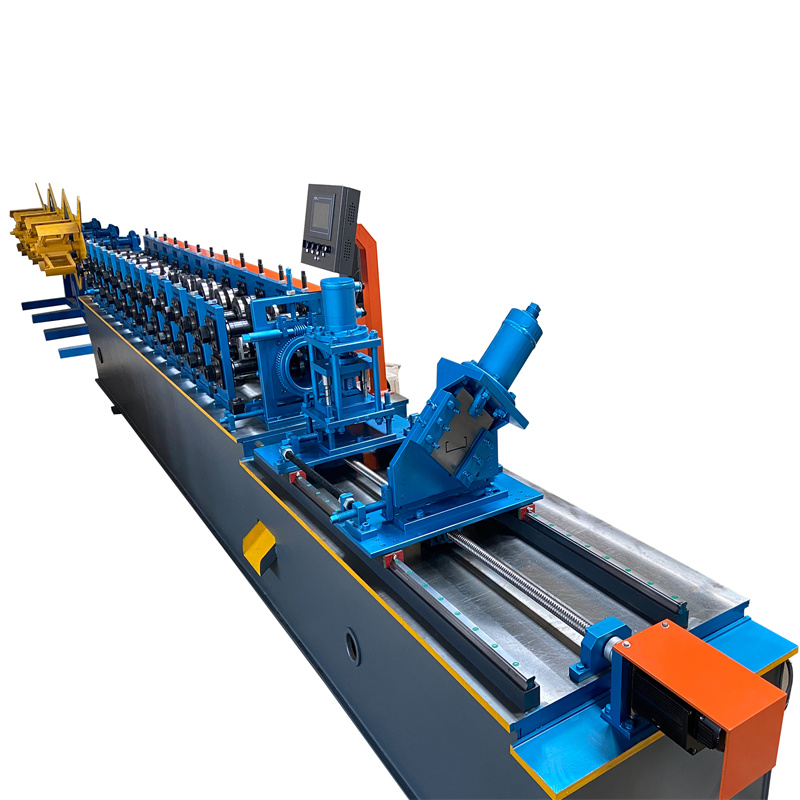

The stud and track roll forming machine is a type of metalworking machinery used to produce studs, rails, and other shapes. This article is going to look at what a stud and track roll forming machine does, why it does it, how it does it and why you would want one.

What is a Stud and Track Roll Forming Machine?

A stud and track roll forming machine is a specialized type of roll forming machine that is used to create metal studs and tracks. These machines are typically used in the construction industry to create metal framing for walls and ceilings.

Stud and track roll forming machines are very versatile and can be used to create a variety of different shapes and sizes of studs and tracks. Typically, these machines will have a variety of different die sets that can be swapped out to create different shapes. This allows the user to create custom shapes and sizes that are not possible with other types of machines.

Roll forming machines are very fast and efficient, which makes them perfect for use in the construction industry. They can quickly produce large quantities of studs and tracks, which is essential for large construction projects.

Types of Stud and Track Roll Forming Machines

There are three types of stud and track roll forming machines: single-web, double-web, and multi-web.

Single-web machines are the most basic type of machine and can only form one web at a time. This type of machine is typically used for small projects or for prototyping.

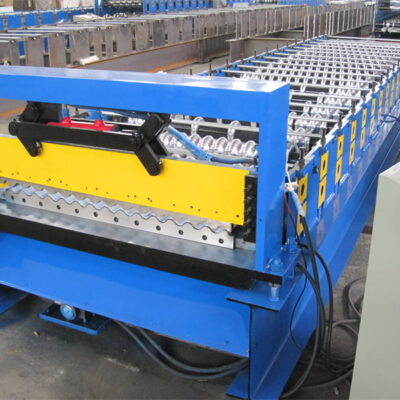

Double-web machines can form two webs at a time, which makes them faster than single-web machines. These machines are typically used for larger projects.

Multi-web machines are the most advanced type of machine and can form multiple webs at a time. These machines are typically used for large projects or for mass production.

-

Gutter Roll Forming Machine

Gutter Roll Forming Machine -

Trapezoidal Panel Roll Forming Machine

Trapezoidal Panel Roll Forming Machine -

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine -

Roof Tile Panel Roll Forming Machine

Roof Tile Panel Roll Forming Machine -

Ridge Cap roll forming machine

Ridge Cap roll forming machine -

L Angle roll forming machine

L Angle roll forming machine -

Trapezoidal panel roll forming machine

Trapezoidal panel roll forming machine -

Roof Panel Double Layer Machine丨Tile &

Roof Panel Double Layer Machine丨Tile & -

Roof Tile Roll Forming Machine

Roof Tile Roll Forming Machine

How a Stud and Track Roll Forming Machine Works?

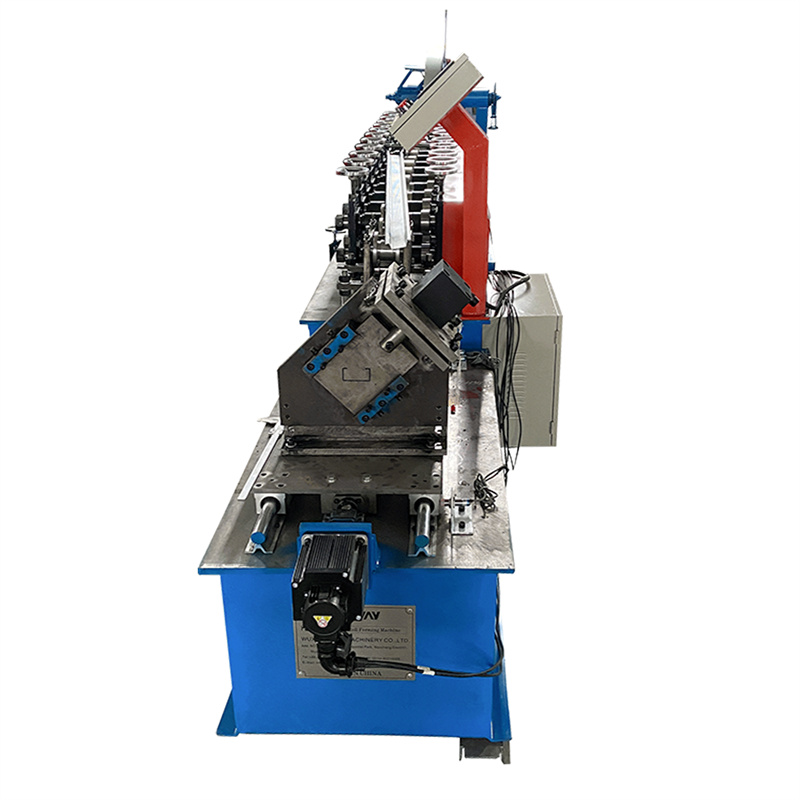

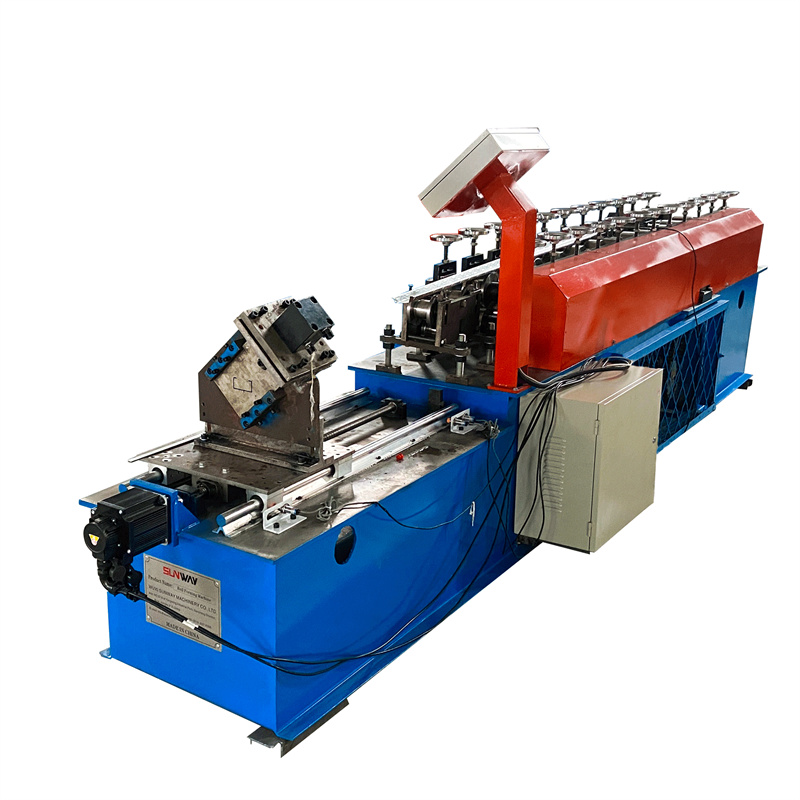

When it comes to stud and track roll forming machines, there are a few key things to know about how they work. First and foremost, these machines are designed to create metal framing components for walls, ceilings, and floors. In order to do this, the machine uses a series of rollers that press the metal into the desired shape.

The first step in the process is known as pre-punching. This is where the machine punches holes into the metal so that it can be properly formed. Next, the metal is fed through a series of rollers that gradually shape it into the desired shape. Finally, the post-punching process trim off any excess metal and ensure that all of the holes are properly aligned.

Benefits of Using A Stud and Track Roll Forming Machine

When it comes to stud and track roll forming machines, there are many benefits that make them a worthwhile investment for any business. For one, these machines are very efficient in terms of production. They can produce large quantities of products in a relatively short amount of time. Additionally, they require very little labor to operate, which can help to keep costs down.

Another benefit of using a stud and track roll forming machine is the fact that they produce consistent results. Every product that comes off the line will be of the same high quality, which is essential for meeting customer expectations. Additionally, this consistency can help to reduce waste and rework, as well as improve overall efficiency.

Finally, stud and track roll forming machines are highly versatile. They can be used to create a variety of different products, from simple parts to complex assemblies. This versatility means that businesses can use them to meet a wide range of needs, ensuring that they always have the right solution on hand.

How to Inspect a Stud and Track Roll Forming Machine?

A stud and track roll forming machine is a type of construction equipment that is used to create metal framing for walls. The studs are the vertical members that provide support for the wall, while the tracks are the horizontal members that provide stability.

There are a few things that you should inspect before you purchase a stud and track roll forming machine:

- The quality of the metal components – You want to make sure that the machine is made with high-quality metal components. This will ensure that it is durable and will last for many years.

- The size of the machine – You need to make sure that the machine is the right size for your needs. If you are planning on creating large walls, then you will need a larger machine.

- The price – You want to make sure that you are getting a good deal on the machine. There is no need to overspend on something that you may not use very often.

Conclusion

A stud and track roll forming machine is a versatile piece of equipment that can be used to create a variety of different building materials. If you are in the construction industry, or if you are looking for a way to make your own building materials, then this type of machine may be right for you. With a stud and track roll forming machine, you can create strong and durable materials that will last for years to come.