In this article, we will discuss what angle roll forming machine is, the benefits of owning one, and 5 reasons why you should buy one today. We hope that you found our article helpful in deciding whether or not to purchase an angle roll forming machine.

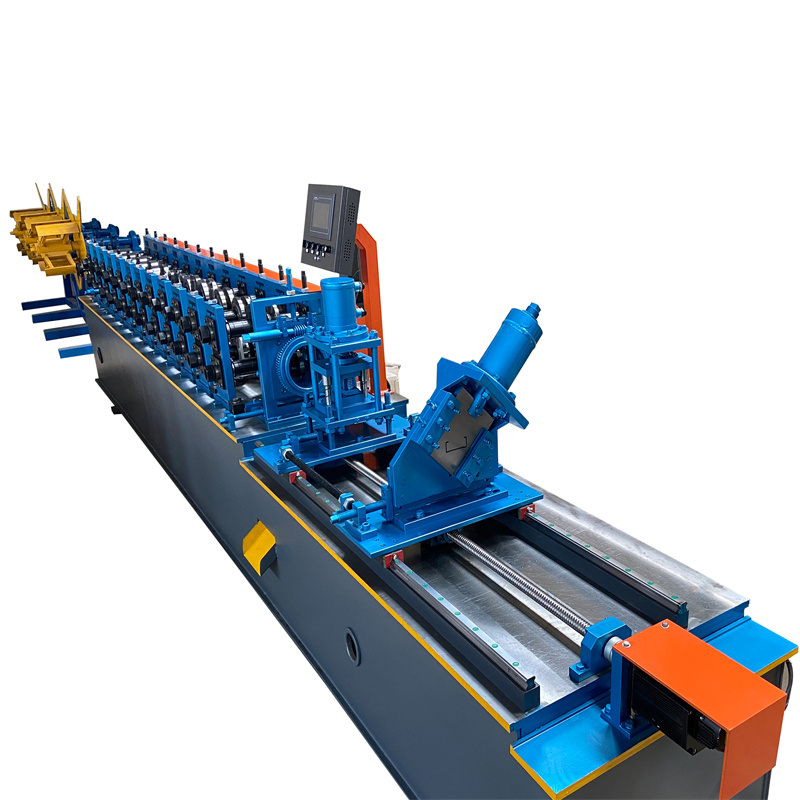

What Is the Angle Roll Forming Machine?

An angle roll forming machine is a type of machine that is used to create metal parts for various purposes. The most common use for an angle roll forming machine is to create metal roofing and siding panels for homes and businesses. These machines can also be used to create metal framing for windows and doors, as well as metal trim for cars and trucks.

Angle roll forming machines are very versatile and can be used to create a wide variety of metal parts. If you are in the market for a new machine, then you should definitely consider an angle roll forming machine.

5 Reasons Why You Should Buy An Angle Roll Forming Machine

If you are in the market for a new angle roll forming machine, there are many reasons why you should buy one. Here are just a few of the benefits to having an angle roll forming machine:

- Increased Productivity – An angle roll forming machine can help increase productivity in your business. With the ability to quickly and easily create custom angles, you will be able to complete projects faster than ever before.

- Cost Savings – An angle roll forming machine can also help save you money. By eliminating the need to outsource your angle needs, you will be able to keep more of your project budget in-house. In addition, with the ability to create angles of any size or shape, you will be able to find the perfect solution for your project without overspending.

- Improved Quality – When you use an angle roll forming machine, you can be sure that the angles you create will be of the highest quality. With precise measurements and consistent results, you can trust that your angles will meet or exceed your expectations every time.

- Greater flexibility – An angle roll forming machine gives you the ability to create custom angles for any project or application. Whether you need a special angle for a difficult installation or want to add a unique touch to your product line, an angle roll forming machine can help make it happen.

- Increased safety – With an angle roll forming machine, there is no need to worry about dangerous power tools or chemicals. With a safe, easy-to use machine, you can create custom angles without putting yourself or your employees at risk.

-

Semi Auto Size Changeable CZ Purlin Roll Forming Machine

Semi Auto Size Changeable CZ Purlin Roll Forming Machine -

Laser Welding Square Pipe Roll Forming Machine

Laser Welding Square Pipe Roll Forming Machine -

Vineyard Post Roll Forming Machine

Vineyard Post Roll Forming Machine -

Scaffolding Plank Roll Forming Machine

Scaffolding Plank Roll Forming Machine -

Light Gauge Steel Roll Forming Machine

Light Gauge Steel Roll Forming Machine -

Auto Size Changeable Sigma Purlin Roll Forming Machine

Auto Size Changeable Sigma Purlin Roll Forming Machine -

Auto Size Changeable C Z Purlin Roll Forming Machine

Auto Size Changeable C Z Purlin Roll Forming Machine -

Auto Size Changeable Z Purlin Roll Forming Machine

Auto Size Changeable Z Purlin Roll Forming Machine -

Auto Size Changeable C U Purlin Roll Forming Machine

Auto Size Changeable C U Purlin Roll Forming Machine

How Do You Use a Roll Forming Machine?

The roll forming machine is a versatile piece of equipment that can be used to create a variety of parts and products. Angle rolls are typically used to form metal sheets into shapes that would be difficult or impossible to create with traditional methods.

There are a number of different ways to use an angle roll forming machine. One common way is to use it to create custom brackets, supports, and other structural elements. Angle rolls can also be used to create panels, doors, and other enclosures. In addition, angle rolls can be used to form curves and bends in metal sheets.

Angle roll forming machines are relatively easy to operate. Most machines come with a set of instructions that will guide you through the process of creating your desired part or product. If you have any questions about how to use your machine, there are usually customer service representatives available who can help you out.

The Cost of a Roll Forming Machine

The roll forming machine is a specialized piece of equipment that is used to create metal parts with a variety of different shapes and sizes. The cost of an angle roll forming machine will vary depending on the specific model and manufacturer. However, you can expect to pay anywhere from $50,000 to $100,000 for a high-quality machine. While this may seem like a lot of money, it is important to remember that an angle roll forming machine is a long-term investment that can save you money in the long run.

How Does It Compare to Other Methods?

If you are considering investing in an angle roll forming machine, you may be wondering how it compares to other methods of forming metal sheets. Here are some key advantages of using a roll forming machine:

- Increased accuracy and repeatability – When you use a roll forming machine, the process is much more accurate and repeatable than other methods such as stamping or die-cutting. This means that you can produce high-quality parts with consistent dimensions.

- Increased speed and efficiency – Roll forming machines can produce parts much faster than other methods, making them ideal for high-volume production runs.

- Reduced material waste – Because the roll forming process is so precise, there is very little material waste when compared to other methods such as stamping or die-cutting.

- Versatility – Roll forming machines can produce parts from a variety of materials including aluminum, steel, and stainless steel. They can also be used to create parts with different shapes and sizes.

Conclusion

If you are looking for an angle roll forming machine, we hope that this article has helped you understand some of the key reasons why you should consider making this purchase. An angle roll forming machine is a versatile and powerful tool that can help streamline your operations and improve your bottom line. We believe that every business can benefit from having one of these machines on-hand, so don’t hesitate to contact us today to learn more about our products.