The construction industry has always been at the forefront of innovation, constantly searching for new and more efficient ways to build structures. One such innovation that has made a significant impact on the industry is the shutter door roll forming machine. These machines have revolutionized the way doors are created and installed, providing numerous benefits over traditional door fabrication methods. In this post, we will explore the impact of shutter door roll forming machines on the construction industry and discuss their advantages, applications, and future trends. So let’s dive in and take a closer look at this game-changing technology.

Advantages of Shutter Door Roll Forming Machines

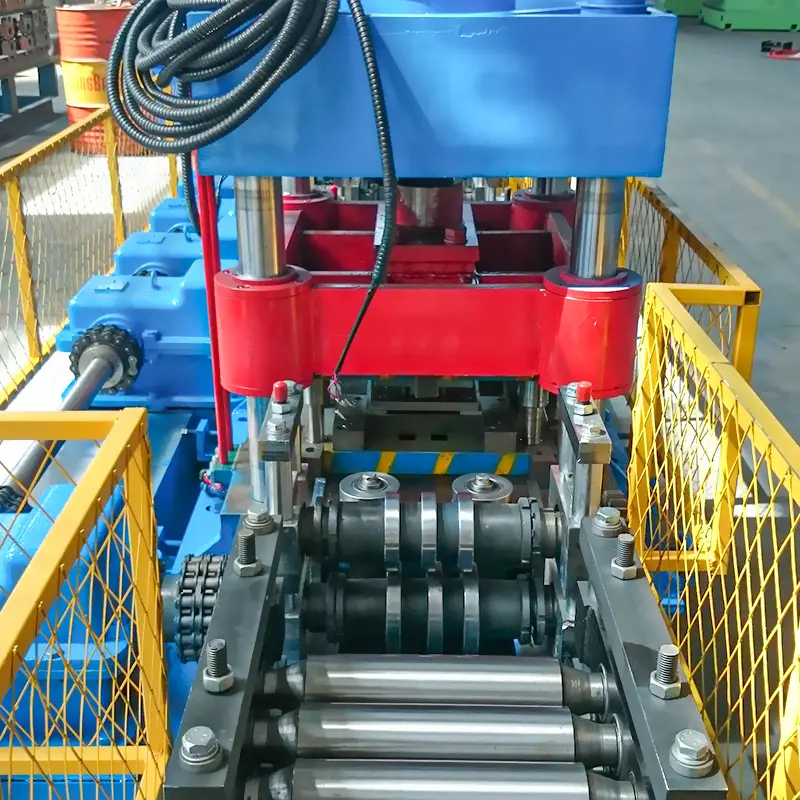

Shutter door roll forming machines offer several advantages over traditional door fabrication methods. Here are some of the key benefits:

- Precision: Shutter door roll forming machines use computer-controlled systems to create doors with a high level of precision. This ensures that the doors fit perfectly into the openings they are designed for, reducing the risk of air leaks and other problems.

- Efficiency: These machines can create doors quickly and efficiently, reducing the time required for door fabrication. This can help to speed up construction projects and save contractors time and money.

- Speed: Shutter door roll forming machines can create doors at a much faster rate than traditional door fabrication methods. This means that contractors can get the doors they need when they need them, reducing project delays and increasing overall productivity.

- Cost-effectiveness: Because shutter door roll forming machines can create doors quickly and efficiently, they are often more cost-effective than traditional door fabrication methods. This can help contractors save money on labor and material costs, making it easier to stay within budget.

In addition to these advantages, shutter door roll forming machines can also create doors in a wide range of sizes, shapes, and materials. This makes them highly versatile and well-suited to a variety of construction projects. Overall, the precision, efficiency, speed, and cost-effectiveness of these machines make them an excellent choice for contractors looking to streamline their door fabrication process and improve their bottom line.

Applications of Shutter Door Roll Forming Machines

-

Vineyard Post Roll Forming Machine

Vineyard Post Roll Forming Machine -

Auto Size Changeable Sigma Purlin Roll Forming Machine

Auto Size Changeable Sigma Purlin Roll Forming Machine -

PV Mounting Bracket C Shape Profile Roll Forming Machine

PV Mounting Bracket C Shape Profile Roll Forming Machine -

C Z Purlin Channel Cold Roll Forming Machine Full Auto Galvanized Steel Profile

C Z Purlin Channel Cold Roll Forming Machine Full Auto Galvanized Steel Profile -

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile)

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile) -

PV Mounting Bracket Z Shape Profile Roll Forming Machine

PV Mounting Bracket Z Shape Profile Roll Forming Machine

Shutter door roll forming machines have numerous applications in the construction industry. Here are some of the most common uses for these machines:

- Industrial Buildings: Shutter door roll forming machines are widely used to create doors for industrial buildings, including factories, warehouses, and manufacturing facilities. These doors are typically made from steel or aluminum and can be customized to fit a wide range of openings.

- Commercial Buildings: Shutter door roll forming machines can also be used to create doors for commercial buildings, such as retail stores, offices, and hotels. These doors can be made from a variety of materials, including wood, aluminum, and glass, and can be customized to fit specific design requirements.

- Residential Buildings: Shutter door roll forming machines can create doors for residential buildings as well, including garage doors and security doors. These doors can be made from a variety of materials, including steel, aluminum, and fiberglass, and can be customized to fit a range of architectural styles.

- Agricultural Buildings: Shutter door roll forming machines can create doors for agricultural buildings, such as barns and sheds. These doors are typically made from steel or aluminum and can be designed to provide ventilation and natural light.

- Transportation: Shutter door roll forming machines can also be used to create doors for transportation infrastructure, such as airport hangars and bus depots. These doors can be made from steel or aluminum and can be customized to fit the specific needs of the transportation industry.

Overall, the versatility of shutter door roll forming machines makes them well-suited to a wide range of construction applications. They can be customized to fit a variety of materials, sizes, and shapes, and can be used to create doors for virtually any type of building.

The Use Of Shutter Door Roll Forming Machines Impact on Construction Industry

The use of shutter door roll forming machines has had a significant impact on the construction industry. Here are some of the key ways that these machines have changed the way construction projects are executed:

- Increased Productivity: Shutter door roll forming machines can create doors quickly and efficiently, reducing the time required for door fabrication. This has helped to speed up construction projects, allowing contractors to complete jobs faster and move on to the next project more quickly.

- Reduced Labor Costs: Because shutter door roll forming machines can create doors quickly and efficiently, they require less labor than traditional door fabrication methods. This can help to reduce labor costs, making it easier for contractors to stay within budget.

- Improved Quality Control: Shutter door roll forming machines use computer-controlled systems to create doors with a high level of precision. This ensures that the doors fit perfectly into the openings they are designed for, reducing the risk of air leaks and other problems. This has helped to improve the overall quality of construction projects.

- Enhanced Customization: Shutter door roll forming machines can be customized to fit a wide range of materials, sizes, and shapes. This has allowed contractors to create doors that are tailored to the specific needs of their projects, improving overall project efficiency.

- Streamlined Supply Chain: By using shutter door roll forming machines, contractors can reduce their reliance on third-party door manufacturers. This can help to streamline the supply chain and reduce the risk of delays or issues with door delivery.

Overall, the use of shutter door roll forming machines has helped to increase productivity, reduce labor costs, and improve quality control in the construction industry. By providing contractors with a more efficient and customizable way to create doors, these machines have helped to streamline construction projects and improve the bottom line for contractors.

Future Trends of shutter door roll forming machine

As with any technology, shutter door roll forming machines are constantly evolving and improving. Here are some emerging trends in shutter door roll forming machine technology and how they may impact the construction industry in the future:

- Automation: Shutter door roll forming machines are becoming increasingly automated, allowing for more efficient and precise door fabrication. This trend is likely to continue, with more advanced automation technologies being developed to improve the speed and accuracy of door creation.

- Integration with CAD/CAM Software: Many shutter door roll forming machines now integrate with computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This integration allows contractors to create and modify door designs digitally, making it easier to customize doors for specific projects.

- Use of Advanced Materials: As new materials become available, shutter door roll forming machines are likely to be adapted to accommodate them. For example, machines that can create doors from advanced composite materials are already being developed, which could open up new possibilities for door design and construction.

- Portable and Modular Machines: Some manufacturers are developing portable and modular shutter door roll forming machines that can be easily transported and set up on construction sites. These machines could allow contractors to create doors on-site, reducing the need for transportation and storage of pre-fabricated doors.

- Sustainable Manufacturing: As sustainability becomes a more pressing concern in the construction industry, shutter door roll forming machines are likely to be adapted to accommodate sustainable materials and manufacturing processes. For example, machines that can create doors from recycled materials or with minimal waste may become more common in the future.

Overall, the future of shutter door roll forming machine technology looks promising. As the construction industry continues to evolve, these machines are likely to play an increasingly important role in the creation of high-quality, efficient doors for a wide range of applications.

Shutter door roll forming machines have revolutionized the way doors are fabricated and installed in the construction industry. The precision, efficiency, speed, and cost-effectiveness of these machines have had a significant impact on the industry, increasing productivity, reducing labor costs, and improving quality control. As these machines continue to evolve and improve, they are likely to become an increasingly important tool for contractors looking to streamline their construction projects.