C channel roll forming machines are essential pieces of equipment for any manufacturing process that involves shaping metal or other materials into specific shapes. Their versatility makes them popular among manufacturers in a wide range of industries. In this guide, we’ll explore the many different applications of C channel roll forming machines in manufacturing, as well as their advantages and customization options. Whether you’re a seasoned manufacturer or just getting started, this guide will provide you with the knowledge you need to understand the versatility of C channel roll forming machines and how they can benefit your production processes.

Introduction to C Channel Roll Forming Machines

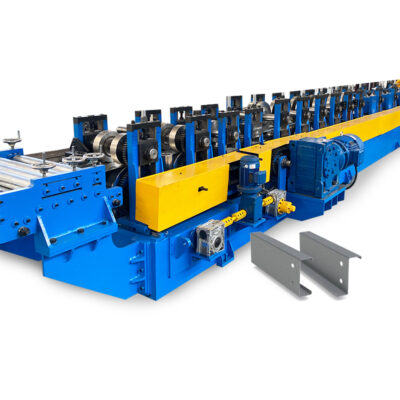

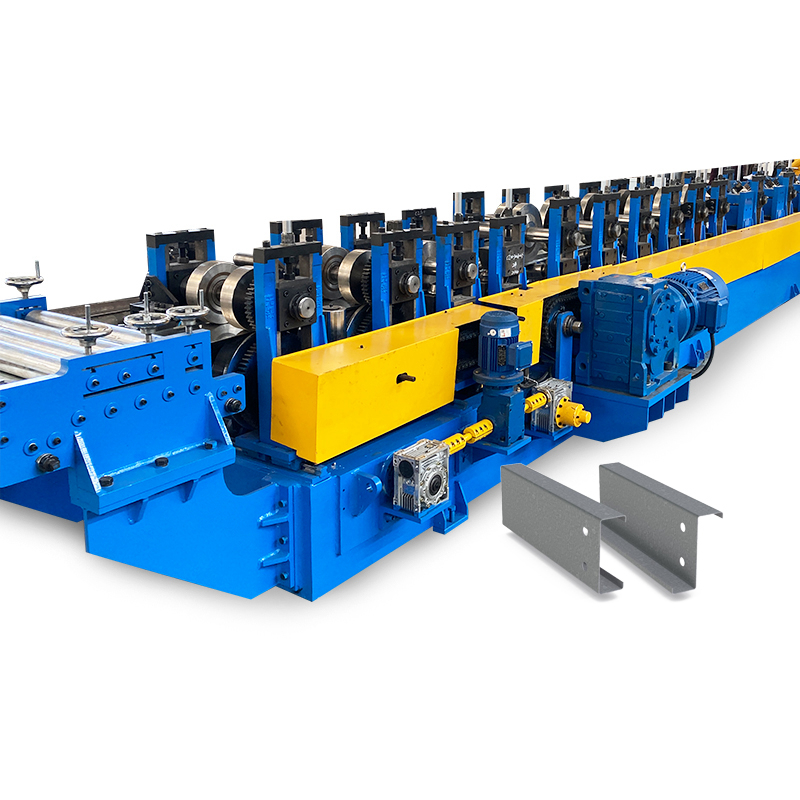

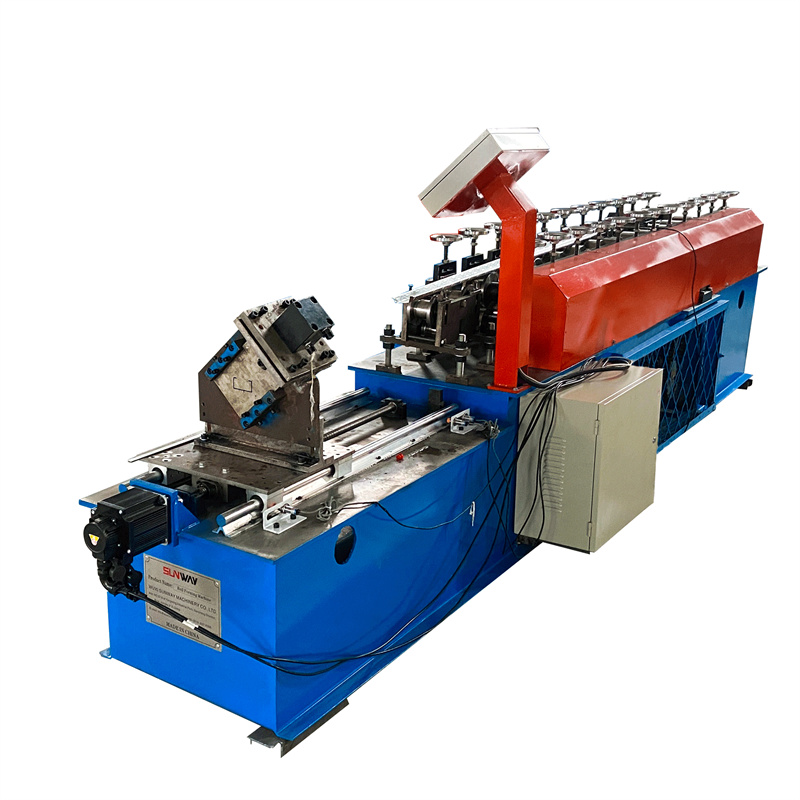

C channel roll forming machines are specialized pieces of equipment used in the manufacturing industry to shape metal or other materials into C-shaped profiles. These machines work by feeding a strip of material through a series of rollers that gradually bend it into the desired shape. The process is precise and highly efficient, making it a popular choice for manufacturers who require high-quality products at high production volumes.

One of the key features of C channel roll forming machines is their versatility. They can be used to produce a wide range of products, from structural elements in buildings to support beams for industrial equipment, and frames for conveyor systems. Additionally, they can handle a variety of materials, including steel, aluminum, and other metals, as well as plastics and composite materials.

Another advantage of C channel roll forming machines is their high level of precision. The rollers on the machine can be adjusted to produce profiles with exact measurements, ensuring that each product is uniform and meets the required specifications. This level of precision is particularly important in industries like construction and aerospace, where safety and quality standards are paramount.

In summary, C channel roll forming machines are versatile, precise, and efficient pieces of equipment used in a wide range of manufacturing applications. Their ability to produce high-quality products at high production volumes makes them a popular choice among manufacturers looking to optimize their production processes.

Advantages of C Channel Roll Forming Machines

C channel roll forming machines offer several advantages for manufacturers looking to optimize their production processes. Here are some of the benefits of using C channel roll forming machines:

- High Efficiency: C channel roll forming machines are highly efficient, allowing manufacturers to produce high volumes of products quickly and at a lower cost compared to other manufacturing processes. They can produce large batches of products in a single pass, reducing the number of steps required in the production process.

- Precision: C channel roll forming machines are capable of producing products with exact measurements, ensuring that each product is uniform and meets the required specifications. This precision is particularly important in industries where safety and quality standards are paramount.

- Versatility: C channel roll forming machines can handle a wide range of materials, including metals, plastics, and composite materials, making them a versatile choice for manufacturers in a variety of industries.

- Customization: C channel roll forming machines can be customized to produce specific profiles or shapes, making them ideal for manufacturers who require specialized products or unique designs.

- Cost-Effective: C channel roll forming machines are a cost-effective manufacturing solution, especially for high-volume production. They can produce products quickly and efficiently, reducing labor costs and minimizing waste.

In summary, C channel roll forming machines offer several advantages for manufacturers, including high efficiency, precision, versatility, customization, and cost-effectiveness. These benefits make them a popular choice for manufacturers looking to optimize their production processes and improve their bottom line.

Applications of C Channel Roll Forming Machines

C channel roll forming machines have a wide range of applications in the manufacturing industry. Here are some of the most common applications of C channel roll forming machines:

- Building Construction: the machines are commonly used to produce structural elements for buildings, such as door frames, window frames, and roof trusses. The ability to produce C-shaped profiles with precise measurements makes them ideal for these applications.

- Industrial Equipment: the machines are also used to produce support beams for industrial equipment, such as conveyors, cranes, and heavy machinery. These support beams require high precision and durability to withstand the weight and pressure of the equipment they support.

- Automotive Industry: the machines are used to produce parts for the automotive industry, including chassis components, seat frames, and door panels. These parts require high precision and consistency to ensure the safety and performance of the vehicle.

- HVAC Systems: the machines can produce air ducts and HVAC components, including furnace ducts, air conditioner frames, and ventilation systems.

- Solar Panel Frames: the machines are also used to produce frames for solar panels. The precise measurements and durability of C channel profiles make them an ideal choice for supporting solar panels.

In summary, C channel roll forming machines have a wide range of applications in the manufacturing industry, including building construction, industrial equipment, automotive industry, HVAC systems, and solar panel frames. The ability to produce high-precision C-shaped profiles makes them a versatile choice for a variety of applications.

Successfully Implemented examples of C channel roll forming machines

Here are a few examples of companies that have successfully implemented C channel roll forming machines in their manufacturing processes:

- Johnson Controls: Johnson Controls, a leading manufacturer of automotive batteries and HVAC equipment, implemented the machines to produce frame components for their HVAC systems. The machines allowed them to produce high-precision frames with consistent measurements, improving the quality of their products and reducing waste.

- Atlas Steel Products: Atlas Steel Products, a metal processing company, implemented the machines to produce support beams for industrial equipment. The machines allowed them to produce support beams with precise measurements and high strength, reducing the risk of equipment failure and increasing safety in their production processes.

- Inductotherm Heating & Welding Ltd.: Inductotherm Heating & Welding Ltd., a manufacturer of industrial furnaces, implemented the machines to produce the support frames for their furnaces. The machines allowed them to produce frames with high precision and consistency, improving the quality of their products and reducing production time.

- NCI Building Systems: NCI Building Systems, a leading manufacturer of building materials, implemented the machines to produce framing components for their buildings. The machines allowed them to produce high-quality frames with consistent measurements, improving the efficiency of their production processes and reducing waste.

In summary, these companies have successfully implemented C channel roll forming machines in their manufacturing processes, improving the quality and efficiency of their production processes. They have experienced benefits such as high precision, consistency, strength, and cost-effectiveness, making C channel roll forming machines a popular choice for manufacturers looking to optimize their production processes.

In conclusion, C channel roll forming machines are versatile, precise, and efficient pieces of equipment used in a wide range of manufacturing applications. They offer several advantages, including high efficiency, precision, versatility, customization, and cost-effectiveness. These benefits make them a popular choice for manufacturers looking to optimize their production processes and improve their bottom line. With the ability to produce high-quality products at high production volumes, C channel roll forming machines offer an excellent solution for manufacturers across a range of industries.