The global hospitality industry is constantly evolving, with hotels, resorts, and luxury accommodations striving to create sleek, durable, and aesthetically appealing interiors. To meet this demand, Hotel Furniture Roll Forming Machines have emerged as a game-changer in furniture production, enabling manufacturers to produce high-quality metal furniture components with precision, efficiency, and customization capabilities.

From bed frames and wardrobe structures to decorative wall panels and modular furniture, roll-forming technology is transforming the way hotel furniture is manufactured. In this comprehensive guide, we’ll explore what Hotel Furniture Roll Forming Machines are, their applications, pricing, key features, troubleshooting tips, and why Wuxi Sunway Machinery is leading the industry in furniture roll-forming solutions.

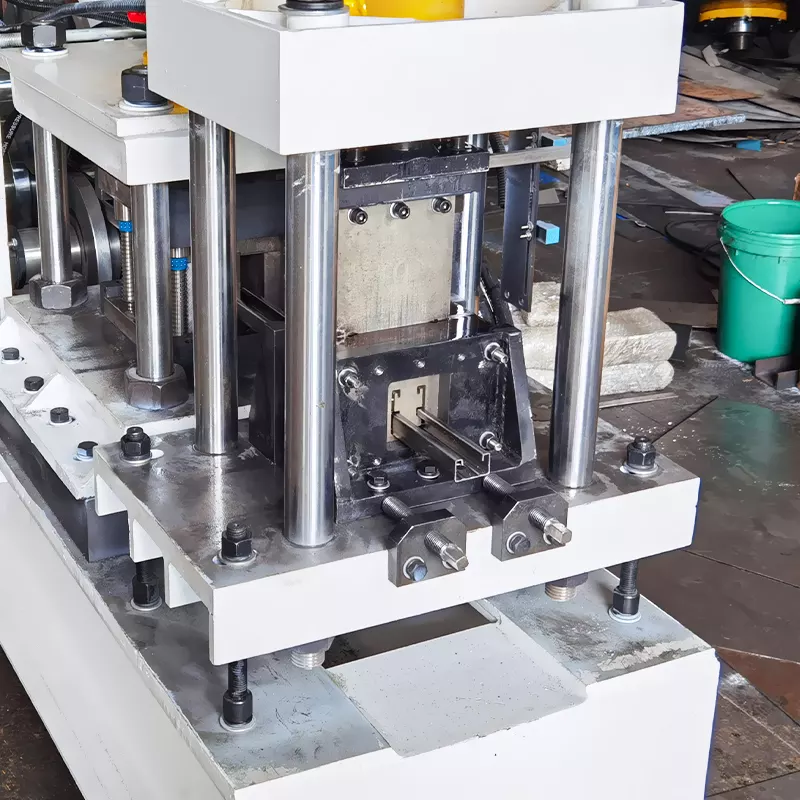

What Are Hotel Furniture Roll Forming Machines?

Hotel Furniture Roll Forming Machines are specialized roll-forming systems designed to manufacture metal components for hotel interiors, furniture, and decorative elements. These machines process stainless steel, aluminum, and coated metals into precise profiles, ensuring that the fabricated components meet the highest durability, aesthetic, and fire-resistant standards required in the hospitality industry.

Key Features of Hotel Furniture Roll Forming Machines

- Custom Profile Designs – Supports the production of bed frames, wardrobe structures, and decorative wall panels.

- Material Versatility – Works with stainless steel, aluminum, galvanized steel, and pre-coated metals.

- High Precision – Ensures consistent dimensions and seamless furniture assembly.

- Decorative and Functional Coatings – Produces panels with fireproof, scratch-resistant, and corrosion-resistant coatings.

- High-Speed Production – Enables the manufacturing of large furniture batches efficiently.

- Automation and IoT Integration – Reduces labor costs and enhances operational efficiency.

Applications of Hotel Furniture Roll Forming Machines

Hotel furniture must meet strict industry regulations for durability, aesthetics, and fire safety. Hotel Furniture Roll Forming Machines play a vital role in producing components for various applications:

1. Metal Bed Frames and Headboards

- Use Case: Producing steel and aluminum bed frames for hotel rooms.

- Why It’s Essential: Ensures lightweight, durable, and corrosion-resistant structures.

2. Wardrobe and Closet Structures

- Use Case: Manufacturing metal wardrobe frames and shelving units.

- Why It’s Beneficial: Provides sturdy, long-lasting storage solutions that withstand heavy usage.

3. Hotel Room Wall Panels and Decorative Elements

- Use Case: Producing decorative metal wall panels and partition systems.

- Why It’s Important: Enhances aesthetic appeal and fireproofing in hotel interiors.

4. Modular Furniture for Lobby and Lounge Areas

- Use Case: Fabricating modular seating, partition systems, and reception desks.

- Why It’s Necessary: Enables quick assembly and flexible space design.

5. Ceiling and Flooring Panels

- Use Case: Roll-forming metal ceiling grids and durable floor panels.

- Why It’s Innovative: Enhances safety, acoustics, and fire resistance.

6. Balcony and Staircase Railings

- Use Case: Producing customized metal railings for hotel balconies and staircases.

- Why It’s Cutting-Edge: Ensures stylish, secure, and corrosion-resistant designs.

Key Features of Wuxi Sunway Hotel Furniture Roll Forming Machines

When it comes to delivering precision, durability, and innovation, Wuxi Sunway Machinery stands out as a leader in roll-forming technology. Their Hotel Furniture Roll Forming Machines are trusted by manufacturers worldwide for high-performance, cost-effective, and customizable furniture production.

1. Advanced Profile Customization

- What It Offers: Machines equipped with advanced tooling for producing furniture frames, panels, and decorative elements.

- Why It’s Critical: Supports a diverse range of hotel interior designs and structural requirements.

2. Material Flexibility

- What It Processes:

- Aluminum – Lightweight and corrosion-resistant.

- Galvanized Steel – Provides strength and durability.

- Pre-Coated Metals – Offers decorative finishes with protective coatings.

- Why It’s Essential: Accommodates various project specifications and aesthetic preferences.

3. High-Speed Production Capabilities

- What It Achieves: Processes up to 50 meters of metal per minute.

- Why It’s Efficient: Meets high-volume production demands while maintaining uniform quality.

4. IoT and Automation Integration

- What It Incorporates: Smart monitoring, remote diagnostics, and predictive maintenance.

- Why It’s Innovative: Enhances operational efficiency and reduces downtime.

5. Fireproof, Scratch-Resistant, and Anti-Corrosion Coatings

- What It Delivers: Machines capable of applying protective coatings during production.

- Why It’s Beneficial: Ensures longevity, safety, and compliance with hospitality standards.

6. Customizable Machine Configurations

- What It Supports: Modular tooling systems for producing a wide variety of hotel furniture profiles.

- Why It’s Flexible: Allows manufacturers to adapt to changing market trends.

Pricing of Hotel Furniture Roll Forming Machines

The cost of a Hotel Furniture Roll Forming Machine varies depending on features, production capacity, and customization options. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Standard Machines | Basic furniture panel and frame production | 200,000–200,000–200,000–500,000 |

| Advanced Machines | High-speed production with decorative coatings | 500,000–500,000–500,000–1,000,000 |

| Customizable Machines | Tailored for unique hotel furniture designs | 1,000,000–1,000,000–1,000,000–2,500,000 |

For detailed pricing and financing options, contact Wuxi Sunway Machinery.

Advantages of Using Hotel Furniture Roll Forming Machines

1. High Production Efficiency

- Enables mass production of hotel furniture components while reducing costs.

2. Aesthetic and Functional Versatility

- Supports decorative, fireproof, and corrosion-resistant furniture designs.

3. Cost Efficiency

- Reduces raw material waste and labor costs, lowering overall production expenses.

4. Precision and Uniformity

- Ensures consistent furniture dimensions for seamless assembly.

5. Compliance with Hospitality Standards

- Meets fire safety, durability, and aesthetic regulations for hotel interiors.

Real-World Success Stories: How Hotel Furniture Roll Forming Machines Are Transforming the Hospitality Industry

From luxury suites to budget-friendly accommodations, Hotel Furniture Roll Forming Machines are playing a crucial role in delivering high-quality, uniform, and aesthetically appealing furniture components. Below are some real-world applications showcasing the impact of these machines.

1. High-End Luxury Hotel in Dubai

Client: A five-star hotel chain specializing in luxury accommodations.

Challenge: Required customized, high-end furniture components with intricate metal designs for headboards, wall panels, and decorative trims.

Solution: Wuxi Sunway Machinery supplied a custom roll-forming machine with precision engraving capabilities for decorative metal panels.

Outcome:

- Produced over 50,000 custom metal furniture pieces in six months.

- Achieved luxury-grade finishes with scratch-resistant coatings.

- Reduced manual fabrication costs by 40%, increasing overall efficiency.

2. Budget Hotel Chain in North America

Client: A large hotel chain offering affordable, standardized room designs.

Challenge: Needed to mass-produce durable bed frames, wardrobe structures, and shelving units while keeping costs low.

Solution: Wuxi Sunway provided a high-speed, automated roll-forming system capable of producing 1000+ bed frames per day.

Outcome:

- Decreased production costs by 30%, making the project more profitable.

- Manufactured over 500,000 furniture components in one year.

- Improved assembly efficiency with precisely dimensioned panels.

3. Boutique Hotel in France

Client: A boutique hotel chain known for artistic, customized interiors.

Challenge: Required unique, decorative metal panels for furniture and wall designs that matched their brand identity.

Solution: Wuxi Sunway designed a flexible roll-forming machine that allowed quick changes in panel patterns and finishes.

Outcome:

- Enabled production of customized furniture on demand.

- Reduced lead times by 50%, accelerating hotel renovations.

- Created visually stunning, high-end furniture components with premium finishes.

4. Resort Chain in Southeast Asia

Client: A tropical resort brand expanding across Thailand, Malaysia, and Indonesia.

Challenge: Needed weather-resistant, corrosion-proof metal furniture for outdoor seating and balcony railings.

Solution: Wuxi Sunway provided a roll-forming machine with anti-corrosion coating integration.

Outcome:

- Produced over 200,000 outdoor furniture components in nine months.

- Ensured long-lasting, rust-proof durability, even in humid climates.

- Reduced maintenance costs by 35%, improving long-term profitability.

Future Trends in Hotel Furniture Manufacturing for 2025

As the hospitality industry evolves, manufacturers are adopting new technologies, materials, and production techniques to stay ahead of the competition. Below are the key trends influencing Hotel Furniture Roll Forming Machines and their applications.

1. Sustainable and Eco-Friendly Furniture Production

- Trend: Increasing demand for recycled metals and sustainable coatings in hotel furniture.

- Impact on Machines: Roll-forming machines optimized for processing eco-friendly materials will dominate the market.

2. Smart Furniture with IoT Integration

- Trend: Hotels are incorporating smart furniture with embedded lighting, sensors, and automation.

- Impact on Machines: Machines will need to accommodate built-in slots and wiring channels for IoT-enabled furniture.

3. Modular and Multi-Functional Furniture

- Trend: Growing popularity of modular, space-saving furniture in hotel rooms.

- Impact on Machines: Machines will focus on producing interlocking, adjustable furniture components.

4. Fireproof and Scratch-Resistant Coatings

- Trend: Hotels require high-durability furniture that meets fire safety and scratch-resistant standards.

- Impact on Machines: Roll-forming machines will incorporate in-line coating systems for fireproofing and durability.

5. Expansion into Emerging Markets

- Trend: Hospitality growth in Asia, the Middle East, and South America is driving demand for affordable, high-quality furniture.

- Impact on Machines: Cost-efficient machines with high production output will cater to these markets.

Innovations in Hotel Furniture Roll Forming Machines for 2025

The next generation of Hotel Furniture Roll Forming Machines is set to revolutionize how hotel interiors and furniture are produced. Below are the latest innovations:

1. AI-Powered Precision Manufacturing

- What It Enables: AI-driven systems automatically adjust machine settings for optimal production.

- Why It’s Revolutionary: Reduces human error, ensuring consistent quality across all furniture components.

2. Multi-Layer Insulated Panel Production

- What It Offers: Machines capable of producing multi-layer panels with integrated insulation for soundproofing.

- Why It’s Valuable: Helps reduce noise pollution in hotel rooms, enhancing the guest experience.

3. Portable On-Site Manufacturing Units

- What It Brings: Machines designed for on-site roll forming, allowing hotel chains to produce furniture panels directly at construction sites.

- Why It’s Game-Changing: Reduces transportation costs and lead times.

4. Advanced Anti-Corrosion and Fireproof Coatings

- What It Integrates: In-line coating systems for applying protective layers during production.

- Why It’s Essential: Extends the lifespan of hotel furniture, making it more durable.

Why Wuxi Sunway Machinery Leads the Hotel Furniture Industry

1. Decades of Expertise

With years of experience, Wuxi Sunway has a proven track record of excellence in furniture roll-forming technology.

2. Cutting-Edge Technology

Incorporates advanced features like IoT, AI-driven quality control, and multi-layer processing into their machines.

3. Customization Excellence

Offers tailored solutions for hotel chains, furniture manufacturers, and interior designers.

4. Global Reach

Trusted by clients across Europe, Asia, the Americas, and Africa, making Wuxi Sunway a global industry leader.

5. Sustainability Commitment

Designs machines that support eco-friendly manufacturing by processing recyclable materials efficiently.

6. Comprehensive Support

Provides consultation, installation, training, and after-sales services for a seamless experience.

Visit their official website to explore their offerings or request a customized solution for your hotel furniture roll-forming needs.

Conclusion: Shaping the Future of Hotel Interior Design with Roll Forming Technology

The hospitality industry is evolving rapidly, and Hotel Furniture Roll Forming Machines are at the heart of this transformation. Whether for luxury hotels, budget chains, or boutique resorts, these cutting-edge machines are enabling faster, safer, and more sustainable furniture production.

Want to enhance your hotel furniture manufacturing capabilities? Partner with Wuxi Sunway Machinery and take your business to the next level.