You’re probably looking for a roll forming machine for sale to create long rolls of aluminum or plastic, but it’s also essential that you consider the purpose of your machine before looking at any models. If you have a woodworking business, you might be considering getting a rolling mill – these tools can be used to quickly and easily create sheets of wood. Find out which kind of roll forming machine for sale is the best for your company in this blog article.

What is a roll forming machine?

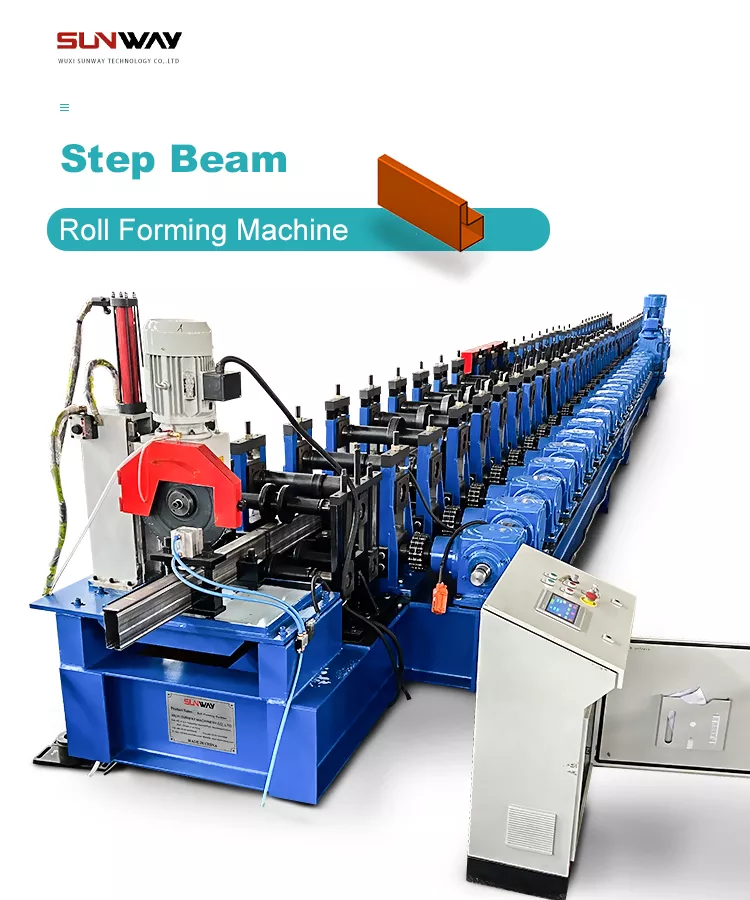

Roll forming machines are used to create custom parts from a variety of materials, including metal, plastic, and composites. The machine uses a rotating die to create the desired shape out of the material being fed into it. Some common features of roll forming machines include automatic feeding, multiple die stations, and precise tolerances.

Types of roll forming machine for sale

Roll forming machines come in a variety of shapes and sizes, so it can be hard to decide which one is the best for your needs. Here are three types of roll forming machine for sale and their respective benefits:

1) Sheet Roll Forming Machine: This machine is perfect for making small objects, such as keys or tags. It’s small size makes it easy to move around, and its simple design means that it doesn’t require a lot of maintenance.

2) Spindle Roll Forming Machine: This type of machine is better suited for making larger objects, such as cars or furniture. It has more capabilities than the sheet roll forming machine, allowing you to make tighter turns and produce more intricate designs.

3) Flexible Plastic Ring Making Machine: This machine is unique because it can create flexible plastic rings out of materials like rubber or plastic. These rings can be used in a variety of applications, from toys to medical devices.

Benefits of roll forming machines

The benefits of roll forming machine for sale include their ability to create complex shapes from thin sheets of metal, plastic, or other materials. They are also versatile and can be used to produce a wide variety of products, such as aircraft parts, car parts, medical devices, and more.

Some of the main benefits of using a roll forming machine include:

- They can create complex shapes from thin sheets of metal or other materials.

- They are versatile and can be used to produce a wide variety of products.

- They are easy to operate and maintenance is minimal.

How do roll forming machines work?

A roll forming machine is a metalworking machinery that uses a cylindrical die to shape metal objects. This type of machine is usually used to make parts such as barrel shapes, profiles, and sheets.

To use a roll forming machine, the user first needs to choose the die they want to use. The die can be made from various materials such as steel, aluminum, or plastic. After selecting the die, the user will need to set up the machine with the correct pistons and gears. Once this is done, they will need to insert the object into the die and start rolling.

The roll forming process works in two stages: vacuum deformation and heat treatment. In vacuum deformation stage, the pressure inside the die causes the metal to deform under stress. This stress Causes heat treatment stage where different types of heating elements are used to change the physical properties of the metal (such as hardness).

-

Downspout Pipe Roll Forming Machine

Downspout Pipe Roll Forming Machine -

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Downpipe Roll Forming Machine

Downpipe Roll Forming Machine -

Cable Ladder Roll Forming Machine

Cable Ladder Roll Forming Machine -

Steel Coil Cut To Length Line Machine

Steel Coil Cut To Length Line Machine -

Steel Coil Cut To Length Line Machine

Steel Coil Cut To Length Line Machine -

Steel Coil Cut To Length Line Machine

Steel Coil Cut To Length Line Machine -

Solar mounting strut channel roll forming machine

Solar mounting strut channel roll forming machine

How do I buy a roll forming machine?

The best roll forming machine for sale are typically designed to produce products such as PVC pipe, carbon fiber sheets and even car parts. The most important factor to consider when purchasing a roll forming machine is the type of material you will be forming. Some machines are specifically designed for PVC pipe, while others can form a variety of materials including carbon fiber.

Once you have determined the type of material you will be working with, the next step is to decide on the size of machine that will fit your needs. The smallest machines can form pipes up to 1 inch in diameter, while the largest machines can form pipes up to 24 inches in diameter. Once you have selected the size of machine, it is important to decide on the speed and torque settings. Most machines come with several speed settings and different torque settings so that you can find one that suits your needs.

Once you have chosen the machine and set it up according to your specifications, it is time to start forming your product! To start, put a sheet of material on the drum or die and feed it through the machine using either manual or electric feeding devices. You then press down on the material with a tool called a die rammer, which forces the material out into a pipe or sheet format. If you want to create intricate details or shapes in your product, you will need to use additional machinery such as rotary cutters or stamping dies.

Conclusion

If you’re in the market for a roll forming machine, you’ll want to take a look at our list of the most suitable ones available. We’ve researched each one carefully and have selected those that we believe offer the best value for your money. Whether you’re looking to produce custom parts or just need an affordable way to manufacture standard items, our products of roll forming machine for sale is sure to meet your needs.