiles without manual retooling.

- Why It’s Important: Saves time and boosts productivity, especially for manufacturers handling diverse orders.

2. Adjustable Sizes

- Capabilities: Produces purlins in various sizes, with adjustable widths, heights, and flange angles.

- Why It Matters: Offers flexibility to meet different project requirements and customer specifications.

3. High-Speed Production

- Performance: Capable of producing up to 20 meters of purlins per minute, depending on material and design.

- Why It Matters: Increases production efficiency to meet tight deadlines for large-scale projects.

4. Precision Punching

- What It Does: Integrates hydraulic or servo-driven punching systems to create pre-punched holes for bolts and screws.

- Why It’s Useful: Streamlines installation and eliminates the need for secondary operations.

5. Advanced Cutting Technology

- How It Works: Servo-controlled cutting ensures clean, burr-free cuts to the required lengths.

- Why It Matters: Enhances product quality and reduces material waste.

6. Material Compatibility

- Supported Materials:

- Galvanized steel

- Mild steel

- High-tensile steel

- Thickness Range: 1.5mm–3.0mm

- Why It’s Important: Ensures versatility for various applications, from lightweight to heavy-duty projects.

7. PLC-Controlled Automation

- Features:

- Fully programmable logic controllers (PLC) with an intuitive touchscreen interface.

- Stores multiple purlin profiles and production parameters.

- Real-time performance monitoring and error detection.

- Why It Matters: Simplifies operation and ensures consistent quality, even across large production runs.

8. Compact and Modular Design

- What It Offers: Space-saving design that integrates easily into existing production lines.

- Why It Matters: Optimizes factory floor space and allows for future upgrades.

9. Safety Features

- Highlights:

- Emergency stop buttons for immediate shutdown.

- Overload protection to prevent damage during operation.

- Protective covers for moving parts.

- Why It’s Important: Ensures operator safety and prolongs machine lifespan.

Production Workflow of a CZ Purlin Interchangeable Roll Forming Machine

Here’s how the machine efficiently transforms raw steel coils into high-quality C and Z purlins:

1. Decoiling

- Steel coils are loaded into the decoiler, which feeds the material into the machine.

2. Leveling

- A leveling system ensures the material is flat and free from warping before entering the roll-forming section.

3. Punching

- Hydraulic or servo-driven punching units create slots, holes, or embossments as required by the design.

4. Roll Forming

- The material passes through a series of precision-engineered rollers, gradually shaping it into the desired C or Z profile.

5. Cutting

- A servo-driven cutting system trims the purlins to the specified lengths with clean, burr-free edges.

6. Stacking

- Finished purlins are automatically stacked for easy packaging and transportation.

Pricing of CZ Purlin Interchangeable Roll Forming Machines

The cost of a CZ Purlin Interchangeable Roll Forming Machine depends on its features, production capacity, and level of automation. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Basic Machines | Standard C and Z purlin production | $80,000–$100,000 |

| High-Speed Machines | Enhanced speed and punching precision | $100,000–$150,000 |

| Fully Customizable Machines | Advanced features and multi-profile capability | $150,000–$200,000 |

For tailored pricing and financing options, contact Wuxi Sunway Machinery.

Advantages of Using a CZ Purlin Interchangeable Roll Forming Machine

Investing in a CZ Purlin Interchangeable Roll Forming Machine offers numerous benefits for manufacturers:

1. Time and Cost Efficiency

- Eliminates the need for separate machines or lengthy retooling, reducing production downtime.

2. Versatility

- Supports a wide range of C and Z purlin sizes and profiles, catering to diverse project requirements.

3. Precision

- Advanced automation ensures consistent quality, minimizing defects and rework.

4. Scalability

- High production capacity allows manufacturers to scale operations as demand grows.

5. Sustainability

- Reduces material waste and energy consumption, aligning with green manufacturing goals.

Troubleshooting Common Issues in CZ Purlin Interchangeable Roll Forming Machines

Even the best machines may encounter occasional issues. Here’s how to address some common problems:

1. Inconsistent Profile Dimensions

- Cause: Misaligned rollers or incorrect settings.

- Solution: Realign the rollers and verify forming parameters in the PLC system.

2. Material Jams

- Cause: Improper feeding or debris in the machine.

- Solution: Clean the rollers and ensure proper material alignment.

3. Cutting Inaccuracies

- Cause: Worn cutting blades or incorrect servo settings.

- Solution: Replace or sharpen the blades and adjust the servo motor parameters.

4. Punching Errors

- Cause: Misaligned punching dies or insufficient hydraulic pressure.

- Solution: Realign the dies and adjust punching parameters in the control system.

For persistent issues, contact the Wuxi Sunway Machinery technical team for expert assistance.

Global Industry Trends Shaping the Demand for CZ Purlin Interchangeable Roll Forming Machines

As the construction and manufacturing industries evolve, several key trends are driving the demand for versatile and efficient roll-forming solutions like the CZ Purlin Interchangeable Roll Forming Machine. Here’s what’s shaping the market in 2025:

1. Increased Adoption of Pre-Engineered Buildings (PEBs)

- The Trend: Pre-engineered buildings (PEBs) are rapidly gaining popularity for industrial, commercial, and agricultural applications due to their cost-effectiveness and faster construction timelines.

- Impact on C and Z Purlins: Purlins are integral to PEBs, forming the framework for roofs and walls.

- Why It Matters: Machines like the CZ Purlin Interchangeable Roll Forming Machine are essential for producing high-quality purlins at scale to meet the growing demand for PEBs.

2. Rising Focus on Lightweight Construction

- What’s Driving It: Lightweight materials are becoming the go-to choice for reducing construction costs and improving structural efficiency.

- Impact on C and Z Purlins: Steel purlins are lightweight yet strong, making them ideal for modern construction projects.

- Machine Relevance: Roll-forming machines capable of producing precise, lightweight purlins are critical to supporting this trend.

3. Push for Customization in Construction

- The Shift: Construction projects increasingly demand customized components to meet specific design and functional requirements.

- Impact on C and Z Purlins: Custom purlin sizes, angles, and hole patterns are becoming common.

- Why It Matters: Advanced machines like those from Wuxi Sunway offer programmable flexibility to cater to diverse customization needs.

4. Expansion of Solar Energy Projects

- The Numbers: The global solar energy market is expected to grow at a compound annual growth rate (CAGR) of over 20% from 2023 to 2030.

- Impact on C and Z Purlins: Solar mounting systems heavily rely on Z-shaped purlins for their structural frameworks.

- Machine Relevance: High-speed, precise roll-forming machines are key to meeting the demand for solar infrastructure components.

5. Technological Advancements in Roll-Forming

- The Evolution: Integration of IoT, PLC systems, and servo-driven mechanisms is revolutionizing the roll-forming industry.

- Impact on CZ Machines: Modern CZ roll-forming machines are smarter, more efficient, and easier to operate.

- Why It’s Exciting: These advancements make machines like the CZ Purlin Interchangeable Roll Forming Machine indispensable for forward-thinking manufacturers.

Technological Advancements in CZ Purlin Interchangeable Roll Forming Machines

Let’s take a closer look at the cutting-edge technologies that are transforming CZ Purlin Interchangeable Roll Forming Machines into powerful, future-ready tools:

1. IoT-Enabled Smart Monitoring

- What It Does: Connects the machine to a cloud-based system for real-time performance tracking and diagnostics.

- Benefits:

- Enables predictive maintenance, reducing unplanned downtime.

- Provides actionable insights for optimizing production efficiency.

- Allows remote monitoring and control via mobile devices or computers.

2. Advanced Servo Motors

- How They Work: Servo motors control the cutting and punching systems with incredible precision and speed.

- Why It Matters:

- Ensures burr-free, accurate cuts and punched holes.

- Reduces material waste, enhancing overall cost efficiency.

3. Intelligent PLC Systems

- Features:

- Fully programmable logic controllers (PLC) with a touchscreen interface.

- Stores multiple purlin profiles and production parameters.

- Provides real-time error detection and troubleshooting guidance.

- Why It’s Revolutionary: Simplifies machine operation, even for operators with limited experience.

4. Automatic Size Adjustment

- What It Does: Automatically adjusts the machine’s rollers and settings to switch between C and Z profiles or change purlin sizes.

- Why It’s Game-Changing: Eliminates the need for manual retooling, saving significant time and labor costs.

5. Integrated Digital Twin Technology

- What It Is: A virtual replica of the machine that simulates production runs for new designs or materials.

- Why It’s Powerful:

- Allows manufacturers to test profiles without wasting materials.

- Speeds up the design and production process for custom components.

6. Enhanced Safety Systems

- Key Features:

- Emergency stop buttons for instant shutdown.

- Overload protection to prevent damage during operation.

- Safety covers for moving parts to protect operators.

- Why It’s Crucial: Ensures a safer working environment while extending the machine’s lifespan.

Environmental Benefits of CZ Purlin Interchangeable Roll Forming Machines

Sustainability is a growing priority for manufacturers, and CZ Purlin Interchangeable Roll Forming Machines align perfectly with this goal. Here’s how they contribute to eco-friendly manufacturing:

1. Reduced Material Waste

- How It Works: Precision forming and cutting systems optimize material usage, minimizing scrap.

- Impact: Lowers production costs and reduces environmental impact.

2. Energy Efficiency

- The Innovation: Machines are equipped with energy-efficient servo motors and hydraulic systems, reducing electricity consumption.

- Why It Matters: Lowers operational costs and carbon emissions, supporting green manufacturing practices.

3. Recyclable Outputs

- The Advantage: Steel purlins produced by these machines are 100% recyclable, aligning with circular economy principles.

- Outcome: Encourages sustainable construction practices and reduces landfill waste.

4. Localized Production

- How It Helps: Roll-forming machines enable localized manufacturing, reducing the need for long-distance transportation.

- Impact: Lowers greenhouse gas emissions associated with logistics.

Comparison: CZ Purlin Interchangeable Roll Forming Machines vs. Traditional Roll-Forming Machines

Let’s examine how CZ Purlin Interchangeable Roll Forming Machines stack up against traditional roll-forming machines:

| Feature | CZ Purlin Interchangeable Roll Forming Machine | Traditional Roll-Forming Machine |

|---|---|---|

| Profile Switching | Fully automated; seamless transition | Manual retooling required; time-consuming |

| Production Speed | High; up to 20 meters per minute | Moderate; slower due to manual adjustments |

| Automation | Advanced PLC, IoT integration | Limited automation |

| Material Waste | Minimal; optimized processes reduce scrap | Higher; less efficient material usage |

| Customization | Easily supports multiple profiles and sizes | Limited to specific profiles |

| Cost Efficiency | Higher initial cost, lower long-term costs | Lower initial cost, higher operational costs |

| Scalability | Ideal for high-volume production | Less suitable for large-scale manufacturing |

Additional FAQs About CZ Purlin Interchangeable Roll Forming Machines

| Question | Answer |

|---|---|

| Can the machine handle high-tensile steel? | Yes, the machine is designed to process high-tensile steel with thicknesses of up to 3.0mm. |

| What is the typical changeover time? | Automatic profile switching takes less than 5 minutes. |

| What is the warranty period? | All Sunway machines come with a 12-month warranty, with extended options available. |

| How long does the installation take? | Installation and commissioning typically take 5–10 days, depending on factory setup. |

| Is operator training included? | Yes, comprehensive training is provided with every machine purchase. |

| Can the machine integrate with other equipment? | Absolutely! Sunway machines are designed for seamless integration into automated production lines. |

Why Choose Wuxi Sunway Machinery for CZ Purlin Interchangeable Roll Forming Machines?

Here’s why Wuxi Sunway Machinery is the trusted partner for roll-forming solutions:

- Proven Expertise: Over two decades of experience in roll-forming technology.

- Global Presence: Trusted by clients across Asia, Europe, Africa, and the Americas.

- Custom Solutions: Machines tailored to meet specific production needs.

- Sustainability: Focused on minimizing waste and energy consumption.

- Innovation: Cutting-edge technology, including IoT and PLC integration.

- Comprehensive Support: From installation to troubleshooting, Sunway provides end-to-end service.

Conclusion: Redefining Steel Construction with Precision and Versatility

The CZ Purlin Interchangeable Roll Forming Machine is more than just a tool—it’s a transformative investment in precision, efficiency, and scalability. With its ability to seamlessly switch between profiles and adapt to diverse project requirements, this machine is a must-have for manufacturers aiming to lead in the competitive steel construction market.

Ready to revolutionize your production process? Contact Wuxi Sunway Machinery today to explore their state-of-the-art roll-forming solutions. Together, let’s shape the future of construction—one purlin at a time!