The automotive industry is a hotbed of innovation, constantly evolving to meet demands for lighter, stronger, and more efficient vehicles. At the heart of this evolution is the role of precision manufacturing, and Auto Parts Roll Forming Machines are leading the charge. These machines enable the production of high-quality, durable, and custom-designed components that are critical to modern automobiles.

In this article, we’ll dive into what auto parts roll forming machines are, their applications, advantages, pricing, automation capabilities, environmental benefits, and why Wuxi Sunway Machinery is a trusted name in the industry. If you’re a manufacturer looking to streamline your production processes or a supplier eyeing the next big leap in automotive technology, this guide will provide the insights you need.

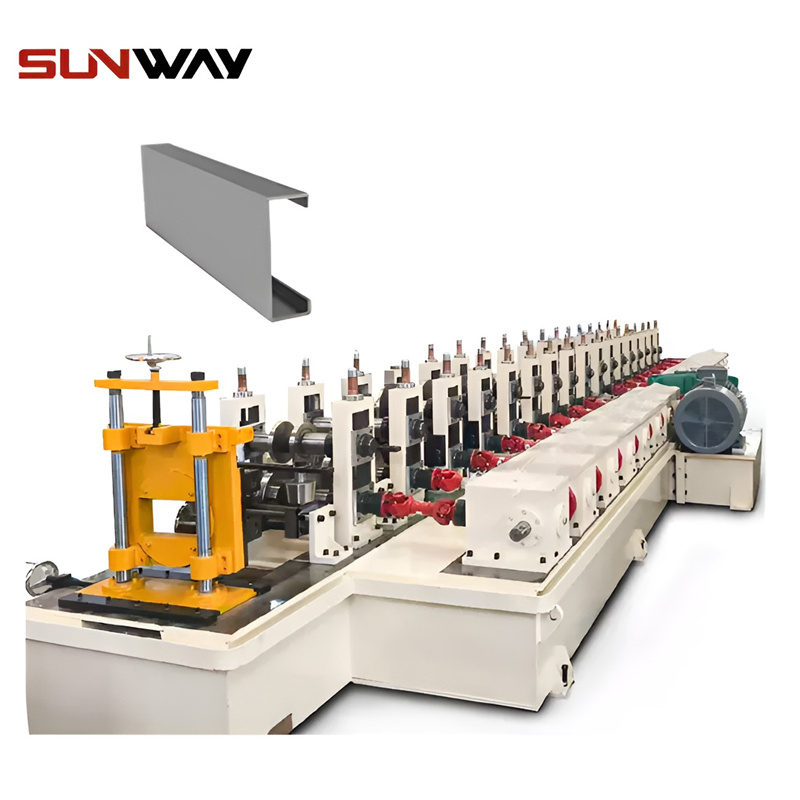

What Are Auto Parts Roll Forming Machines?

Auto Parts Roll Forming Machines are specialized industrial systems designed to shape metal sheets or coils into specific profiles used in automotive manufacturing. These machines leverage a continuous bending process to create components with precision and efficiency, enabling mass production without compromising on quality.

Key Features

- High Precision: Produces components with exact specifications, ensuring compatibility with vehicle designs.

- Material Flexibility: Processes lightweight yet strong materials like aluminum, high-strength steel, and galvanized steel.

- Custom Profiles: Supports diverse designs tailored for different vehicle models and applications.

- High-Speed Production: Meets the demands of large-scale automotive manufacturing.

- Eco-Friendly Practices: Minimizes waste and energy use, aligning with sustainability goals.

Applications of Auto Parts Roll Forming Machines

Auto parts roll forming machines are essential for producing a wide range of components that go into building modern cars, trucks, and other vehicles. Here are the main applications:

1. Automotive Structural Components

- Use Case: Manufacturing structural reinforcements like side impact beams, roof rails, and B-pillars.

- Why It’s Essential: Enhances vehicle safety by creating components that absorb impact and improve structural integrity.

2. Chassis and Frame Parts

- Use Case: Producing chassis components, including crossmembers, rocker panels, and floor reinforcements.

- Why It’s Beneficial: Ensures a lightweight yet strong foundation for vehicles, improving performance and fuel efficiency.

3. Door and Window Frames

- Use Case: Creating precision door frames, window channels, and sealing profiles.

- Why It’s Necessary: Ensures perfect fitment and durability, contributing to the vehicle’s overall aesthetics and functionality.

4. Battery Trays for Electric Vehicles

- Use Case: Manufacturing trays and housings for EV battery systems.

- Why It’s Unique: Supports the growing electric vehicle market by providing lightweight, corrosion-resistant components.

5. Custom Trim and Decorative Parts

- Use Case: Producing custom trim elements, such as moldings, weatherstrips, and accent profiles.

- Why It’s Relevant: Enhances a vehicle’s visual appeal while maintaining durability and precision.

6. Suspension and Support Parts

- Use Case: Crafting suspension reinforcements, brackets, and supports.

- Why It’s Critical: Improves ride quality and vehicle stability by ensuring robust and reliable suspension components.

Why Auto Parts Roll Forming Machines Are Indispensable

The automotive sector is under constant pressure to innovate, reduce costs, and meet sustainability goals. Here’s why Auto Parts Roll Forming Machines are critical to achieving these objectives:

1. Precision Engineering

- Why It’s Vital: Ensures that every component meets tight design tolerances, which is crucial for vehicle safety and performance.

2. Customization for Diverse Models

- Why It’s Beneficial: Allows manufacturers to produce parts tailored to specific vehicle designs, accommodating both standard models and luxury cars.

3. Scalability

- Why It’s Practical: Enables high-speed production to meet the growing demand for automotive components in global markets.

4. Material Efficiency

- Why It’s Economical: Reduces material waste through precise cutting and shaping, lowering overall production costs.

5. Lightweight Design

- Why It’s Relevant: Facilitates the production of lightweight components that improve fuel efficiency and reduce emissions, aligning with industry trends.

6. Sustainability

- Why It’s Important: Supports eco-friendly manufacturing by minimizing energy consumption and enabling the use of recyclable materials.

Key Features of Wuxi Sunway Auto Parts Roll Forming Machines

When it comes to roll-forming technology, Wuxi Sunway Machinery is a global leader. Their Auto Parts Roll Forming Machines are designed to meet the highest standards of precision, efficiency, and innovation. Here’s what sets them apart:

1. Advanced Material Handling

- Supported Materials:

- High-strength steel

- Galvanized steel

- Aluminum

- Stainless steel

- Why It’s Beneficial: Ensures compatibility with lightweight and durable materials essential for modern vehicle manufacturing.

2. Modular Tooling Systems

- What It Offers: Interchangeable tooling for producing multiple component designs on a single machine.

- Why It’s Versatile: Supports diverse manufacturing needs without requiring additional equipment.

3. Integrated Cutting and Punching

- What It Includes: Built-in systems for precision cutting, punching, and notching during the roll-forming process.

- Why It’s Efficient: Reduces production time and ensures ready-to-assemble components.

4. IoT and Automation Integration

- What It Enables: Real-time monitoring, automated adjustments, and predictive maintenance using IoT systems.

- Why It’s Revolutionary:

- Enhances operational efficiency.

- Minimizes downtime and maintenance costs.

5. High-Speed Production

- What It Delivers: Machines capable of producing up to 120 meters of components per minute.

- Why It’s Essential: Keeps up with the high-volume demands of automotive manufacturing.

6. Eco-Friendly Design

- What It Includes: Energy-efficient motors, optimized workflows, and waste reduction systems.

- Why It’s Sustainable: Reduces the environmental impact of auto parts manufacturing.

Pricing of Auto Parts Roll Forming Machines

The cost of an Auto Parts Roll Forming Machine depends on factors like customization, advanced features, and production capacity. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Standard Machines | Basic automotive profiles | 150,000–150,000–150,000–400,000 |

| Advanced Machines | High-speed, integrated cutting and punching systems | 400,000–400,000–400,000–900,000 |

| Fully Customizable Machines | IoT-enabled, modular tooling, eco-friendly features | 900,000–900,000–900,000–2,500,000 |

For specific pricing and financing options, connect with Wuxi Sunway Machinery.

Automation in Auto Parts Roll Forming Machines

Automation is revolutionizing the automotive manufacturing industry, and auto parts roll forming machines are at the forefront of this transformation. By leveraging state-of-the-art technology, these machines deliver superior efficiency and quality.

1. Real-Time Production Monitoring

- What It Tracks: Key metrics such as production speed, material usage, and defect rates.

- Why It’s Valuable: Helps manufacturers optimize workflows and identify inefficiencies.

2. Predictive Maintenance

- What It Enables: IoT sensors monitor wear and tear on components and predict maintenance needs.

- Why It’s Revolutionary:

- Prevents unexpected breakdowns.

- Extends the lifespan of the machine.

3. Automated Adjustments

- What It Offers: Automatically adjusts rollers, cutters, and punches for different materials or designs.

- Why It’s Efficient: Reduces setup time and ensures consistent quality.

4. AI-Powered Quality Control

- What It Detects: Identifies defects in real-time and makes necessary adjustments to maintain quality.

- Why It’s Effective: Reduces waste and enhances customer satisfaction.

5. Remote Control and Diagnostics

- What It Includes: Cloud-based systems for remote monitoring, troubleshooting, and control.

- Why It’s Convenient: Allows operators to oversee production and resolve issues from anywhere.

Environmental Benefits of Auto Parts Roll Forming Machines

Sustainability is a core focus for the automotive industry, and Auto Parts Roll Forming Machines are designed to support eco-friendly practices.

1. Reduced Material Waste

- How It’s Achieved: Precision engineering minimizes scrap material during the manufacturing process.

- Impact: Conserves resources and reduces landfill waste.

2. Energy Efficiency

- How It Works: Equipped with energy-efficient motors and optimized workflows to lower power consumption.

- Impact: Reduces the carbon footprint of automotive manufacturing.

3. Use of Recyclable Materials

- What It Supports: Processes recyclable metals such as aluminum and galvanized steel.

- Impact: Promotes a circular economy and reduces resource extraction.

4. Durable Components

- Why It Matters: Produces high-quality components that are built to last, reducing the need for frequent replacements.

- Impact: Supports sustainable vehicle production by extending part lifespans.

FAQs About Auto Parts Roll Forming Machines

| Question | Answer |

|---|---|

| What materials can these machines process? | High-strength steel, aluminum, galvanized steel, and stainless steel. |

| What is the production speed? | Up to 120 meters per minute, depending on material and profile complexity. |

| Are these machines eco-friendly? | Yes, they include energy-efficient motors and minimize material waste. |

| Can these machines handle custom designs? | Absolutely! Modular tooling supports bespoke profiles for diverse automotive applications. |

| What is the price range for these machines? | Prices range from 150,000to150,000 to 150,000to2,500,000, based on features and customization. |

| Do these machines integrate with IoT systems? | Yes, IoT-enabled features allow real-time monitoring and predictive maintenance. |

Real-World Success Stories: Auto Parts Roll Forming Machines in Action

The transformative capabilities of Auto Parts Roll Forming Machines have enabled manufacturers across the globe to innovate and scale their automotive production lines. Below are some real-world examples of how these machines have revolutionized operations.

1. EV Battery Trays for a Leading Electric Vehicle Manufacturer

Client: A global electric vehicle (EV) brand.

Challenge: The manufacturer required lightweight, corrosion-resistant battery trays for its next-generation EV lineup.

Solution: Wuxi Sunway delivered a roll-forming machine designed to process aluminum and galvanized steel with integrated punching for slots and holes.

Outcome:

- Reduced the weight of battery trays by 20%, improving vehicle range.

- Increased production speed by 30%, meeting tight deadlines for the EV launch.

- Enhanced the company’s reputation as a pioneer in sustainable automotive solutions.

2. Structural Components for a Commercial Truck Manufacturer in North America

Client: A leading truck manufacturer.

Challenge: The company needed heavy-duty chassis components that could withstand high loads and harsh conditions.

Solution: Wuxi Sunway supplied a high-strength steel roll-forming machine with advanced tooling for reinforced profiles.

Outcome:

- Delivered chassis components with superior strength and durability.

- Reduced material waste by 18%, lowering production costs.

- Improved the truck’s performance and reliability, boosting customer satisfaction.

3. Custom Trim Profiles for a Luxury Car Brand in Europe

Client: A luxury automaker specializing in bespoke vehicles.

Challenge: The automaker required custom-designed trim elements to enhance the aesthetics of their premium vehicles.

Solution: Wuxi Sunway provided a roll-forming machine with modular tooling for intricate designs and decorative finishes.

Outcome:

- Enabled the creation of unique, high-quality trim profiles.

- Increased the automaker’s ability to offer personalized design options to its customers.

- Elevated the brand’s market positioning in the luxury automotive segment.

4. Lightweight Suspension Components for an Asian Automotive Supplier

Client: A Tier-1 supplier to multiple global automakers.

Challenge: The supplier needed lightweight yet durable suspension components to improve vehicle fuel efficiency.

Solution: Wuxi Sunway delivered a machine tailored to process high-strength steel with integrated cutting and punching features.

Outcome:

- Reduced component weight by 15%, contributing to better fuel efficiency.

- Enhanced production capacity by 40%, enabling the supplier to meet growing demand.

- Strengthened the supplier’s partnership with leading automakers.

Troubleshooting Common Issues in Auto Parts Roll Forming Machines

Even the most advanced Auto Parts Roll Forming Machines can face operational challenges. Here are some common issues and their solutions to keep your production line running smoothly.

1. Inconsistent Profiles

- Symptoms: Produced components have uneven dimensions or do not meet design specifications.

- Possible Causes:

- Misaligned rollers or worn-out tooling.

- Incorrect material feeding.

- Solution:

- Regularly inspect and realign rollers.

- Ensure proper material feeding by calibrating guides and feeders.

2. Material Jamming

- Symptoms: Material gets stuck in the rollers, halting production.

- Possible Causes:

- Material thickness exceeds the machine’s capacity.

- Debris or foreign objects in the forming area.

- Solution:

- Verify that materials meet the machine’s specifications.

- Clean rollers and guides before each production run.

3. Excessive Tool Wear

- Symptoms: Cutting and punching tools wear out quickly, affecting production quality.

- Possible Causes:

- Low-quality raw materials.

- Improper lubrication of moving parts.

- Solution:

- Use high-grade materials to minimize tool wear.

- Implement a regular maintenance schedule to clean and lubricate components.

4. Machine Vibrations

- Symptoms: Excessive noise and vibrations during operation.

- Possible Causes:

- Loose components or unbalanced rollers.

- Operating the machine beyond its recommended capacity.

- Solution:

- Tighten all components and balance rollers.

- Operate the machine within specified limits.

5. Software Malfunctions

- Symptoms: The control system freezes or fails to execute commands.

- Possible Causes:

- Outdated software or firmware.

- Electrical faults in the control panel.

- Solution:

- Update software to the latest version.

- Inspect and repair any faulty wiring or components in the control panel.

Global Industry Trends for Auto Parts Roll Forming Machines in 2025

The automotive industry is undergoing a paradigm shift, driven by advancements in technology, sustainability, and consumer preferences. Here are the key trends shaping the market for Auto Parts Roll Forming Machines:

1. Transition to Electric Vehicles (EVs)

- Trend: The global shift toward EVs is fueling demand for lightweight and corrosion-resistant components.

- Impact: Roll-forming machines designed for aluminum and other lightweight materials are in high demand.

2. Emphasis on Sustainability

- Trend: Automakers are adopting eco-friendly practices to meet stringent global emissions standards.

- Impact: Machines that minimize waste and enable the use of recyclable materials are becoming industry standards.

3. Rise of Customization

- Trend: Consumers are seeking personalized vehicle designs, driving demand for customized components.

- Impact: Modular roll-forming machines capable of producing bespoke profiles are gaining traction.

4. Smart Factory Integration

- Trend: The adoption of Industry 4.0 technologies is reshaping automotive manufacturing.

- Impact: IoT-enabled roll-forming machines with real-time monitoring and predictive maintenance are leading the charge.

5. Growth in Lightweight Materials

- Trend: The use of high-strength steel, aluminum, and composites is becoming more prevalent to improve fuel efficiency.

- Impact: Machines optimized for these materials are critical for meeting future automotive needs.

Advanced Automation Capabilities in Auto Parts Roll Forming Machines

Automation is the backbone of modern manufacturing, and Auto Parts Roll Forming Machines are no exception. Here’s a look at some cutting-edge automation features:

1. Adaptive Material Handling

- What It Does: Automatically adjusts settings based on the material being processed.

- Why It’s Revolutionary: Reduces setup time and ensures consistent quality across different materials.

2. Intelligent Defect Detection

- What It Includes: AI-powered systems that detect surface defects, misalignments, or dimensional errors in real time.

- Why It’s Effective: Minimizes waste and reduces the need for manual inspections.

3. Multi-Profile Production

- What It Enables: Seamless switching between different component profiles within a single production run.

- Why It’s Convenient: Enhances flexibility and supports diverse manufacturing requirements.

4. Cloud-Based Analytics

- What It Tracks: Production metrics, machine performance, and maintenance schedules.

- Why It’s Valuable: Provides actionable insights to optimize operations and prevent downtime.

Environmental Impact of Auto Parts Roll Forming Machines

Sustainability is a growing focus for the automotive industry, and Auto Parts Roll Forming Machines are designed to align with these goals. Here’s how they contribute to eco-friendly manufacturing:

1. Efficient Material Use

- How It’s Achieved: Precision engineering reduces scrap and ensures optimal use of raw materials.

- Impact: Conserves resources and lowers production costs.

2. Energy Efficiency

- How It Works: Machines are equipped with energy-efficient motors and power-saving features.

- Impact: Reduces energy consumption and the carbon footprint of manufacturing.

3. Support for Recyclable Materials

- What It Enables: Processes materials like aluminum and galvanized steel, which are easily recyclable.

- Impact: Encourages sustainable practices and promotes a circular economy.

4. Long-Lasting Outputs

- Why It Matters: Produces durable automotive components that reduce the need for frequent replacements.

- Impact: Supports sustainable vehicle manufacturing by extending part lifespans.

Why Wuxi Sunway Machinery Leads the Roll Forming Industry

With decades of expertise and a commitment to innovation, Wuxi Sunway Machinery has established itself as a global leader in roll-forming technology. Here’s why they continue to set the benchmark:

- Global Expertise: Trusted by manufacturers across Asia, Europe, the Americas, and beyond.

- Customizable Solutions: Offers tailored machines to meet specific production needs.

- Sustainability Focus: Designs eco-friendly machines that align with global environmental goals.

- Comprehensive Support: Provides end-to-end services, from consultation to after-sales support.

- Proven Innovation: Incorporates cutting-edge technologies like IoT, AI, and modular tooling into their machines.

Explore more about their products on the official website.

FAQs About Auto Parts Roll Forming Machines

| Question | Answer |

|---|---|

| What materials can these machines process? | High-strength steel, aluminum, galvanized steel, and stainless steel. |

| What is the production speed? | Up to 120 meters per minute, depending on material and profile complexity. |

| Are these machines eco-friendly? | Yes, they include energy-efficient motors and minimize material waste. |

| Can these machines handle custom designs? | Absolutely! Modular tooling supports bespoke profiles for diverse automotive applications. |

| What is the price range for these machines? | Prices range from 150,000to150,000 to 150,000to2,500,000, based on features and customization. |

| Do these machines integrate with IoT systems? | Yes, IoT-enabled features allow real-time monitoring and predictive maintenance. |

Conclusion: Accelerating the Automotive Industry with Roll Forming Technology

Auto Parts Roll Forming Machines are shaping the future of automotive manufacturing by enabling precision, efficiency, and sustainability. From lightweight EV components to custom luxury trims, these machines are essential for meeting the demands of a rapidly evolving industry.

Are you ready to drive innovation in your production line? Partner with Wuxi Sunway Machinery and explore their state-of-the-art roll-forming solutions for the automotive sector. Together, let’s accelerate the future of transportation—one component at a time.