Shutter door roll forming machines are an essential tool in the construction industry, particularly in the manufacturing of shutters for doors and windows. These machines use a series of rollers to bend and shape metal sheets into the desired form, resulting in precise and uniform products. The evolution of these machines has played a crucial role in the development of the construction industry, making it faster, more efficient, and more cost-effective. In this post, we will explore the evolution of shutter door roll forming machines, from their early designs to the modern, computerized models used today. We will also discuss their applications and potential future developments.

Early designs of shutter door roll forming machines

The earliest designs of shutter door roll forming machines date back to the 19th century when manual machines were used to form metals manually. These early machines were operated by hand and relied on the skill and experience of the operator to produce the desired results.

The early machines were made of heavy-duty cast iron frames and had sets of rollers that were manually adjusted to create the required shape of the metal. The metal sheets were fed into the machine and then guided through the rollers by the operator. The rollers used in these machines were made of steel or cast iron and were adjusted by screws to change the spacing between them, allowing for the formation of different shapes.

These early machines were designed to handle a range of metals, including copper, brass, and iron. They were mainly used in the production of shutters for doors and windows, as well as for other metal products.

As technology advanced, the design of the machines began to change. The manual machines were replaced by motorized machines that used electric motors to power the rollers. This made the process faster and more efficient, and allowed for greater precision in the forming of metal sheets.

Despite these improvements, early designs of shutter door roll forming machines remained relatively simple and straightforward, relying on basic mechanical principles to shape the metal sheets. However, this laid the groundwork for the development of more sophisticated machines in the years to come.

Advancements in technology

Over the years, advancements in technology have transformed the design and functionality of shutter door roll forming machines. One of the most significant developments has been the integration of automation and computerized controls, which has greatly improved the efficiency and accuracy of the machines.

With the introduction of computer numerical control (CNC) technology, operators can now program the machines to produce a wide range of shapes and sizes with greater accuracy and consistency. CNC machines use a computer program to guide the rollers, ensuring that the metal sheets are formed precisely according to the desired specifications.

In addition, many modern shutter door roll forming machines are equipped with automated features that simplify the production process and reduce the need for manual intervention. For example, some machines can automatically adjust the rollers to accommodate different thicknesses of metal sheets, reducing the time and effort required to change the settings manually.

Advancements in technology have also led to improvements in the materials used in shutter door roll forming machines. Modern machines are often made of lightweight, durable materials such as aluminum, which reduces their weight and makes them easier to transport and operate.

Overall, the integration of technology has transformed the design and functionality of shutter door roll forming machines, making them more efficient, accurate, and versatile than ever before. These machines now play a vital role in the construction industry, helping to produce high-quality shutters for doors and windows at a faster and more cost-effective rate.

Modern designs of shutter door roll forming machines

-

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Cable Ladder Roll Forming Machine

Cable Ladder Roll Forming Machine -

PV Mounting Bracket C Shape Profile Roll Forming Machine

PV Mounting Bracket C Shape Profile Roll Forming Machine -

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine -

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile)

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile) -

PV Mounting Bracket Z Shape Profile Roll Forming Machine

PV Mounting Bracket Z Shape Profile Roll Forming Machine -

Solar mounting strut channel roll forming machine

Solar mounting strut channel roll forming machine -

Strut Channel Roll Forming Machine

Strut Channel Roll Forming Machine

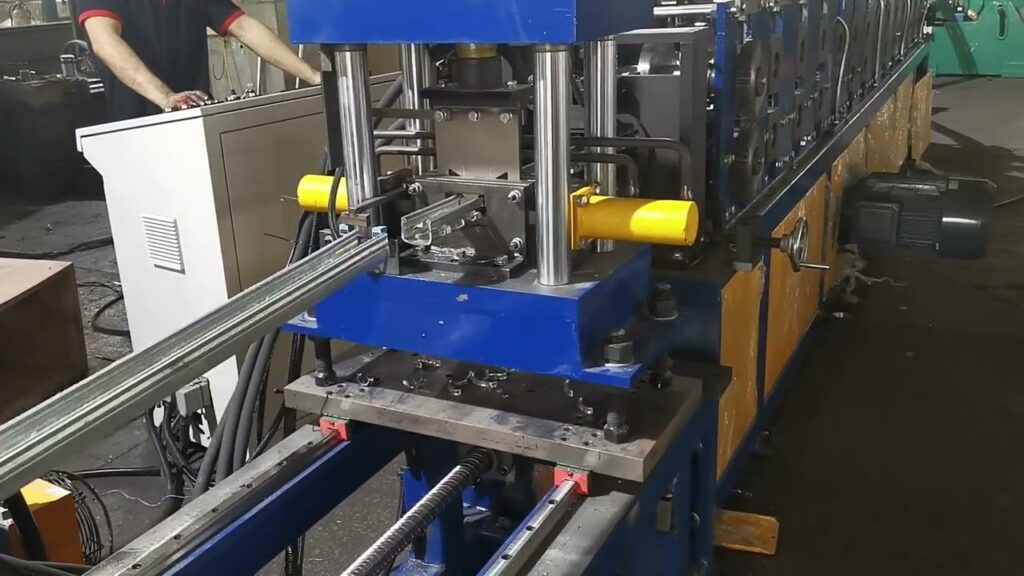

Modern shutter door roll forming machines have come a long way from their early designs. They are now available in a wide variety of designs and configurations, with many advanced features that make them more versatile and efficient.

One example of a modern shutter door roll forming machine is the adjustable roll forming machine. This machine is equipped with adjustable rollers that can be modified to create different shapes and sizes of shutters, making it a highly versatile tool. Additionally, modern machines are equipped with automated features, such as the ability to automatically adjust the rollers to accommodate different thicknesses of metal sheets. This eliminates the need for manual adjustments and helps to improve the accuracy and speed of production.

Another key feature of modern shutter door roll forming machines is their ability to work with a variety of materials. While early designs were limited to metals such as iron and copper, modern machines are capable of working with a range of materials, including aluminum, steel, and even plastic. This allows manufacturers to produce a wider range of products and cater to different customer needs.

Moreover, some modern machines are equipped with computer numerical control (CNC) technology, which allows for the production of highly complex shapes and designs. This technology enables manufacturers to create unique and intricate shutters for doors and windows that would be impossible to produce with earlier designs.

In terms of construction, modern shutter door roll forming machines are also designed with durability and ease of use in mind. They are often constructed using lightweight, durable materials, such as aluminum, which makes them easy to move and transport. Additionally, many modern machines are designed with user-friendly interfaces that allow operators to program and adjust the machines quickly and easily.

Overall, modern shutter door roll forming machines are highly versatile and efficient tools that offer a range of features and capabilities that were not available in earlier designs. With their ability to work with different materials and create complex shapes and designs, these machines have revolutionized the production of shutters for doors and windows.

Future developments of shutter door roll forming machines

As with all forms of technology, the future of shutter door roll forming machines is likely to be characterized by further advances in efficiency, precision, and versatility. Here are some potential developments that we may see in the coming years:

- Enhanced automation: One area in which we may see significant advancements is in the automation of the production process. This could include the introduction of more sophisticated sensors and controls that allow the machines to automatically adjust the rollers and other settings in response to changes in the metal sheets.

- Increased flexibility: We may also see shutter door roll forming machines that are even more versatile and adaptable than current models. This could involve the use of interchangeable tooling, allowing the machines to switch between different types of shutters or other products more quickly and easily.

- Improved material handling: Another area for potential improvement is in the way that the machines handle the metal sheets. New technologies may be developed that allow for more efficient loading and unloading of the sheets, reducing the need for manual intervention.

- Integration with other technologies: Finally, we may see the integration of shutter door roll forming machines with other technologies, such as artificial intelligence and machine learning. This could allow the machines to optimize their performance based on real-time data and improve their accuracy and efficiency even further.

Overall, the future of shutter door roll forming machines is likely to be marked by continued advancements in automation, flexibility, and precision. As these machines become more advanced and sophisticated, they will continue to play a vital role in the construction industry, helping to produce high-quality shutters for doors and windows at a faster and more cost-effective rate.

In summary, the article describes the evolution of shutter door roll forming machines over the years, starting from manually operated machines to the advanced automated machines available today. The article highlights the various improvements and innovations that have made these machines more efficient and cost-effective. With the continued advancements in technology and manufacturing processes, it is expected that shutter door roll forming machines will continue to evolve and become even more sophisticated, providing businesses with greater production capabilities and cost savings.