Roofing roll forming machines are an important part of the roofing process. Roll formers can be more cost efficient than some methods and can help you skip the step of installing felt paper. Find out all the things you need to consider when choosing a roofing roll former in this article so you can get your project started on the right foot.

What is a Roofing Roll Forming Machine?

A roll forming machine is a type of equipment that is used to create long, continuous sheets of metal. These machines are typically used in the manufacturing and construction industries, as they are able to quickly and efficiently create metal products such as roofing panels.

There are many different types of roll forming machines available on the market, each designed for specific applications. When choosing a roofing roll forming machine, it is important to consider the material you will be using, the thickness of the material, and the desired output.

Types of Roofing Roll Forming Machines

A roofing roll forming machine is a type of construction equipment that is used to create metal roofs. There are different types of roofing roll forming machines, each designed for a specific type of roof. The most common types of roofing roll forming machines are:

- Metal Roof Panel Machines: These machines are designed to create metal panels for roofs. They can be used to create panels of any size or shape, and they can be custom-designed to meet the specifications of any project.

- Tile Roof Panel Machines: These machines are designed to create tile panels for roofs. They can be used to create panels of any size or shape, and they can be custom-designed to meet the specifications of any project.

- Shingle Roof Panel Machines: These machines are designed to create shingle panels for roofs. They can be used to create panels of any size or shape, and they can be custom-designed to meet the specifications of any project.

- Slate Roof Panel Machines: These machines are designed to create slate panels for roofs. They can be used to create panels of any size or shape, and they can be custom-designed to meet the specifications of any project.

-

Standing Seam Roof Panel Curving Machine

Standing Seam Roof Panel Curving Machine -

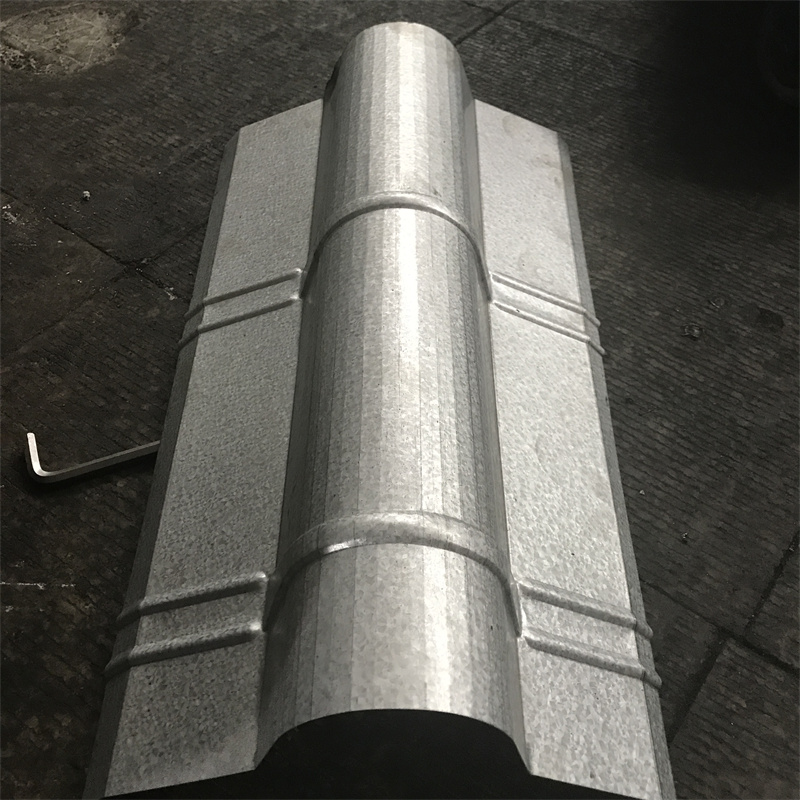

Barrel Corrugated Roll Forming Machine

Barrel Corrugated Roll Forming Machine -

Hydraulic Roof Sheet Curving Machine

Hydraulic Roof Sheet Curving Machine -

Stand Seaming Roof Panel Roll Forming Machine

Stand Seaming Roof Panel Roll Forming Machine -

Downspout Pipe Roll Forming Machine

Downspout Pipe Roll Forming Machine -

Gutter Roll Forming Machine

Gutter Roll Forming Machine -

Trapezoidal Panel Roll Forming Machine

Trapezoidal Panel Roll Forming Machine -

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine -

Double Layer Panel Roll Forming Machine

Double Layer Panel Roll Forming Machine

how to Choose the Right Roofing Roll Forming Machine for Your Needs?

There are a few things you need to take into consideration when choosing a roofing roll forming machine for your needs. The first is the speed at which you need the machine to operate. If you have a high-speed production line, then you will need a machine that can keep up with that pace. Another factor to consider is the size and weight of the coils that you will be using.

Some machines are only designed to handle light-duty coils, while others can accommodate heavier coils. You also need to decide if you want a machine that is manually operated or one that is fully automated. Finally, you need to consider the price of the machine. There are some very expensive machines on the market, but there are also some very affordable options available.

Where to Buy a New or Used Roofing Roll Forming Machine?

When it comes time to purchase your new or used roofing roll forming machine, there are several avenues you can explore to find th est deal. Here are a few tips on where to buy your next roofing roll forming machine:

- Online Auctions: Online auctions are a great way to find a used roofing roll forming machine at a fraction of the cost of a new one. However, it’s important to do your research before bidding on any auction, as there is always the potential for scams.

- Used Machinery Dealers: There are many reputable used machinery dealers who specialize in selling roofing roll forming machines. These dealers typically have a wide selection of machines to choose from and can often provide financing options if needed.

- New Machinery Dealers: If you’re looking for the newest models of roofing roll forming machines, then new machinery dealers is the way to go. These dealers typically have good relationships with manufacturers and can offer competitive pricing on new machines.

- Roofing Contractors: Many roofing contractors have their own roll forming machines that they use for their projects. If you’re looking for a specific model or size of machine, then contacting a local roofing contractor may be your best bet.

Conclusion

There are many factors to consider when choosing a roofing roll forming machine, but if you keep these key points in mind, you’ll be sure to find the perfect one for your needs. First, consider the size and shape of the sheets you’ll be using with the machine. Second, think about the speed at which you need the machine to operate. And finally, make sure to choose a machine that is durable and easy to maintain. With these factors in mind, you’re sure to find the best roofing roll forming machine for your business.