Features

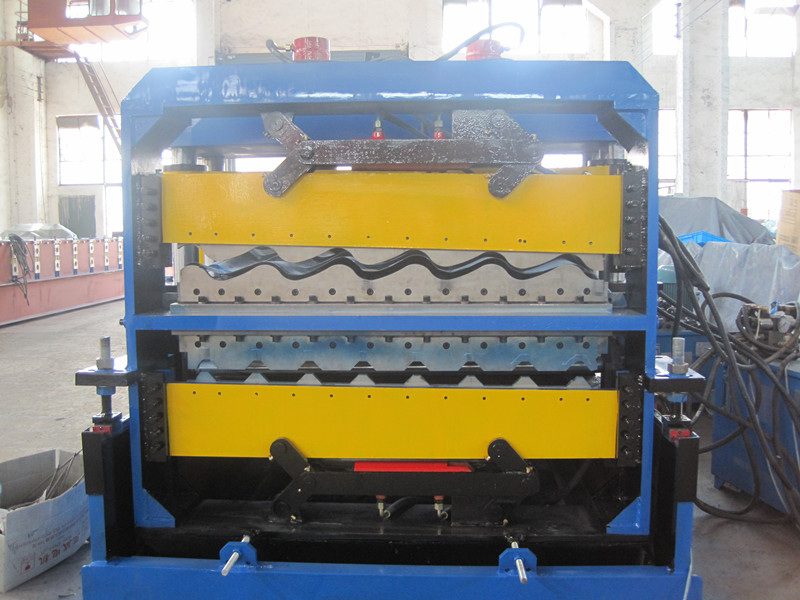

Tile & roof panel double layer machine can produce Tile sheet and roof sheet according to the client’s profile drawings and requirements. The steel trapezoidal sheets are new building materials with various thickness and colors.

Applications

The finished products are used as the roof and walls of gymnasiums, airports, theatres, factories, warehouses, garages, exhibition centers etc.

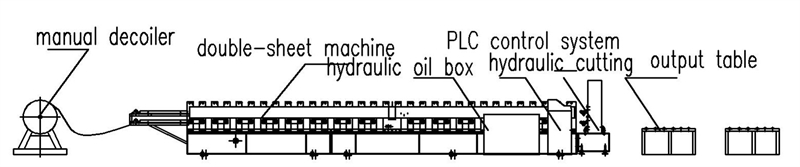

Process Flow

Uncoiler — feeding— roll forming— press & cutting — output

Machine Configurations

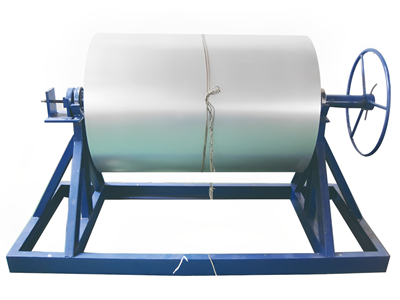

| 1. Uncoiler |

2. Guide feeder

|

| 3. roll former |

4. Hydraulic Press & cutting unit

|

| 5. PLC Control System |

6. Hydraulic station

|

| 7. Output conveyor |

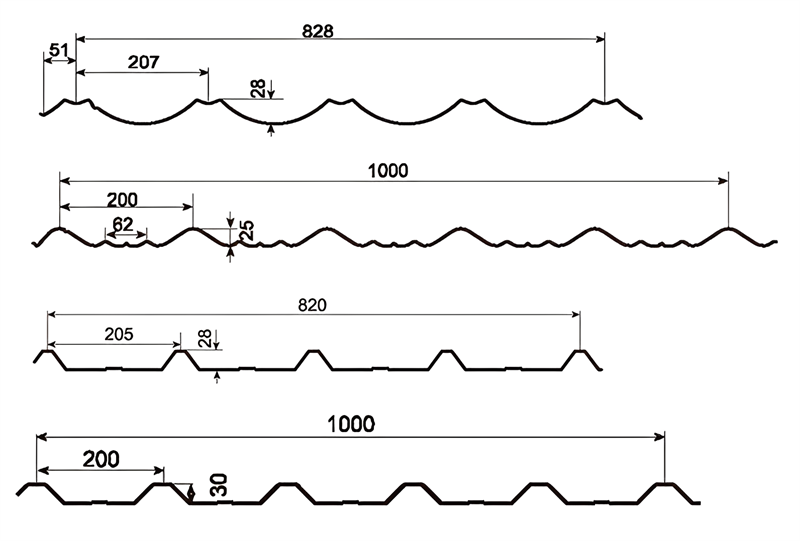

Profile Drawings for Reference

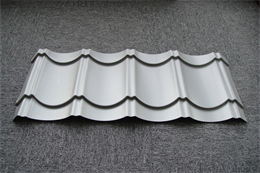

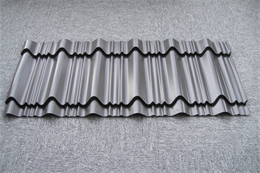

Photos for Reference

What is roof panel roll forming machine?

A roof panel roll forming machine is a specialized industrial machine used in the construction and manufacturing industries. It is designed to produce roof panels, which are commonly used in buildings for their structural integrity and weatherproofing capabilities.

The roll forming machine operates by continuously feeding a flat metal coil into the machine. The coil passes through a series of rollers that gradually shape the metal into the desired profile of the roof panel. These rollers are adjustable and can be customized to create different types of roof panels, such as corrugated panels or standing seam panels.

The roll forming process involves the gradual bending and forming of the metal coil through a series of rollers. Each roller set imparts a specific shape or feature onto the metal as it passes through. The rollers are arranged in a sequential order to achieve the desired profile of the roof panel. The process is highly precise and can produce consistent and accurate roof panels with minimal waste.

Roof panel roll forming machines are typically automated and controlled by computer systems. They can handle high volumes of production and are efficient in creating roof panels with consistent dimensions and quality. The machines often include additional features such as cutting systems to trim the panels to the required lengths and stacking mechanisms to facilitate packaging and transportation.

Overall, roof panel roll forming machines are essential tools in the manufacturing process of roof panels. They enable efficient and precise production, contributing to the construction industry’s ability to quickly and cost-effectively create durable and weather-resistant roofs for various types of buildings.

What is double layer roll forming machine?

A double layer roll forming machine is a type of roll forming machine that is specifically designed to produce two different types of profiles or layers in a single machine. It combines two sets of roll forming systems to create two distinct profiles simultaneously.

The machine consists of two independent roll forming systems, each with its own set of rollers and tooling. These systems are aligned in such a way that they can work together to produce two different profiles or layers in a synchronized manner.

The double layer roll forming machine is often used in applications where a building or structure requires two different types of profiles or layers for its roofing or cladding. For example, it can be used to produce a roof panel with a different profile on the top layer and a different profile on the bottom layer, providing aesthetic appeal and functional advantages.

The machine operates by feeding two separate coils of metal into the respective roll forming systems. Each coil passes through its set of rollers, which gradually shape the metal into the desired profiles. The synchronized operation of the two systems ensures that both layers are formed simultaneously, saving time and increasing efficiency.

Double layer roll forming machines are typically equipped with automation and control systems to ensure precise synchronization between the two roll forming systems. They may also include additional features such as cutting systems, stacking mechanisms, and control panels to facilitate the production process and ensure high-quality output.

Overall, double layer roll forming machines offer a cost-effective and efficient solution for producing two different profiles or layers in a single manufacturing process. They are commonly used in the construction industry for applications where dual-layered roofing or cladding systems are required.

What about double layer roll forming machine price?

The price of a double layer roll forming machine can vary depending on several factors, including the machine’s specifications, complexity, quality, and the manufacturer or supplier from which it is purchased. Other factors that can influence the price include additional features, customization options, and the region or country in which the machine is sold.

As an AI language model, I don’t have real-time access to specific pricing information. However, to get an accurate price for a double layer roll forming machine, it is recommended to contact manufacturers, suppliers, or distributors directly. They can provide you with detailed information about the machine’s specifications, pricing, and any additional costs associated with shipping, installation, or after-sales support.

When considering the price of a double layer roll forming machine, it’s important to balance your budget with the quality and capabilities you require. Cheaper machines may have limitations in terms of precision, durability, or speed, while more expensive machines often offer higher performance, reliability, and additional features.

It’s also worth considering the long-term benefits and return on investment that a high-quality machine can provide. A well-built machine with reliable performance can increase productivity, reduce downtime, and produce consistent and high-quality output, potentially leading to cost savings and improved profitability in the long run.

To get an accurate price and make an informed decision, it is recommended to reach out to multiple suppliers, compare quotes, and evaluate the features, specifications, and after-sales support offered by each. This will help you determine the most suitable option that meets your requirements and budget.

Why A Metal Roof Roll Forming Machine for sale Is The Right Choice For Your Construction Project ?

6 Great Benefits Of A roof panel roll forming machine for sale

Reviews

There are no reviews yet.