The metal roof roll forming machine is the right choice for your construction project. How do you know? Find out in this blog article and why a metal roof roll forming machine is the right choice for your construction project.

What is the metal roof roll forming machine?

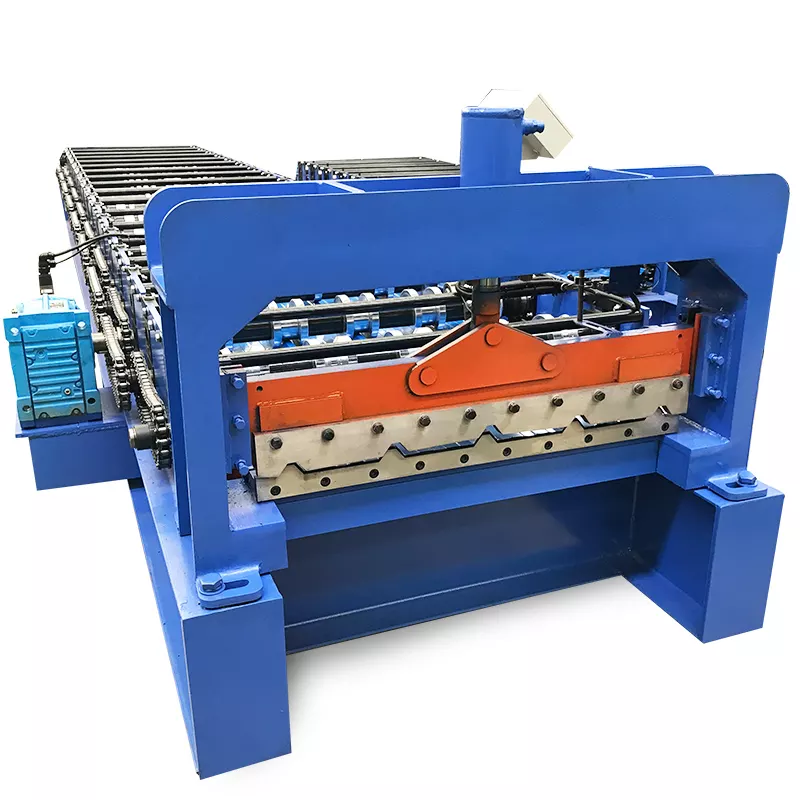

A metal roof roll forming machine is a specialized piece of equipment that helps to create metal roofs. These roofs are becoming increasingly popular due to their durability and aesthetic appeal.

A metal roof roll forming machine for sale can produce roofs that are made from a variety of materials, including aluminum, steel, and copper. The machine works by taking a large sheet of metal and then passing it through a series of rollers that shape it into the desired form. This process is repeated until the entire sheet has been used up.

Benefits of Choosing a metal roof roll forming machine for sale

When it comes to roofs, there are many different materials to choose from. However, metal roofs have become increasingly popular in recent years due to their many benefits. If you’re considering a metal roof for your construction project, here are some of the benefits you can expect:

- Metal roofs are durable and long lasting. With proper care and maintenance, a metal roof can last for decades. This makes them a great investment for any commercial or industrial building.

- Metal roofs are fire resistant. This is an important consideration for any structure, but especially important for those in high fire risk areas.

- Metal roofs are energy efficient. They reflect heat away from the building in summer and help keep heat inside the building in winter. This can lead to lower energy bills year round.

- Metal roofs are low maintenance. Unlike other types of roofs, metal roofs don’t require regular repairs or replacement. This can save you time and money over the life of the roof.

- Metal roofs are environmentally friendly. Most metal roofing is made from recycled materials, and metal roofs can be recycled at the end of their lifespan as well.

-

Standing Seam Roof Panel Curving Machine

Standing Seam Roof Panel Curving Machine -

Barrel Corrugated Roll Forming Machine

Barrel Corrugated Roll Forming Machine -

Hydraulic Roof Sheet Curving Machine

Hydraulic Roof Sheet Curving Machine -

Stand Seaming Roof Panel Roll Forming Machine

Stand Seaming Roof Panel Roll Forming Machine -

Downspout Pipe Roll Forming Machine

Downspout Pipe Roll Forming Machine -

Gutter Roll Forming Machine

Gutter Roll Forming Machine -

Trapezoidal Panel Roll Forming Machine

Trapezoidal Panel Roll Forming Machine -

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine -

Double Layer Panel Roll Forming Machine

Double Layer Panel Roll Forming Machine

How does a metal roof roll forming machine for sale work?

A metal roof roll forming machine for sale is a type of equipment used to create metal roofs. These machines are designed to create metal roofs by rolling and forming metal sheets into the desired shape. Metal roof roll forming machines can be used to create metal roofs for both residential and commercial applications.

Rolling and forming metal sheets into the desired shape is accomplished by passing the sheet through a series of rollers, each of which performs a specific function in the process. The first roller in the machine bends the sheet slightly, while subsequent rollers progressively bend the sheet more and more until it has taken on the desired shape.

The number and type of rollers in a metal roof roll forming machine for sale will vary depending on the specific design of the machine and the type of metal roof being produced. Some machines may have as few as three rollers, while others may have more than twenty.

After passing through the final roller, the metal sheet is cut to length and then sent through a cooling system before being coiled for storage or transport.

Why A Metal Roof Roll Forming Machine Is The Right Choice?

A metal roof roll forming machine for sale is the right choice for your construction project because it is durable, efficient, and cost-effective. Metal roofs are known for their durability, as they can withstand severe weather conditions and last for decades with little to no maintenance. In addition, metal roofs are highly energy-efficient, as they reflect heat away from the building in summer and retain heat in winter. This can help to reduce your energy bills and make your building more sustainable. Finally, metal roof roll forming machines are cost-effective, as they have a long lifespan and require minimal maintenance.

How to Choose the Right Roofing Material?

There are many types of roofing materials on the market today, each with its own set of advantages and disadvantages. When choosing the right roofing material for your construction project, it is important to consider the climate in which the building will be located, the type of structure being built, and your budget.

Metal roofs are an increasingly popular choice for both residential and commercial buildings due to their durability, fire resistance, and energy efficiency. A metal roof roll forming machine can produce panels of various sizes and thicknesses to suit any project.

When deciding if a metal roof is the right choice for your building, consider the following:

-The climate in which the building will be located: Metal roofs are a good choice for both hot and cold climates as they reflect heat away from the building in summer and retain heat in winter.

-The type of structure being built: Metal roofs are suitable for all types of structures, including both new construction and retrofit projects.

-Your budget: Metal roofs are a more expensive option upfront, but they last longer than most other types of roofing materials, so they can save you money in the long run.

Conclusion

A metal roof roll forming machine for sale is the right choice for your construction project because of its many benefits. It is fast and efficient, which saves you time and money. It is also very versatile, so you can use it for a variety of projects. Plus, it is durable and long-lasting, so you know your investment will pay off in the end.