The cable tray roll forming machine prices change a lot, but there are some important factors that can affect the price. In this article, I will talk about what those factors are and why they’re important to consider before purchasing the cable roll forming machine you need for your job.

What is a Cable Tray Roll Forming Machine?

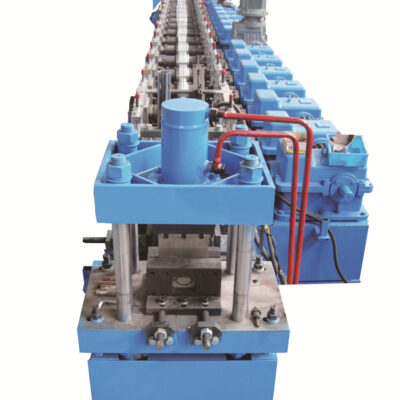

A cable tray roll forming machine is a type of construction equipment that is used to create metal trays that are used to support and route cables and wires. This type of machine is typically used in commercial and industrial settings, as well as in some residential applications. The price of a cable tray roll forming machine can vary depending on the size and features of the machine.

Benefits of Using a Cable Tray Roll Forming Machine

If you are thinking about investing in a cable tray roll forming machine, you may be wondering if it is worth the cable tray roll forming machine price. Here are some of the benefits of using a cable tray roll forming machine:

- Increased productivity – A cable tray roll forming machine can help to increase productivity as it can automate the process of creating cable trays. This means that you will be able to produce more trays in a shorter period of time, which can be beneficial if you have a high demand for them.

- Reduced labor costs – As well as increasing productivity, using a cable tray roll forming machine can also help to reduce labor costs. This is because you will not need to hire as many staff members to operate the machine and create the trays.

- Improved accuracy – When you use a cable tray roll forming machine, you can improve the accuracy of the trays that are produced. This is because the machine can create trays with consistent dimensions and there is less chance for human error.

- Flexibility – A cable tray roll forming machine offers flexibility as you can change the size and shape of the trays that are produced. This means that you can create custom-sized trays to suit your specific needs.

- Increased safety – Using a cable tray roll forming machine can also help to improve safety in your workplace as there is less need for manual handling of materials. This reduces the risk of injuries occurring during the manufacturing process.

-

Vineyard Post Roll Forming Machine

Vineyard Post Roll Forming Machine -

Light Gauge Steel Roll Forming Machine

Light Gauge Steel Roll Forming Machine -

Auto Size Changeable Sigma Purlin Roll Forming Machine

Auto Size Changeable Sigma Purlin Roll Forming Machine -

Auto Size Changeable Z Purlin Roll Forming Machine

Auto Size Changeable Z Purlin Roll Forming Machine -

Full automatic quick-change C Z purlin roll forming machine

Full automatic quick-change C Z purlin roll forming machine -

Vineyards Post Roll Forming Machine

Vineyards Post Roll Forming Machine -

Omega Purlin Roll Forming Machine

Omega Purlin Roll Forming Machine -

L Angle roll forming machine

L Angle roll forming machine -

Keel Steel Roll Forming Machine

Keel Steel Roll Forming Machine

the cable tray roll forming machine price

Cable tray roll forming machines are not cheap. They range in price from around $30,000 to over $100,000. The cable tray roll forming machine price depends on the size and capabilities of the machine.

The cable tray roll forming machine price is an important consideration when deciding whether or not to purchase one. The price is a major factor in the decision making process because it will have a direct impact on the profitability of the business.

A cable tray roll forming machine can be a great investment for a business that uses it frequently. It can save time and money by reducing the amount of labor required to produce cable trays. The machine can also increase the quality of the product and improve customer satisfaction.

When deciding whether or not to purchase a cable tray roll forming machine, the price should be just one of many factors considered. The benefits of owning a machine should be weighed against the initial cost to determine if it is the right decision for the business.

What to Consider When Buying a Cable Tray Roll Forming Machine?

When you are in the market for a new cable tray roll forming machine, there are several factors that you need to take into account in order to ensure that you are getting the best possible machine for your money. Here are a few things to keep in mind when shopping for a new cable tray roll forming machine:

- The cable tray roll forming machine price: Obviously, the price of the machine is going to be one of the most important factors that you need to consider when purchasing a new one. You want to make sure that you get the best possible value for your money, so be sure to compare prices from different manufacturers before making your final decision.

- The features of the machine: Another important factor to consider is the features that each machine offers. Some machines may have more or less features than others, so be sure to compare and contrast what each machine has to offer before making your purchase.

- The warranty: Finally, be sure to check out the warranty that each manufacturer offers on their machines. This will protect you in case anything goes wrong with the machine after you purchase it and can save you a lot of money down the road if something does go wrong.

Conclusion

As you can see, the cable tray roll forming machine price is very important. Not only does it affect your bottom line, but it also affects the quality of your product. When you are looking for a machine, make sure to take the time to find one that fits your budget and offers the features and benefits that you need.