Choosing the right corrugated sheet roll forming machine is critical for the success of any manufacturing business. The performance of the machine can directly impact the quality of the finished product, as well as the efficiency and profitability of the business. Corrugated sheets are used in a variety of industries, including construction, automotive, and packaging, among others. Therefore, selecting the right machine is essential to meet the unique requirements of each application. In this post, we will discuss expert tips for choosing the right corrugated sheet roll forming machine. By considering various factors such as material type, production volume, required precision, available space, businesses can make informed decisions and achieve optimal results.

material type of a corrugated sheet roll forming machine

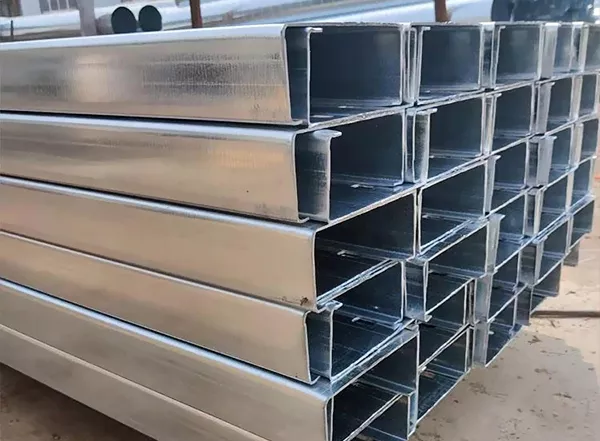

The material type is a critical factor to consider when selecting a corrugated sheet roll forming machine. Different materials can have varying specifications and configurations, which can significantly impact the machine’s performance. For example, the thickness and strength of the material can affect the required tonnage of the roll forming machine, the number of forming stands, and the configuration of the tooling.

Moreover, different materials require different types of tooling and machinery setups. For instance, steel requires more robust and durable tooling, while aluminum requires more delicate tooling due to its softness. Similarly, some materials may require specialized lubrication or cooling systems to ensure the proper operation of the roll forming machine.

Considering the material type is essential to ensure that the roll forming machine is capable of processing the desired material effectively and efficiently. Failure to consider the material type may result in inadequate performance, increased downtime, and ultimately, lower quality finished products.

Therefore, it is crucial to consult with an experienced roll forming machine supplier or manufacturer to determine the appropriate machine specifications and configurations for the desired material type. This can help ensure that the machine can effectively process the material and achieve the desired production output, quality, and efficiency.

Production Volume of corrugated sheet roll forming machine

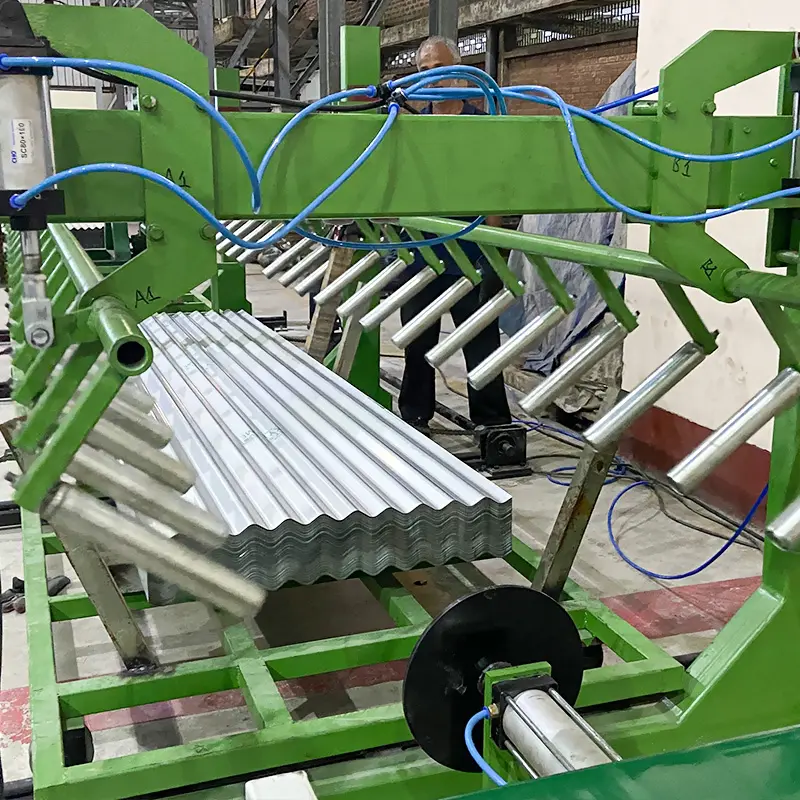

Production volume is another important factor to consider when selecting a corrugated sheet roll forming machine. Different types of machines are available, each with varying production speeds and capacities. Choosing the right machine can significantly impact the efficiency and profitability of a manufacturing business.

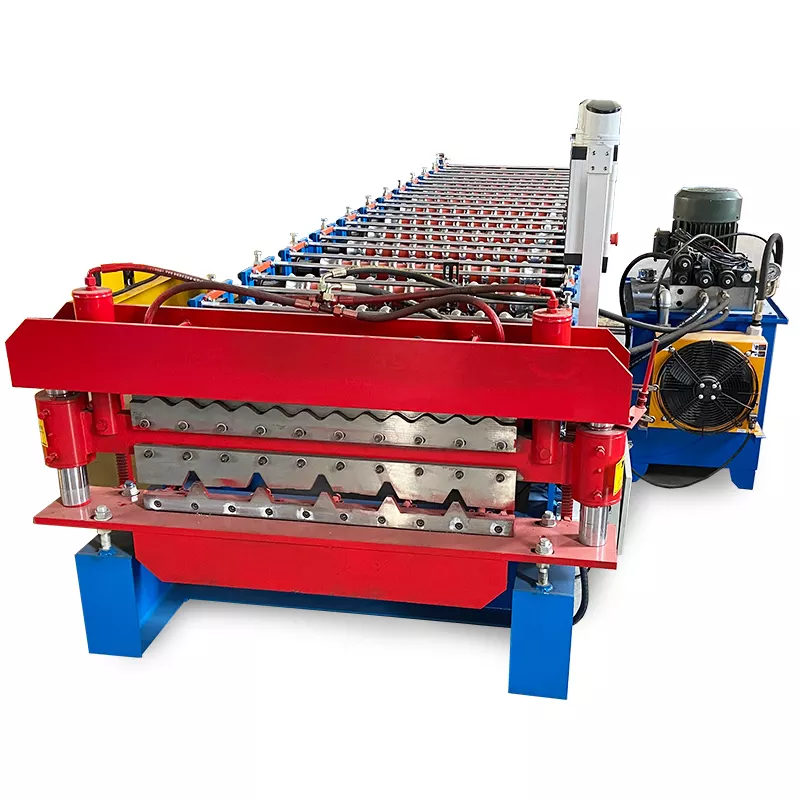

For instance, if a business requires a high production volume, a double-head roll forming machine may be more suitable than a single-head machine. Double-head machines can process two sheets simultaneously, effectively doubling the production output. They can also reduce labor costs by requiring fewer operators.

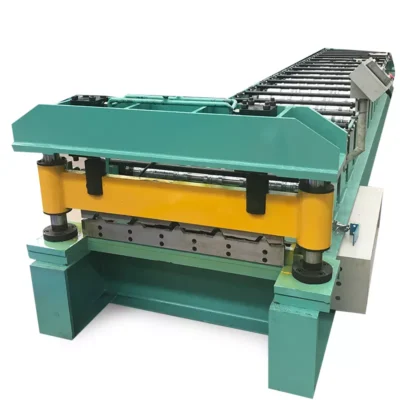

On the other hand, a single-head machine may be more suitable for lower production volumes. These machines are often less expensive and require less floor space than double-head machines. Single-head machines are also generally easier to maintain and repair than double-head machines.

In addition to single-head and double-head machines, other types of corrugated sheet roll forming machines are available, including machines with integrated cutting and punching capabilities. These machines can increase production efficiency by eliminating the need for separate cutting and punching operations.

It is essential to choose a machine that can handle the desired production volume and output without sacrificing quality or efficiency. Working with an experienced roll forming machine supplier or manufacturer can help determine the appropriate machine type and configuration for the specific production needs of the business.

In summary, production volume is a crucial factor to consider when selecting a corrugated sheet roll forming machine. Different types of machines are available, each with varying production speeds and capacities, such as single-head or double-head machines. Choosing the right machine can significantly impact the efficiency and profitability of a manufacturing business, and consulting with an expert can help ensure that the chosen machine meets the business’s specific production needs.

required precision of corrugated sheet roll forming machine

The required precision is another crucial factor to consider when selecting a corrugated sheet roll forming machine. Different machines may have varying levels of precision and accuracy, which can significantly impact the quality of the finished product.

For instance, if the finished product requires tight tolerances and precise dimensions, a machine with higher precision and accuracy may be necessary. These machines may have more robust control systems, advanced sensors, and tighter manufacturing tolerances to ensure consistent performance and dimensional accuracy.

In contrast, a machine with lower precision and accuracy may be suitable for applications that require less precision, such as roofing or siding. However, using a machine with lower precision than necessary can result in dimensional inaccuracies, which can impact the quality of the finished product and increase scrap rates.

Therefore, it is essential to consider the required precision when selecting a corrugated sheet roll forming machine. Choosing the right machine can ensure that the finished product meets the desired dimensional tolerances and specifications, ultimately improving the quality and consistency of the final product.

Additionally, it is crucial to properly maintain and calibrate the machine to ensure that it remains accurate and precise over time. Regular inspections, maintenance, and calibration can prevent wear and tear and ensure that the machine is performing at its best.

In summary, the required precision is a crucial factor to consider when selecting a corrugated sheet roll forming machine. Different machines may have varying levels of precision and accuracy, which can impact the quality of the finished product. Choosing the right machine and maintaining it properly can ensure that the final product meets the desired dimensional tolerances and specifications, improving quality and consistency.

Available Space of corrugated sheet roll forming machine

The available space is another important factor to consider when selecting a corrugated sheet roll forming machine. Different machines have varying footprints and space requirements, which can significantly impact the layout and design of a manufacturing facility.

For instance, a larger machine with a larger footprint may require more floor space and headroom than a smaller machine. Additionally, some machines may require specific layout configurations, such as being installed against a wall or requiring overhead crane access for maintenance.

It is crucial to ensure that the machine’s size and space requirements are compatible with the available manufacturing facility space. Choosing a machine that is too large for the space can result in inefficient use of the available space, while selecting a machine that is too small can limit production capacity and output.

Furthermore, the machine’s location within the manufacturing facility can also impact workflow efficiency and safety. The machine should be located in an area that allows for easy material handling, efficient material flow, and safe access for operators.

Considering the available space when selecting a corrugated sheet roll forming machine can help ensure that the machine fits within the available manufacturing facility space and is positioned for optimal workflow efficiency and safety.

In summary, available space is an important factor to consider when selecting a corrugated sheet roll forming machine. Different machines have varying footprints and space requirements, which can significantly impact the layout and design of a manufacturing facility. Choosing a machine that is compatible with the available space and optimally positioned for workflow efficiency and safety can improve manufacturing productivity and reduce the risk of accidents or injuries.

Choosing the right corrugated sheet roll forming machine is crucial to achieving the desired production output, quality, and efficiency. By considering various factors such as material type, production volume, required precision, available space, automation, and quality control, businesses can make informed decisions and select a machine that meets their specific needs. Working with an experienced roll forming machine supplier or manufacturer can provide valuable guidance and ensure that the chosen machine is compatible with the manufacturing facility and production requirements. By following expert tips, businesses can maximize the benefits of their corrugated sheet roll forming machine and achieve optimal results.