Imagine a machine that can transform sheets of metal into sleek, weather-resistant panels for your roof. That’s the magic of a Bemo Roof Panel Machine. These marvels of metalworking precision are the backbone of modern standing seam roofing systems, a popular choice for architects, builders, and homeowners alike. But what exactly are Bemo Roof Panel Machines, and how do they work? Buckle up, because we’re diving deep into the world of these fascinating machines!

Function of Bemo Roof Panel Machines

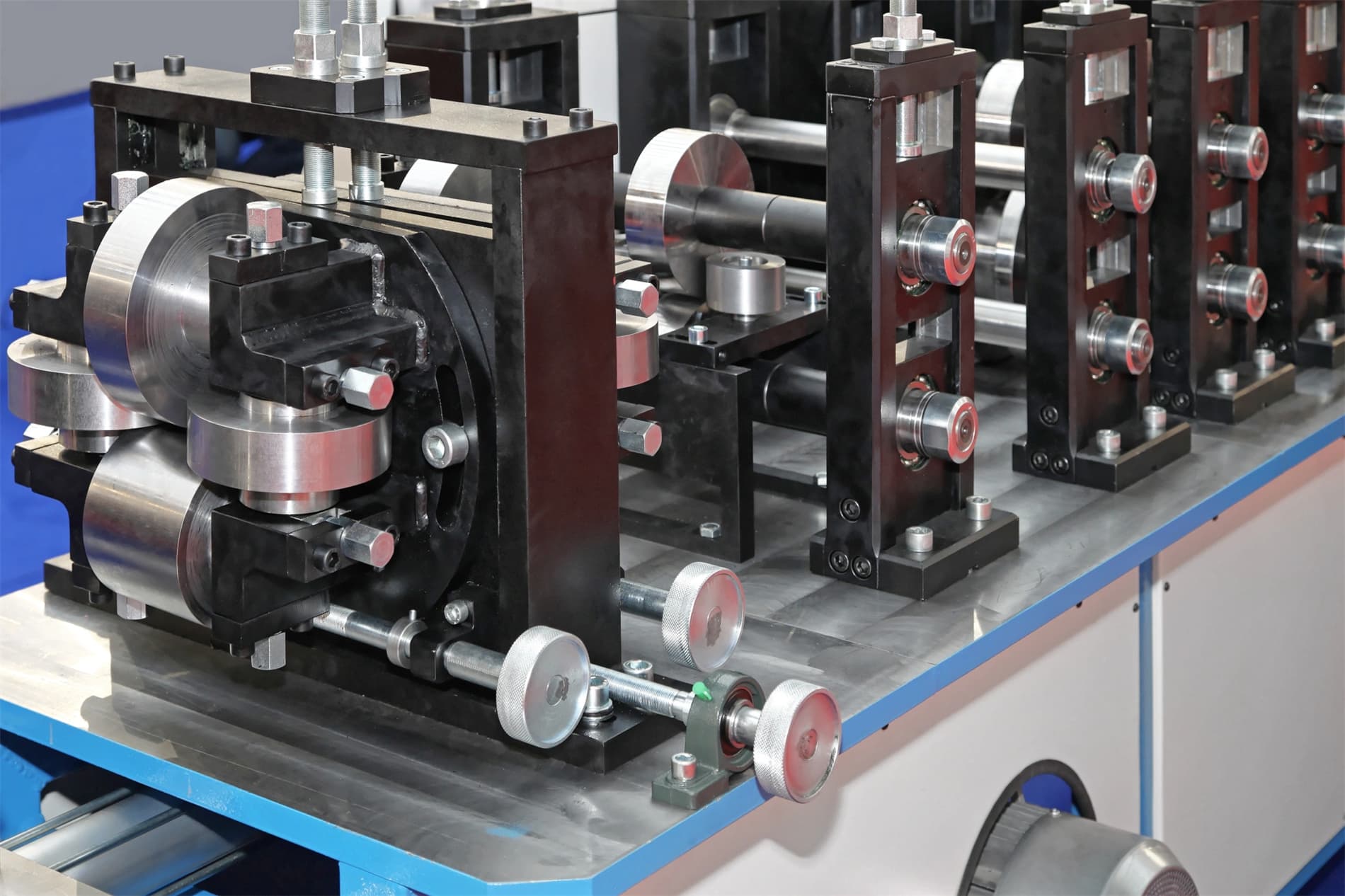

At its core, a Bemo Roof Panel Machine is a roll forming machine specifically designed to create interlocking metal panels for roofing applications. Think of it like a high-tech cookie cutter, but instead of sugary treats, it shapes sheets of metal into precise profiles. Here’s a breakdown of the process:

- Feeding the Machine: Coils of sheet metal, typically aluminum or steel, are fed into the machine.

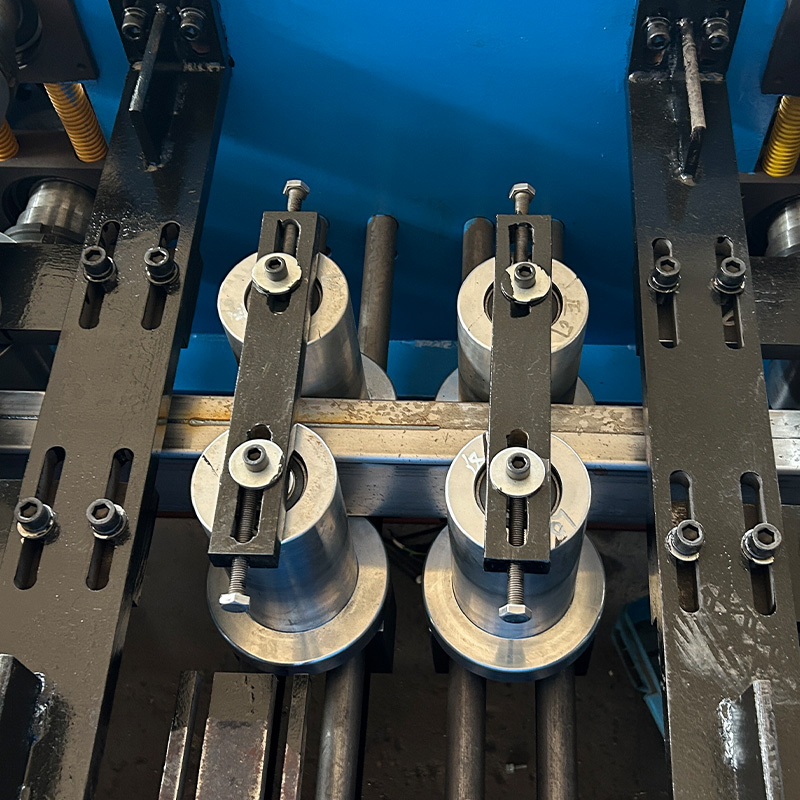

- Roll Forming Magic: The metal sheet is then guided through a series of rollers that progressively bend and shape it into the desired profile. These rollers are engraved with intricate patterns that define the final shape of the panel, including interlocking seams and ribs for added strength.

- Cutting to Length: Once the desired profile is formed, the machine precisely cuts the panel to the specified length.

- Ready for Installation: The finished panels are then stacked and prepared for installation on the roof.

The entire process is automated and remarkably efficient, churning out pre-formed panels at a steady pace. This not only saves time on construction sites but also ensures consistent quality and uniformity in the finished roof.

Benefits of Bemo Roof Panel Machines

Bemo Roof Panel Machines offer several advantages over traditional roofing methods:

- Efficiency: Compared to manually cutting and shaping sheet metal on-site, these machines significantly speed up the roofing installation process.

- Precision: The automated roll forming process guarantees consistent panel profiles, leading to a tighter fit and a more aesthetically pleasing roof.

- Durability: Bemo machines are built to handle various metal gauges, resulting in robust and long-lasting roof panels.

- Versatility: These machines can create a wide range of panel profiles to suit different architectural styles and functional needs.

- Reduced Waste: The precise cutting process minimizes material waste compared to traditional methods.

Types of Bemo Roof Panel Machines

Not all Bemo Roof Panel Machines are created equal. Different models cater to specific needs and offer varying functionalities. Here’s a breakdown of some common types:

- Straight Panel Machines: These machines produce flat panels with interlocking seams on the sides. They are ideal for simple roof designs with straight runs.

- Tapered Panel Machines: These machines create panels that gradually decrease in width along their length. This is particularly useful for conical or curved roof structures.

- High-Capacity Machines: Designed for large-scale projects, these machines boast faster production speeds and can handle wider coils of metal.

- Customizable Machines: Some manufacturers offer machines that can be configured to produce specific panel profiles or accommodate a wider range of metal thicknesses.

Applications of Bemo Roof Panel Machines

Bemo Roof Panel Machines are a popular choice for a variety of roofing applications, including:

- Commercial Buildings: From office complexes to warehouses, Bemo panels offer a durable, weather-resistant, and aesthetically pleasing roofing solution for commercial structures.

- Residential Buildings: Modern homes often utilize standing seam roofs for their clean lines and architectural appeal. Bemo machines make this option more accessible and efficient.

- Industrial Buildings: These machines can produce heavy-duty panels ideal for withstanding harsh weather conditions and industrial environments.

- Curved Roofs: Tapered panel machines are instrumental in creating unique curved roof designs for architectural statements.

Advantages and Considerations

While Bemo Roof Panel Machines offer numerous benefits, there are a few points to consider:

- Initial Investment: The cost of purchasing a Bemo Roof Panel Machine can be significant. However, for professional roofers or companies specializing in standing seam roofs, the return on investment can be substantial due to increased efficiency and productivity.

- Technical Expertise: Operating a Bemo Roof Panel Machine requires a certain level of technical knowledge and training to ensure proper setup, operation, and maintenance.

- Material Compatibility: These machines are typically designed to work with specific types and thicknesses of metal. It’s crucial to choose a machine compatible with the desired roofing material.

Imagine a machine that can transform sheets of metal into sleek, weather-resistant panels for your roof. That’s the magic of a Bemo Roof Panel Machine. These marvels of metalworking precision are the backbone of modern standing seam roofing systems, a popular choice for architects, builders, and homeowners alike. But what exactly are Bemo Roof Panel Machines, and how do they work? Buckle up, because we’re diving deep into the world of these fascinating machines!

Function of Bemo Roof Panel Machines

At its core, a Bemo Roof Panel Machine is a roll forming machine specifically designed to create interlocking metal panels for roofing applications. Think of it like a high-tech cookie cutter, but instead of sugary treats, it shapes sheets of metal into precise profiles. Here’s a breakdown of the process:

- Feeding the Machine: Coils of sheet metal, typically aluminum or steel, are fed into the machine.

- Roll Forming Magic: The metal sheet is then guided through a series of rollers that progressively bend and shape it into the desired profile. These rollers are engraved with intricate patterns that define the final shape of the panel, including interlocking seams and ribs for added strength.

- Cutting to Length: Once the desired profile is formed, the machine precisely cuts the panel to the specified length.

- Ready for Installation: The finished panels are then stacked and prepared for installation on the roof.

The entire process is automated and remarkably efficient, churning out pre-formed panels at a steady pace. This not only saves time on construction sites but also ensures consistent quality and uniformity in the finished roof.

Benefits of Bemo Roof Panel Machines

Bemo Roof Panel Machines offer several advantages over traditional roofing methods:

- Efficiency: Compared to manually cutting and shaping sheet metal on-site, these machines significantly speed up the roofing installation process.

- Precision: The automated roll forming process guarantees consistent panel profiles, leading to a tighter fit and a more aesthetically pleasing roof.

- Durability: Bemo machines are built to handle various metal gauges, resulting in robust and long-lasting roof panels.

- Versatility: These machines can create a wide range of panel profiles to suit different architectural styles and functional needs.

- Reduced Waste: The precise cutting process minimizes material waste compared to traditional methods.

Types of Bemo Roof Panel Machines

Not all Bemo Roof Panel Machines are created equal. Different models cater to specific needs and offer varying functionalities. Here’s a breakdown of some common types:

- Straight Panel Machines: These machines produce flat panels with interlocking seams on the sides. They are ideal for simple roof designs with straight runs.

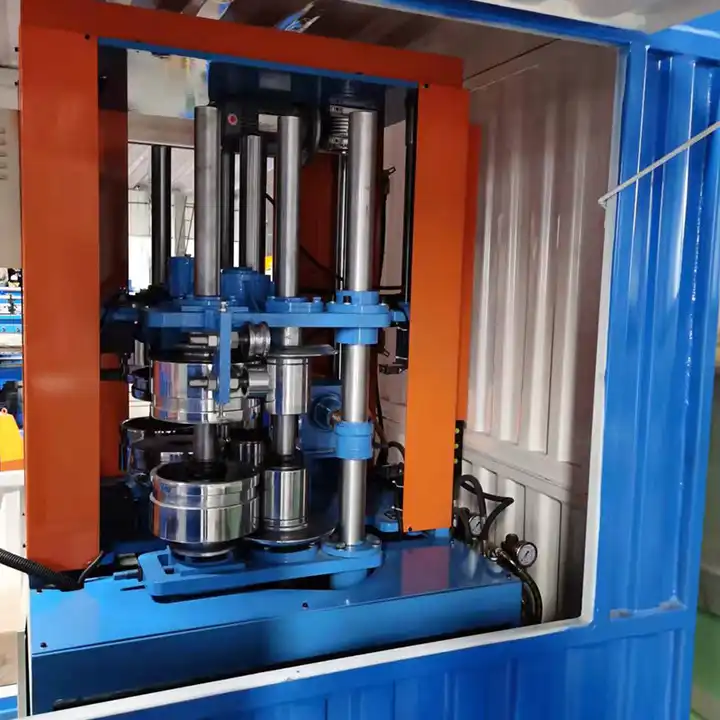

- Tapered Panel Machines: These machines create panels that gradually decrease in width along their length. This is particularly useful for conical or curved roof structures.

- High-Capacity Machines: Designed for large-scale projects, these machines boast faster production speeds and can handle wider coils of metal.

- Customizable Machines: Some manufacturers offer machines that can be configured to produce specific panel profiles or accommodate a wider range of metal thicknesses.

Applications of Bemo Roof Panel Machines

Bemo Roof Panel Machines are a popular choice for a variety of roofing applications, including:

- Commercial Buildings: From office complexes to warehouses, Bemo panels offer a durable, weather-resistant, and aesthetically pleasing roofing solution for commercial structures.

- Residential Buildings: Modern homes often utilize standing seam roofs for their clean lines and architectural appeal. Bemo machines make this option more accessible and efficient.

- Industrial Buildings: These machines can produce heavy-duty panels ideal for withstanding harsh weather conditions and industrial environments.

- Curved Roofs: Tapered panel machines are instrumental in creating unique curved roof designs for architectural statements.

-

Standing Seam Roof Panel Curving Machine

Standing Seam Roof Panel Curving Machine -

Barrel Corrugated Roll Forming Machine

Barrel Corrugated Roll Forming Machine -

Stand Seaming Roof Panel Roll Forming Machine

Stand Seaming Roof Panel Roll Forming Machine -

Downspout Pipe Roll Forming Machine

Downspout Pipe Roll Forming Machine -

Gutter Roll Forming Machine

Gutter Roll Forming Machine -

Trapezoidal Panel Roll Forming Machine

Trapezoidal Panel Roll Forming Machine -

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine -

Double Layer Panel Roll Forming Machine

Double Layer Panel Roll Forming Machine -

Roof Tile Panel Roll Forming Machine

Roof Tile Panel Roll Forming Machine

Advantages and Considerations

While Bemo Roof Panel Machines offer numerous benefits, there are a few points to consider:

- Initial Investment: The cost of purchasing a Bemo Roof Panel Machine can be significant. However, for professional roofers or companies specializing in standing seam roofs, the return on investment can be substantial due to increased efficiency and productivity.

- Technical Expertise: Operating a Bemo Roof Panel Machine requires a certain level of technical knowledge and training to ensure proper setup, operation, and maintenance.

- Material Compatibility: These machines are typically designed to work with specific types and thicknesses of metal. It’s crucial to choose a machine compatible with the desired roofing material.

Finding the Right Bemo Roof Panel Machine

The ideal Bemo Roof Panel Machine depends on your specific needs and project requirements. Here are some factors to consider when making your choice:

- Production Volume: Estimate the volume of panels you anticipate needing for your projects. Higher-capacity machines might be suitable for large-scale contractors, while smaller machines might suffice for individual roofers.

- Panel Profile: Determine the specific panel profile you require for your project. Consider factors like roof pitch, desired aesthetics, and structural needs. Different Bemo machines produce different profiles.

- Metal Compatibility: Ensure the machine you choose is compatible with the type and thickness of metal you plan to use for your roof panels.

- Machine Features: Some Bemo machines offer additional features like automatic stacking or integrated punching for ventilation holes. Consider if these features would benefit your workflow.

- Budget: Bemo Roof Panel Machines range in price depending on their capabilities and production capacity. Set a realistic budget and choose a machine that offers the best value for your needs.

Here’s a helpful analogy: Selecting a Bemo Roof Panel Machine is akin to choosing a power tool. A heavy-duty drill caters to construction professionals tackling demanding projects, while a homeowner might opt for a smaller, more user-friendly drill for occasional DIY tasks. Similarly, the ideal Bemo machine should align with your specific roofing needs and production volume.

Supplier Landscape and Pricing

The good news is that you have options when it comes to Bemo Roof Panel Machines. Here’s an overview of the supplier landscape and pricing considerations:

- Bemo Group: The original developer of Bemo roof panel forming technology, Bemo Group offers a range of high-quality machines known for their precision and durability. Expect these machines to be on the higher end of the pricing spectrum.

- Chinese Manufacturers: Several Chinese manufacturers produce Bemo-compatible machines at a more competitive price point. While these machines might offer good value, it’s crucial to research their reputation, build quality, and after-sales support before making a purchase.

- Used Equipment Market: A pre-owned Bemo Roof Panel Machine can be a cost-effective option for budget-conscious buyers. However, thoroughly inspect the machine’s condition, maintenance history, and availability of spare parts before committing.

Here’s a table summarizing some key considerations for supplier selection and pricing:

| Factor | Description |

|---|---|

| Supplier Reputation | Research the supplier’s track record, customer reviews, and industry standing. |

| Machine Quality | Consider factors like build materials, engineering design, and overall machine robustness. |

| Warranty and Support | Ensure the supplier offers a comprehensive warranty and reliable after-sales support for parts and technical assistance. |

| Price | Compare prices from different suppliers while considering the overall value proposition, including machine capabilities, warranty terms, and ongoing support costs. |

Remember, the cheapest option isn’t always the best. Striking a balance between upfront cost, long-term value, and reliable support is key to making a sound investment.

Beyond the Basics: Advanced Considerations

For those delving deeper into the world of Bemo Roof Panel Machines, here are some advanced considerations:

- Automation Level: Some machines offer a higher degree of automation, reducing manual intervention and increasing production efficiency. This might be beneficial for high-volume projects.

- Integration with Software: Advanced machines might integrate with design software, allowing for seamless conversion of digital designs into roll forming instructions for the machine.

- Sustainability Features: Look for machines with features that minimize energy consumption or utilize recycled materials in their construction.

The Future of Bemo Roof Panel Machines

The Bemo Roof Panel Machine industry is constantly evolving. Here’s a glimpse into what the future might hold:

- Increased Automation: Expect to see even more automation integrated into Bemo machines, further streamlining the production process and minimizing human error.

- Material Innovation: The development of new, lighter, and more sustainable roofing materials might necessitate advancements in Bemo machine technology to accommodate these materials.

- Integration with Building Information Modeling (BIM): Increased integration with BIM software could allow for a more holistic approach to roofing design and fabrication.

In conclusion, Bemo Roof Panel Machines are a powerful tool for shaping the future of metal roofing. By understanding their function, types, and applications, you can make an informed decision when selecting a machine that aligns with your specific needs. As technology continues to evolve, these remarkable machines will undoubtedly play an even greater role in creating beautiful, durable, and sustainable roofs for years to come.

FAQ

Q: What are the benefits of using a Bemo Roof Panel Machine?

A: Bemo Roof Panel Machines offer several advantages, including increased efficiency, improved precision, enhanced durability, design versatility, and reduced material waste.

Q: How much does a Bemo Roof Panel Machine cost?

A: The cost of a Bemo Roof Panel Machine varies depending on several factors, including:

- Brand: Machines from Bemo Group, the original developer, tend to be pricier than those from Chinese manufacturers.

- Capabilities: High-capacity machines with advanced features will carry a higher price tag compared to basic models.

- New vs. Used: Pre-owned machines offer a more budget-friendly option, but thorough inspection and consideration of maintenance history are crucial.

A realistic price range can start around $20,000 for basic, lower-capacity machines from Chinese manufacturers and can reach well over $100,000 for high-end, automated models from Bemo Group.

Q: What factors should I consider when choosing a Bemo Roof Panel Machine?

A: Consider factors like:

- Production Volume: Match the machine’s capacity to your anticipated needs.

- Panel Profile: Ensure the machine can create the specific profile you require.

- Metal Compatibility: Choose a machine compatible with your preferred roofing material.

- Machine Features: Evaluate if additional features like automatic stacking or punching are beneficial.

- Budget: Set a realistic budget and find a machine that offers the best value for your needs.

Q: Where can I find a Bemo Roof Panel Machine?

A: You have several options:

- Bemo Group: The official manufacturer offers high-quality machines.

- Chinese Manufacturers: Several companies offer Bemo-compatible machines at a lower price point.

- Used Equipment Market: Look for pre-owned machines for a more budget-friendly option.

Remember, conducting thorough research on suppliers, machine specifications, and after-sales support is crucial before making a purchase.