Trim roll forming is a metalworking process that forms metal coils into customized profiles with trim cuts. Trim roll forming machines are used to create trim profiles for various applications like building construction, infrastructure, transportation, packaging, and more. This comprehensive guide provides a detailed overview of trim roll forming machine types, main components, technical specifications, applications, advantages, and more.

Overview of Trim Roll Forming

Trim roll forming is a specialized sheet metal fabrication process used to form metal coil stock into customized trim profiles. It combines conventional roll forming with additional trim cutting stations integrated into the line.

Roll forming shapes flat sheet metal stock into profiles by progressively bending the material through consecutive pairs of contoured rolls. Trim roll forming takes this a step further by cutting the edges and creating finished parts with tight tolerances.

The main advantages of trim roll forming are:

- High production rates and low cost per unit compared to other cutting methods

- Flexibility to create customized and complex trim shapes

- Consistent quality and dimensional accuracy better than +/- 0.5 mm

- Minimal scrap waste since trim cuts are made in-line

- Applicable to a wide range of metals like steel, aluminum, copper, brass

Trim roll forming machines are available in different configurations to produce straight or coiled profiles at rates over 100 meters per minute.

The addition of trimming and slitting stations allows creating finished parts without any secondary operations. This makes trim roll forming ideal for high-volume production of metal trim parts used in construction, infrastructure, transportation, packaging, appliance manufacturing and more.

Types of Trim Roll Forming Machines

Trim roll forming machines can be categorized based on production line configuration, number of forming stations, type of cutting method and profile shape capabilities:

Based on Production Line

- In-line machines: All forming and cutting operations are integrated into one continuous production line. This allows higher outputs with easier part transfer.

- Near-line machines: Forming line is separated from the cutting line. Formed profiles are manually or automatically transferred to the trim line. Provides more flexibility for profile shapes.

- Off-line machines: Forming and trimming are done on completely independent lines in separate areas. Lower output but allows forming standard profiles and custom trimming.

Based on Forming Stations

- Fixed cut-length machines: Cut profile to predefined lengths after forming. Used for high-volume production of standard length parts.

- Variable length machines: Cut profiles on demand to any length within machine capacity. Preferred for low to medium volumes.

Based on Cutting Method

- Punching: Hydraulic or servo-electric punches make holes or notches at preset positions along the profile. Allows extensive customization.

- Shearing: Rotary flying cutters slice profiles at an angle to required length. Faster than punching but with shape limitations.

- Sawing: Circular saw blades cut profiles perpendicular to length. Produces quality trim edges but slower than shear trimming.

- Laser cutting: A laser beam makes trim cuts by melting metal locally. Allows complex contours without dies but has lower throughput.

Based on Profile Shape Capabilities

- Fixed profile: Dedicated roll sets produce the same pre-designed profile repeatedly in high volumes. Lower cost, faster changeovers.

- Adjustable profile: Roll sets have some flexibility to adjust dimensions and create a limited range of similar profiles.

- Universal profile: Fully modular forming stations with quick change tooling allow producing any custom profile within machine capacity. Most flexible but higher cost.

Main Components of Trim Roll Forming Lines

Trim roll forming lines comprise feeding equipment, forming stations, cutting zones, and exit conveyors.

The main components are:

- Decoiler: Feeds flat sheet metal coil stock into the roll former. Includes decoiler mandrel, coil car, threader, straightener, and feeder.

- Forming stations: Progressively bend and shape the strip through consecutive roll stands. Contains top and bottom rolls, housings, gearing, drive, controls.

- Punching and cutting zone: Punch, shear or saw profiling tools make trim cuts to the formed section. Contains cutters, strippers, tool holders, controls.

- Exit conveyor: Transports finished trim parts out of the system. Can include part counting, stacking, bundling equipment.

- Safety equipment: Light curtains, guarding, interlocks ensure operator safety during automated production.

- Controls: PLC automates and monitors line speed, feeds, forms, cuts, exit to optimize production. HMI allows monitoring and parameter changes.

Other components like loop controls, straigteners, lubrication systems support quality high-speed production on trim roll forming machines.

Typical Specifications of Trim Roll Forming Machines

Trim roll formers are available in a wide range of sizes and specifications to match production requirements:

| Specification | Typical Values |

|---|---|

| Line speed | 10 – 120 m/min |

| Strip width capacity | 50 – 2100 mm |

| Strip thickness range | 0.3 – 4 mm |

| Min. profile length | 300 mm |

| Max. profile length | Unlimited with cut-to-length |

| Length tolerance | +/- 1 mm |

| Hole punching tolerance | +/- 0.5 mm |

| Hole size range | 8 – 100 mm dia. |

| Installed power | 15 – 150 kW |

| Noise level | <85 dB |

| Production environment | 10 – 40°C, <90% humidity |

Machines can be supplied in standard designs or custom engineered to specification. Capacities up to 2500 mm width and 6 mm thickness are possible for specialty applications.

Applications of Trim Roll Formed Profiles

Trim roll forming allows cost-efficient mass production of finished metal trim parts. Typical applications include:

Building and Construction

- Window and door frames

- Curtain walling, cladding, façades

- Roofing and flashing

- Interior partition frames

- Lighting troffers, downlighters

- Decorative molding and trim

- Balustrades, handrails

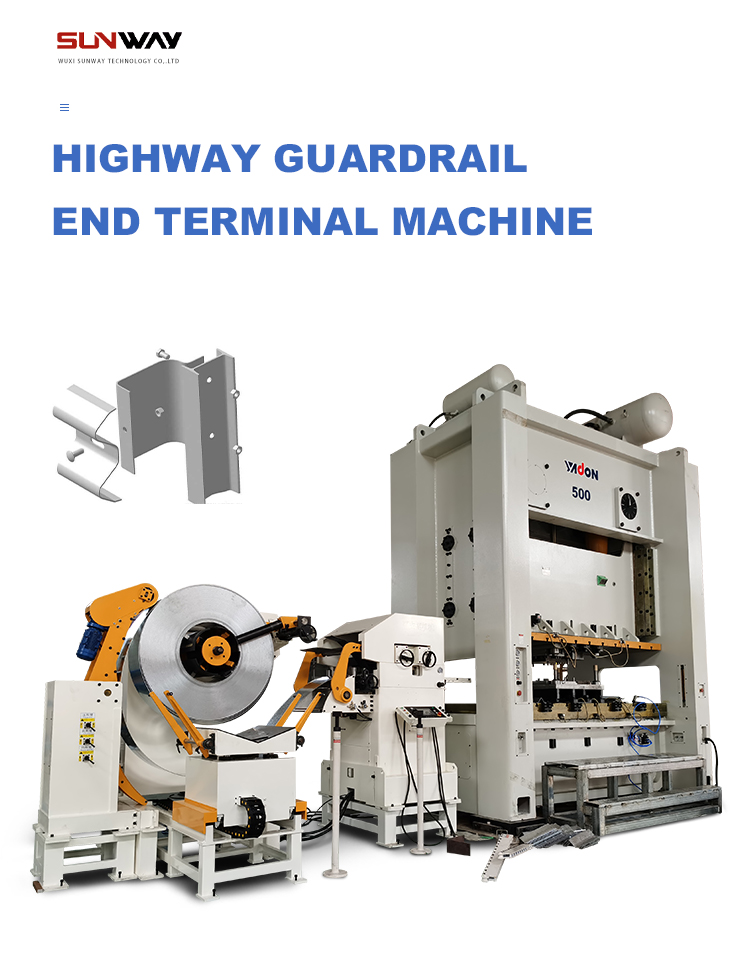

Infrastructure and Transportation

- Road barrier strips

- Crash barriers

- Rail coach panels

- Truck and trailer panels

- Shipbuilding panels

Storage, Racking and Shelving

- Upright columns

- Shelf support braces

- Cross beams

- Gondola shelving

- Decorative support trims

Furniture

- Desk and cabinet frames

- Drawer channels and runners

- Chair and table legs

- Decorative trims

Electrical and Appliances

- Motor and pump housings

- Electrical enclosures and chassis

- Control panels

- Refrigerator liners

- Oven and AC ducts

- Drum and cylinder cladding

Other Applications

- Signage and displays

- Playground equipment

- Agricultural equipment

- Automotive components -defense applications

Nearly any application requiring linear trim profiles can benefit from trim roll forming for consistent quality at high outputs.

Benefits and Advantages of Trim Roll Forming

Some of the main benefits offered by trim roll forming machines are:

- High production speed – Up to 100+ meters per minute

- Low cost – High volumes reduce cost per piece significantly

- Material savings – Low scrap loss compared to other cutting methods

- Flexibility – Various profiles possible from same line

- Customization – Unique shapes achievable via tooling design

- Consistency -parametric control of forming guarantees uniformity

- Automation – 24/7 untended production after setup

- Simplicity – Coils to finished parts in one process

- Quality – Accuracy better than 1 mm on all features

- Scalability – Lines available from 1 m up to 3 m width

- Reliability – Robust industrial construction for heavy duty operation

When high volumes of precision metal trim parts are needed, trim roll forming provides an efficient and cost-effective fabrication solution.

Limitations of Trim Roll Forming

While offering many benefits, trim roll forming also has some limitations:

- High initial tooling cost – Dies, punches and custom roll sets require upfront investment

- Setup time – Tool changes may take several hours for profile changeovers

- Repeat orders – Best suited for continuous high-volume production, not prototypes or small batches

- Shape constraints – Extensive bending and hemming may exceed roll former capacity

- Thickness limits – Typically 0.5 to 6 mm strip thickness range

- Material options – Mainly carbon steel, aluminum and stainless steel

- Secondary operations – May need additional steps like welding, hardware insertion, painting

- Precision limits – Tolerances around ±0.5 mm, not for fine precision parts

For short run or highly complex components, other processes like CNC punching, laser/waterjet cutting may be more suitable.

Step-by-Step Process of Trim Roll Forming

A typical trim roll forming process consists of:

1. Decoiling

- Sheet metal coils loaded onto powered decoiler

- Threading strip through the roll former

- Using loop control and straightener for stable unwinding

2. Feeding

- Feed rolls pull strip through stations at set speed

- Servo feed motors synchronized to roll forming

- Accumulator tower stabilizes material flow

3. Roll forming

- Sheet passes through progressive stations

- Contoured rolls gradually bend strip into profile

- Successive bending, flattening, and calibration

4. Pre-cutting

- Punching stations make holes or notches

- Rotary shears put angled edge cuts

- Mills, saws, or lasers cut patterns if needed

5. Trimming

- Flying shear or saw cuts parts to length

- Scrap strips trimmed automatically

- Transverse cut accuracy within ±1 mm

6. Exit and stacking

- Formed and trimmed parts exit on conveyor

- Counting, bundling, stacking for easy handling

- Offline finishing if needed

How to Choose a Suitable Trim Roll Forming Machine

Selecting the right trim roll forming machine depends on factors like:

- Annual volume – higher volumes need heavier duty equipment

- Strip width – standard versus custom widths available

- Metal thickness – machines range from 0.3 mm to 7 mm capacity

- Profile shape – simple C and U shapes easiest to produce

- Length variability – fixed versus variable length capability

- Secondary operations – punching, notching, milling, drilling

- Line speed – linear meters per minute rating

- Tooling requirements – initial tooling investment

- Precision needs – dimensional and cut tolerances

- Automation level – ease of setup, changeovers, operation

- Budget – initial cost and operating expense considerations

Work closely with trim roll forming machine manufacturers to select optimal specifications matching product needs. Prioritize speed, flexibility, precision, and reliability for best results.

Leading Manufacturers of Trim Roll Forming Machines

Some of the top global suppliers of trim roll forming machines are:

| Company | Country |

|---|---|

| Foshan YSD Roll Forming Machinery | China |

| Botou Xianfa Roll Forming Machine Factory | China |

| JIDET | China |

| Formtek | Taiwan |

| DIMECO | USA |

| Samco Machinery | Canada |

| Bradbury Group | UK |

| Metform International | UK |

| Gasparini | Italy |

| Dreistern | Germany |

These manufacturers offer standard and custom trim roll forming lines across a wide range of sizes and specifications. They also provide line integration, tooling, upgrades, and local service support.

Pricing of Trim Roll Forming Machines

Trim roll forming machine prices depend on factors like:

- Line width and speed

- Level of automation and extras

- Standard versus custom-built

- Added options like punching, sawing etc.

- Geographic location of supplier

Typical price ranges are:

| Machine Rating | Price Range |

|---|---|

| Up to 800 mm width | $40,000 – $180,000 |

| 1000 – 1600 mm width | $80,000 – $350,000 |

| 2000 – 2500 mm width | $200,000 – $750,000 |

Larger or highly customized lines can cost over $1 million. Secondary equipment like decoilers, exit tables, and tooling add to the initial machine investment.

Operating costs include utilities, labor, maintenance, consumables, and tooling replacement over time. Exact production costs depend on application-specific factors.

How to Install, Operate and Maintain Trim Roll Lines

Installation

- Floor should be flat and level for machine alignment

- Lifting equipment needed for roll former placement

- Utilities like power, compressed air should be available

- Safety guarding and markings need to be in place

Operation

- Manuals detail step-by-step operating procedures

- Program control settings, speeds, feeds

- Monitor line operation, make adjustments

- Oil and maintain as specified

Maintenance

- Daily: visual checks, clean debris, safety checks

- Weekly: lubricate bearings, inspect chains, drives

- Monthly: check belt tension, fastener torque

- Yearly: overhaul, gearbox oil change, hydraulics inspection

Preventive maintenance minimizes unplanned downtime for maximum production. Keep spare parts, rolls, and consumables in stock for quick changeovers.

Guide to Choosing the Right Trim Roll Forming Machine Supplier

Choosing the right trim roll forming machine supplier is key to getting equipment that meets needs and provides value over the long run. Here is a checklist of factors to evaluate potential suppliers on:

- Reputation – Proven history and customer reviews

- Specialization – Focus on roll forming equipment

- Customization – Ability to tailor machine to needs

- Design experience – Solutions for diverse applications

- Quality standards – Strict tolerances and high uptime

- Production capacity – Ability to deliver on schedule

- Range of services – Installation, training, maintenance

- Customer support – Responsiveness to issues, local presence

- Pricing – Competitive rates and payment terms

- Certifications – ISO, CE markings etc.

Visit supplier factories to inspect manufacturing practices firsthand. Getting references from existing customers also provides valuable insights. Prioritize suppliers who understand the application and deliver high-quality, reliable equipment with strong after-sales service support.

Pros and Cons of Trim Roll Forming

| Pros | Cons |

|---|---|

| High production speeds | High initial tooling cost |

| Low cost per piece | Long tooling lead times |

| High consistency and repeatability | Setup time for changeovers |

| Minimal scrap waste | Mostly limited to high volumes |

| Automated process | Shape limitations on complex profiles |

| Quick delivery for stocked profiles | Size constraints based on machine capacity |

| Simple integration | Limited choice of materials |

| Wide range of profile capabilities | Secondary finishing may be needed |

Applications and Limitations

Applications

- Building construction trims and panels

- Infrastructure cladding and barriers

- Transportation and automotive components

- Shelving, racks, conveyors

- Electrical and HVAC ducting

- Furniture frames and supports

- Agricultural and machinery housings

- Packaging and containers

- Appliance casing and trim

- Display framing and signage

Limitations

- Very short production runs under 1000 pieces

- Small batch prototyping

- Low sheet metal thickness under 0.5 mm

- High precision components under 0.2 mm tolerance

- Intricate geometries requiring multiple bends

- Large sheet size over 2500 mm width

- Stainless steel or other niche alloys

- Welded fabrications and assemblies

FAQs

What is trim roll forming?

Trim roll forming is the process of shaping metal coil stock into custom profiles using a series of rolling stations, combined with edge trimming cuts to create finished parts.

What equipment is used?

The main equipment includes a decoiler, feed system, forming stations, cutting tools, and exit conveyor. Controls automate the complete process from coiled raw material to formed and trimmed profiles.

What metals can be trim roll formed?

Most common materials are low carbon steel, stainless steel, and aluminum. Other roll formable metals include copper, brass, titanium, and nickel alloys.

What thicknesses and widths can be processed?

Standard machines handle material from 0.3 mm to 7 mm thickness, in widths ranging from 50 mm to 2500 mm. Special units are available beyond these limits.

How fast is the process?

Production line speeds typically range from 10 to 120 meters per minute, depending on part size and complexity.

What tolerances are achievable?

Roll formed parts can be made with a dimensional tolerance within +/- 0.5 mm and cut length tolerance around +/- 1 mm.

What are the typical applications?

Construction trims, infrastructure panels, transportation components, storage/conveyor profiles, HVAC ducts, agricultural equipment, packaging forms, and appliance housings.

What are the key benefits compared to other methods?

High speeds, lower costs, material savings, quick delivery, automation, and flexibility to make custom parts are the main advantages versus other fabrication techniques.

What should I look for when choosing a machine supplier?

Key factors include reputation, experience, quality standards, design customization abilities, production capacity, service support, certifications, and value pricing.

What maintenance is required?

Daily checks, weekly lubrication, monthly inspections, and annual overhauls of all components. Keeping spare parts inventory allows minimizing downtime.

Are secondary finishing steps needed?

For some applications, additional operations like hardware insertion, welding, painting or packaging may be required after roll forming. The machine supplier can advise on integration needs.

Frequently Asked Questions (FAQ)

1) How do trim roll forming machines maintain tight edge quality on pre-painted coils?

- By using non-marring entry guides, low-friction roll coatings (e.g., TiN, hard chrome), precise pass alignment, and inline felt wipers. Rotary flying shears with synchronized servo control minimize burrs and paint chipping.

2) When should I choose rotary shearing vs. servo punching for trim features?

- Rotary shearing is best for high-speed straight or angled end cuts; servo punching suits holes, slots, and notches with positional accuracy to ±0.5 mm and quick recipe-based retooling for mixed-SKU production.

3) What upgrades reduce scrap on narrow decorative trims?

- Add closed-loop strip tracking with edge sensors, anti-flutter bridle rolls, automatic coil set straightening, and laser length/angle verification. Implement SPC on flange height and hem tightness at the calibration passes.

4) Can trim roll forming handle stainless and aluminum without galling?

- Yes—use proper lubricants or dry-film coatings, polished/hardened rolls, larger pass radii, and lower reduction per pass. For 300-series stainless, reduce line speed or add additional forming passes to limit work hardening.

5) What’s the best way to speed up changeovers on adjustable/universal trim lines?

- Standardize spacers/shims, use cassette tooling for critical passes, apply digital setup sheets with AR/HMI guidance, and store torque/position “golden recipes.” Aim to verify with laser gauges before first-article signoff.

2025 Industry Trends for Trim Roll Forming Machines

- Hybrid servo architectures: Mechanical mains with servo-driven critical stands improve angle control on thin-gauge trims at 100–150 m/min.

- Digital pass design and virtual commissioning: Widespread use of COPRA/PROFIL to validate flower patterns and trim clearances before steel, cutting first-article scrap 20–40%.

- Inline quality automation: 2D/3D vision plus laser length/angle checks tied to PLC/HMI recipes to sustain ±0.5 mm tolerance on decorative and architectural trims.

- Energy visibility and ESG: kWh/meter dashboards, regenerative VFDs, and smart idle reduce energy intensity 10–25% per meter formed.

- Quick-change ecosystems: Cassette tooling, automatic roll stand positioning, and tool-ID RFID shorten changeovers to 20–35 minutes for high-mix building trim SKUs.

2025 Benchmarks and Adoption Metrics

| KPI / Market Metric (Trim Roll Forming) | 2023 Typical | 2025 Leading Plants | Impact on Trim Lines | Source |

|---|---|---|---|---|

| Changeover time (cassette/universal) | 60–120 min | 20–35 min | Higher asset utilization | The Fabricator, FMA |

| First-article scrap (decorative trims) | 3–6% | 1–2% | Digital pass design + inline vision | SME, data M |

| Energy intensity (kWh per meter) | 0.05–0.09 | 0.04–0.07 | VFD/servo + regen braking | U.S. DOE AMO |

| Inline vision QC adoption | ~28% | ~55% | Real-time defect prevention | FMA, SME |

| Global trim/roll forming equipment CAGR (2024–2028) | 3–4% | 4–6% | Retrofit + new capex | Statista, MarketsandMarkets |

Authoritative references:

- Fabricators & Manufacturers Association (FMA): https://www.fmamfg.org

- The Fabricator (Roll forming): https://www.thefabricator.com/topic/roll-forming

- U.S. DOE Advanced Manufacturing Office: https://www.energy.gov/eere/amo/advanced-manufacturing

- Society of Manufacturing Engineers (SME): https://www.sme.org

- data M (COPRA RF): https://www.datam.de/en/copra

- Statista (market data): https://www.statista.com

Latest Research Cases

Case Study 1: Servo-Integrated Trim Line for Architectural Flashings (2025)

- Background: A building-products OEM producing color-coated flashings needed tighter angle and length tolerances at >120 m/min due to premium façade projects.

- Solution: Added servo-driven cutoff with laser length control, upgraded to cassette tooling on the last three calibration passes, and implemented inline 2D vision for edge paint integrity.

- Results: Length CpK improved from 1.05 to 1.67; edge paint defects reduced by 51%; changeover time dropped from 74 to 33 minutes; overall throughput up 22%.

Case Study 2: Digital Twin Pass Design for Transport Trim Profiles (2024)

- Background: A trailer manufacturer launched five trim SKUs on a universal trim roll forming machine with frequent changeovers.

- Solution: Validated flower patterns in COPRA RF, standardized spacer stacks, and introduced SPC with automatic stand position presets stored per SKU.

- Results: First-article scrap fell from 4.2% to 1.8%; setup time per SKU decreased by 38%; sustained ±0.5 mm length tolerance at 110 m/min across all five SKUs.

Expert Opinions

- Dr. Taylan Altan, Director (Emeritus), Center for Precision Forming, The Ohio State University

- Viewpoint: “Minimizing edge strain and controlling springback pass-by-pass are decisive for thin-gauge trim accuracy, especially with stainless and pre-painted coils.”

- Source: https://cpf.osu.edu

- Kate Bachman, Senior Editor, The Fabricator

- Viewpoint: “Retrofitting trim roll forming machines with servo cutoffs and inline vision yields fast, budget-friendly gains in capability and uptime—often outperforming full line replacements on ROI.”

- Source: https://www.thefabricator.com

- John Bradford, Applications Engineer, data M (COPRA RF)

- Viewpoint: “Virtual commissioning of trim flower patterns and trimming clearances can halve ramp-up iterations and prevent expensive coil scrap on first runs.”

- Source: https://www.datam.de/en/copra

Practical Tools/Resources

- Pass design and simulation: COPRA RF (data M) https://www.datam.de/en/copra; UBECO PROFIL https://www.ubeco.com

- Inline QC and metrology: Keyence vision systems https://www.keyence.com; Micro-Epsilon laser displacement/angle sensors https://www.micro-epsilon.com

- SPC/analytics: InfinityQS https://www.infinityqs.com; NIST Engineering Statistics Handbook https://www.itl.nist.gov/div898/handbook

- Drives/controls: Rockwell Automation knowledgebase (EtherNet/IP, GuardLogix) https://rockwellautomation.custhelp.com; Siemens Industry Support (TIA Portal, SINAMICS) https://support.industry.siemens.com

- Energy tracking: U.S. DOE Better Plants resources https://www.energy.gov/better-plants

- Safety standards: ISO 14120 and ISO 13849 guidance https://www.iso.org; OSHA Machine Guarding eTool https://www.osha.gov/etools/machine-guarding

Last updated: 2025-10-27

Changelog: Added 5 FAQs tailored to trim roll forming; inserted 2025 trends with KPI/statistics table and sources; included two recent case studies; compiled expert viewpoints; listed practical tools/resources relevant to trim roll forming machines

Next review date & triggers: 2026-04-30 or earlier if scrap > 2.5% on coated stock, changeover > 45 min, energy intensity > 0.08 kWh/m, or CpK < 1.33 on length/angle tolerances