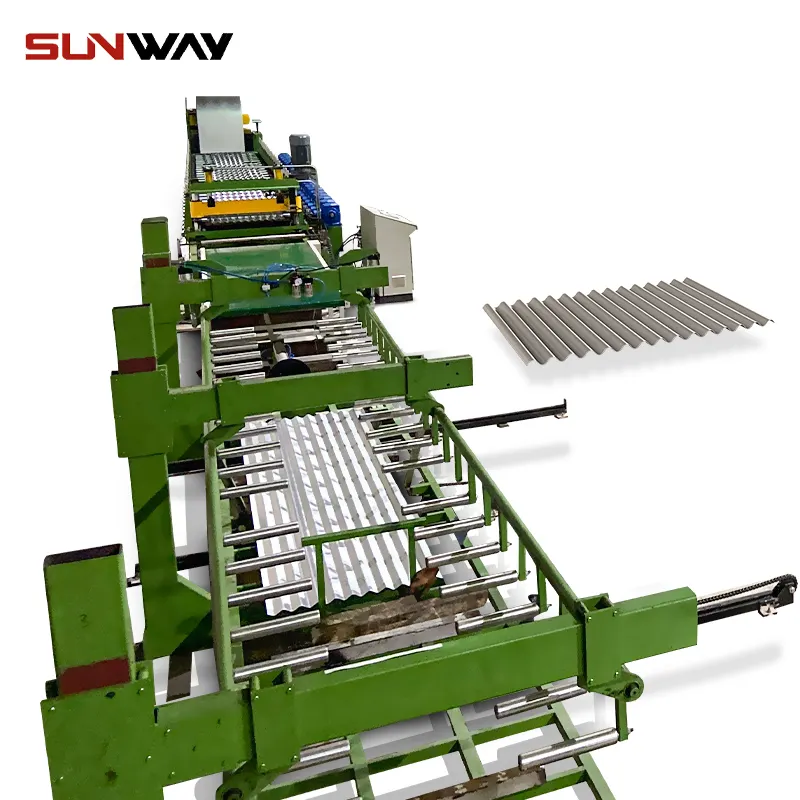

Ag Classic Rib Roof Roll Forming Machine

The ag classic rib roof roll forming machine is an essential equipment for manufacturing ribbed metal roofing panels and decking sheets efficiently. This guide provides a comprehensive overview of ag

The ag classic rib roof roll forming machine is an essential equipment for manufacturing ribbed metal roofing panels and decking sheets efficiently. This guide provides a comprehensive overview of ag

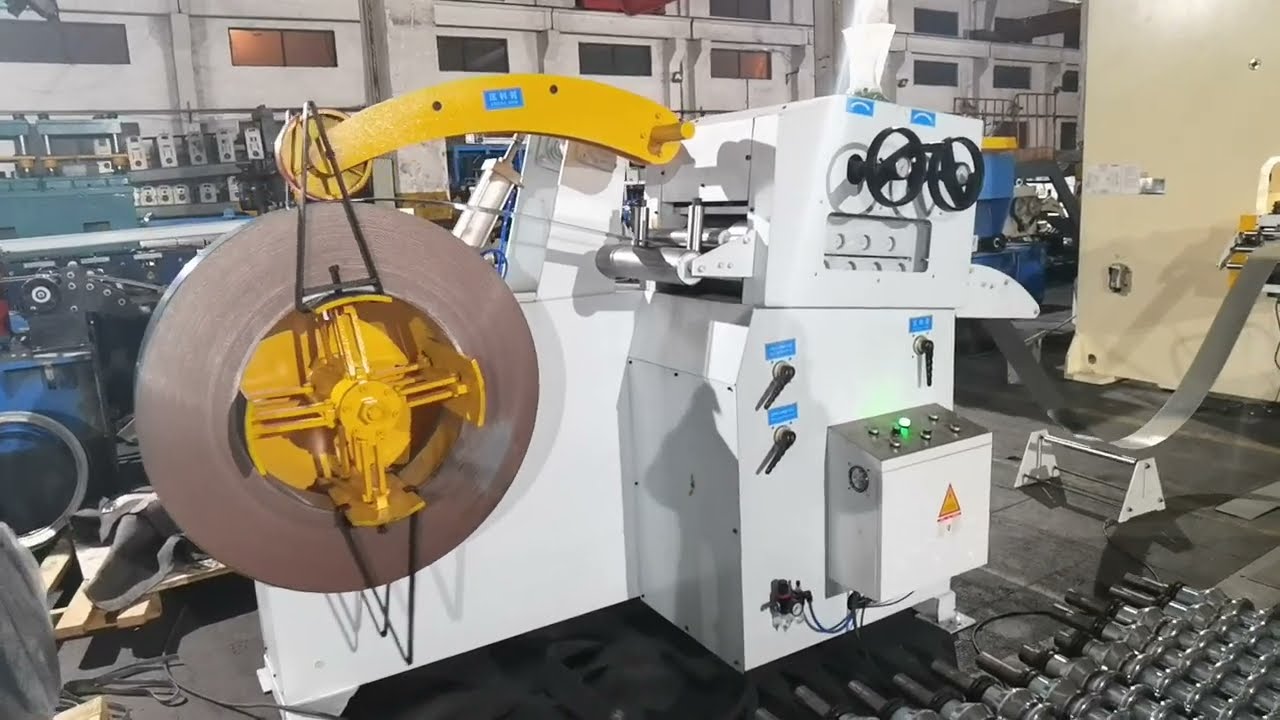

Standing seam roll forming machines are specialized lines designed to continuously form interlocking standing seam metal roof panels from coils of sheet metal. Key features of standing seam roll formers:

Flying-shear roll forming machines utilize a unique cut-to-length system to boost efficiency in roll formed profile production. The flying shear mechanism shears the moving strip just before it enters the

China c/z purlin roll forming machines are widely used for producing cold formed c/z purlins from coil steel. This guide provides a comprehensive overview of c/z purlin roll forming system

C purlin roll forming machines are used to produce C and Z purlins from metal coils. Purlins are structural framing members widely used in metal buildings and roofs. They are

Metal roofing tile roll forming machines are equipment used to produce metal roofing tiles and panels through continuous bending and forming of coil material. These versatile machines allow fast, high-volume

Glazed tile roll forming machines are specialized equipment used to produce glazed ceramic tiles in a continuous automated process. This equipment revolutionized tile manufacturing, enabling mass production of tiles with

Manual roll forming is a metalworking process that uses a series of consecutive stands with contoured rolls to gradually bend metal coil into desired cross-sectional profile shapes. Manual roll forming

Light steel keel roll forming machines are an essential equipment used for manufacturing light steel keels and frames for the construction industry. This guide provides a comprehensive overview of light

Roll forming is a metal working process in which sheet metal is progressively formed into a desired cross-sectional profile through a series of roll stations. Roll formed profiles are used

Roll forming is a metal working process in which sheet metal is gradually bent into a desired cross-sectional profile through a series of roll stations. Stud and track roll forming

Roll forming is a metal forming process used to transform flat sheet metal or coils into customized profiles with complex cross-sections. Roll forming machines are essential equipment for manufacturing precision

Standing seam metal roll forming machines are an essential equipment for manufacturers of metal roofing and siding panels. This comprehensive guide provides an overview of standing seam roll formers, their

Steel gas tube cold roll forming machines are industrial equipment used for bending and forming steel strips into hollow tube sections for gas conduction applications. These machines are highly customizable

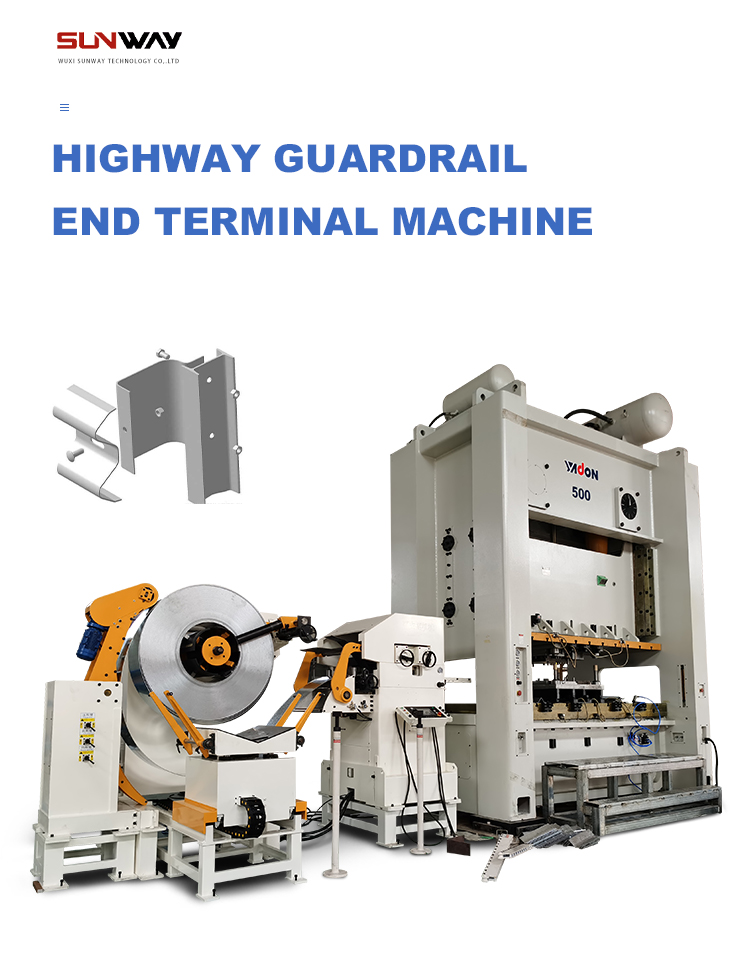

Guardrails are essential safety features installed along roads, highways, bridges, and other infrastructure to prevent vehicles from veering off the edge. Roll forming is a common manufacturing process used to

Introduction Choosing the right roll forming machine is a big decision, but what better way to understand its impact than

Introduction Choosing the right roll forming machine can be challenging—especially with so many options available in the market. Whether you’re

Introduction Automation is revolutionizing the roll forming industry, making production faster, more precise, and less dependent on manual labor. As

Introduction The roll forming industry is undergoing a technological revolution, driven by automation, AI, sustainability, and advanced materials. As we