Drawer slides are a part of furniture that holds the moving parts of a drawer in place and prevent it from shifting or sliding. The drawer slides roll forming machine is an industrial-sized machinery that provides a highly efficient, cost-effective, and economical solution for producing high volumes of these components. The Drawer slide Roll Forming Machine is also a machine that provides benefits such as more speed and versatility, which allows for more efficiency in production. This article discusses the pros and cons of the drawer slides roll forming machine.

What is a Drawer Slides Roll Forming Machine?

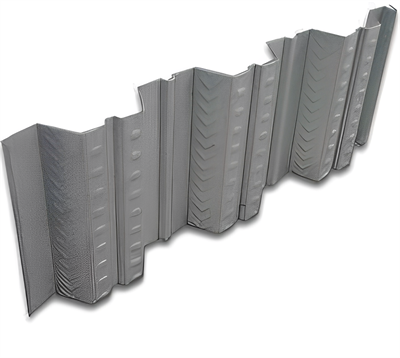

A drawer slide roll forming machine is a type of machinery used to create metal parts for drawers. The raw material, typically sheet metal, is fed into the machine where it is formed into the desired shape.

Drawer slide roll forming machines are used in a variety of industries, including furniture manufacturing, automotive manufacturing, and appliance manufacturing. These machines offer a high degree of accuracy and repeatability, which makes them ideal for producing large quantities of parts.

Drawer slides roll forming machines can produce parts with complex geometries, such as those found in furniture drawer slides. These machines can also be equipped with various accessories, such as punching and shearing devices, to create custom parts.

How to Use The Drawer Slides Roll Forming Machine?

If you are looking for an efficient and cost-effective way to produce drawer slides, then you should consider investing in a drawer slides roll forming machine. This type of machine can help you produce high-quality drawer slides quickly and easily, and it can also help you save money on production costs.

To use a drawer slides roll forming machine, first you will need to purchase the appropriate drawer slideforms. These can be found at most hardware stores or online. Once you have the forms, simply follow the instructions that come with the machine to load them into the proper position.

Once the forms are loaded, you will need to select the desired thickness for your drawer slides. The thicker the slide, the more expensive it will be to produce. However, thicker slides will also be more durable and last longer.

Once you have selected the thickness of your drawer slides, simply start the roll forming process. The machine will do all of the work for you, so all you need to do is sit back and watch as it produces high-quality drawer slides.

-

Carriage Board Roll Forming Machine

Carriage Board Roll Forming Machine -

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Two waves highway guardrail machine

Two waves highway guardrail machine -

Three waves highway guardrail machine

Three waves highway guardrail machine

Advantages of the Drawer Slides Roll Forming Machine

There are many advantages to using the drawer slides roll forming machine. One of the biggest advantages is that it can help you save time and money on your production costs. The machine is also very versatile, which means that you can use it to produce a variety of different products. Additionally, the drawer slides roll forming machine is very easy to operate, which makes it a great choice for those who are new to the manufacturing process.

Disadvantages of the Drawer Slides Roll Forming Machine

There are a few disadvantages to the drawer slides roll forming machine that should be considered before making a purchase. One of the biggest disadvantages is the cost. The machine itself is not cheap and then there are the costs associated with setting it up and maintaining it. Another disadvantage is that it can be difficult to change the settings on the machine if you need to produce a different size or type of drawer slide. Finally, some people find the noise produced by the machine to be bothersome.

How to Choose The Right Type of Drawer Slides Roll Forming Machine?

There are different types of drawer slides roll forming machines available in the market. So, how do you choose the right one for your needs? Here are some factors to consider:

- The type of material you will be using the machine for: Some machines are designed for specific materials, so it’s important to choose one that is compatible with the material you’ll be using. For example, if you’re looking for a machine to use with aluminum, make sure to choose an aluminum-compatible machine.

- The thickness of the material: This is an important factor to consider because it will affect the performance of the machine. If you’re working with thin material, make sure to choose a machine that can handle thin material.

- The size of the project: The size of your project will dictate the size of the machine you need. If you’re working on a large project, make sure to choose a machine that is designed for large projects.

- Your budget: Obviously, your budget is going to be a major factor in choosing the right machine. Make sure to set a budget and stick to it when choosing a machine.

- Your level of experience: If you’re new to using roll forming machines, make sure to choose a machine that is easy to use and understand. There are many different machines on the market, so don’t be afraid to ask for help from a salesperson or fellow user when making your decision.

Conclusion

The drawer slides roll forming machine has many benefits that make it an attractive option for businesses. It is a fast, efficient way to produce drawer slides, and it produces a consistent product. In addition, the machine is relatively easy to operate and maintain, and it is very versatile. With so many benefits, it’s no wonder that the drawer slides roll forming machine is becoming increasingly popular in a variety of industries.