The stud and track roll forming machine is a machine which shapes metal into the form of a stud or track. It is most commonly used to shape metal into the form of a stud, but can also be used to shape into a track. This article will explain how it works and the different types of roll forming machines that exist.

What is a stud and track roll forming machine?

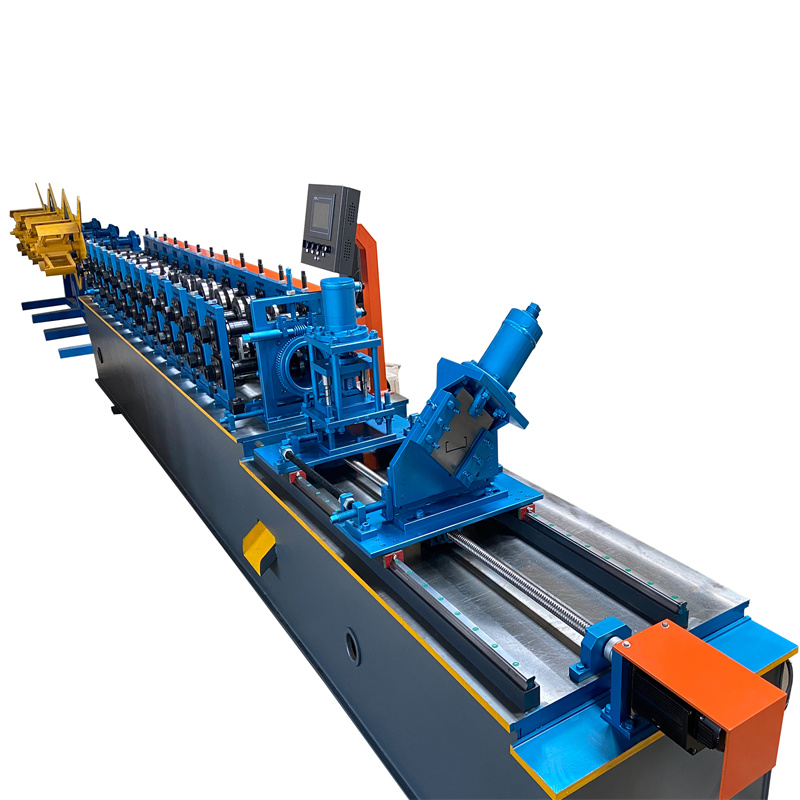

A stud and track roll forming machine is a type of construction equipment that is used to create metal studs and tracks. This machine can be used to create both light-duty and heavy-duty metal framing members. The machine consists of a series of rollers that form the metal into the desired shape. The rolled metal is then cut to length and sent through a cooling process. After the cooling process, the studs and tracks are ready to be installed in a building.

How do stud and track roll forming machines work?

When it comes to stud and track roll forming machines, there are two different types: the automatic and the semiautomatic. Both types of machines work by feeding a coil of metal through a series of dies that progressively shape it into the desired profile.

The main difference between the two types of machines is in how they feed the metal coil. Automatic stud and track roll forming machines have an integrated coil feeding system that automatically moves the coil through the machine as it is being processed. This type of machine is typically used in high-volume production environments where speed and efficiency are critical.

Semiautomatic stud and track roll forming machines, on the other hand, do not have an integrated coil feeding system. Instead, the operator must manually feed the coil through the machine as it is being processed. This type of machine is typically used in lower-volume production environments where speed is not as critical.

Types of stud and track roll forming machines

There are three main types of stud and track roll forming machines: single-stage, two-stage, and three-stage.

Single-stage machines are the most basic and are typically used for smaller projects. They have one set of rollers that forms the metal into the desired shape.

Two-stage machines have two sets of rollers. The first set forms the metal into the rough shape, and the second set finishes it to the desired dimensions. These machines are more versatile than single-stage machines and can be used for larger projects.

Three-stage machines have three sets of rollers. The first two sets form the metal into the rough shape, and the third set finishes it to the desired dimensions. These machines are even more versatile than two-stage machines and can be used for very large projects.

Things to consider when investing a stud and track roll forming machine

There are a few key considerations to make when deciding whether or not to invest in a stud and track roll forming machine for your manufacturing business. The first is the cost of the machine itself. While stud and track roll forming machines are generally more expensive than traditional machines, they offer a number of benefits that may make them worth the investment.

The second consideration is the volume of production you plan to do. If you only plan on producing a small amount of product, then a stud and track roll forming machine may not be the best option. However, if you anticipate needing to produce large quantities of product, then a stud and track roll forming machine can help you save time and money in the long run.

Finally, you’ll need to consider the specific needs of your business when deciding whether or not to invest in a stud and track roll forming machine. If you have unique requirements that can’t be met by traditional machines, then a stud and track roll forming machine may be the best option for you.

Advantages and Disadvantages of a Stud And Track Roll Forming Machine

There are both advantages and disadvantages to using a stud and track roll forming machine. One advantage is that it is a very fast way to create metal studs for use in construction projects. The machine can quickly create long lengths of studs that are then cut to size as needed. This can save a lot of time compared to traditional methods of creating metal studs.

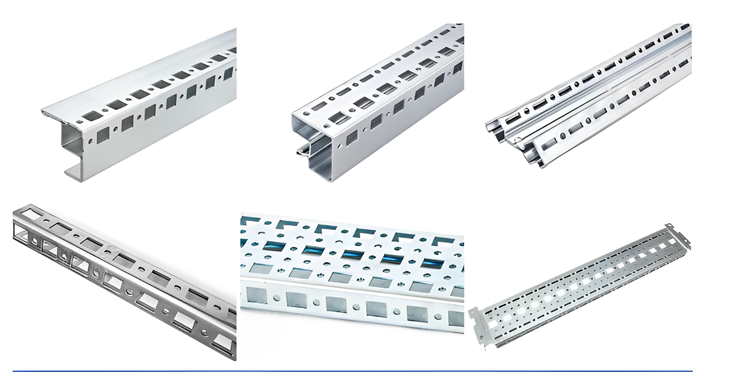

Another advantage is that the machine can be used to create different sizes and shapes of studs. This flexibility can be helpful when working on projects that require non-standard sizes or shapes of metal studs.

A disadvantage of using a stud and track roll forming machine is that it can be difficult to change the size or shape of the metal studs once they have been created. If you need to make a change, it is often necessary to start over from the beginning. This can waste time and materials, and cause frustration for those working on the project.

Conclusion

A stud and track roll forming machine is a versatile tool that can be used to create a variety of metal products. This type of machine is often used in the construction industry to create metal studs, tracks, and other components. Stud and track roll forming machines are available in a variety of sizes and can be customized to meet the specific needs of your business. If you are in the market for a stud and track roll forming machine, be sure to shop around to find the best possible deal.