Shutter doors are a popular choice for a wide range of applications, from industrial warehouses to commercial buildings. However, the traditional manufacturing methods for shutter doors can be time-consuming and labor-intensive, leading to high costs and longer project timelines. In recent years, the advent of shutter door roll forming machines has changed the game for the industry, providing a faster, more efficient way to produce high-quality shutter doors. In this post, we will compare shutter door roll forming machines with traditional manufacturing methods, exploring the advantages and disadvantages of each approach. So let’s dive into the world of shutter door manufacturing and see which method is better for your next project.

Shutter Door Roll Forming Machines

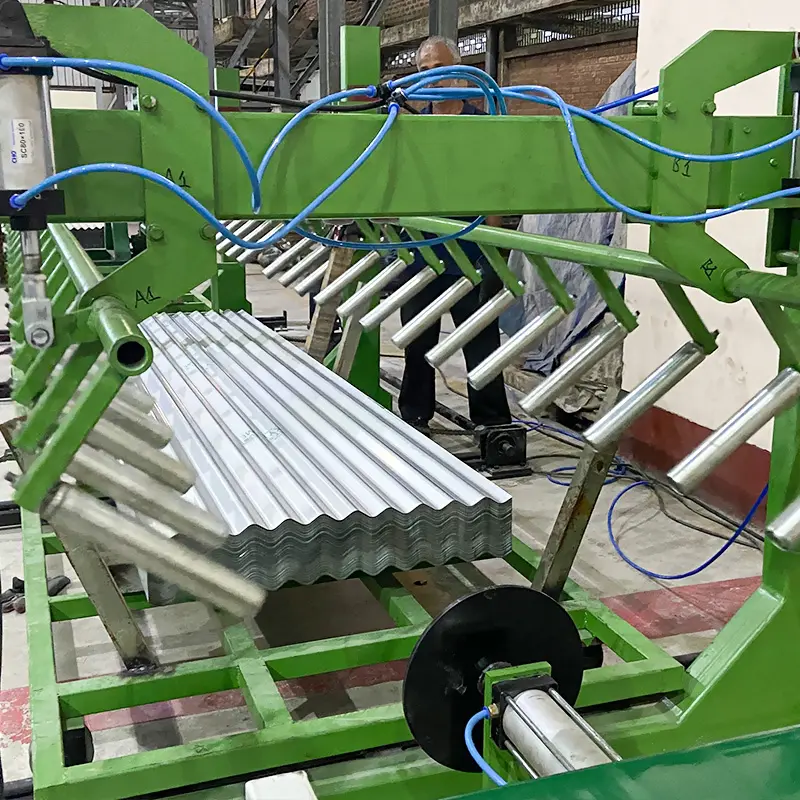

Shutter door roll forming machines work by feeding a continuous metal strip through a series of rollers that gradually bend and shape the metal into the desired shape for the shutter door. The machine is computer-controlled, which ensures a high level of precision and consistency in the shaping and cutting of the metal.

Compared to traditional manufacturing methods, shutter door roll forming machines offer several key advantages. One of the most significant advantages is speed. Shutter door roll forming machines can produce shutter doors quickly and efficiently, with the ability to produce up to 60 feet of material per minute. This can significantly reduce project timelines and labor costs.

Another advantage of shutter door roll forming machines is precision. The computer-controlled technology used in these machines ensures a high level of accuracy in the shaping and cutting of the metal, resulting in a more precise finished product. This precision also helps to ensure a more secure fit between the shutter door panels, reducing the risk of leaks or other issues.

Customization is another advantage of shutter door roll forming machines. These machines can be customized to produce shutter doors of different sizes, shapes, and materials. This makes them a versatile option for a wide range of applications, from small commercial buildings to large industrial warehouses.

Overall, shutter door roll forming machines offer several key advantages over traditional manufacturing methods, including speed, precision, and customization. By using these machines, manufacturers can produce high-quality shutter doors quickly and efficiently, helping to reduce project timelines and labor costs.

Traditional Shutter Door Manufacturing

-

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Cable Ladder Roll Forming Machine

Cable Ladder Roll Forming Machine -

PV Mounting Bracket C Shape Profile Roll Forming Machine

PV Mounting Bracket C Shape Profile Roll Forming Machine -

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine -

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile)

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile) -

PV Mounting Bracket Z Shape Profile Roll Forming Machine

PV Mounting Bracket Z Shape Profile Roll Forming Machine -

Solar mounting strut channel roll forming machine

Solar mounting strut channel roll forming machine -

Strut Channel Roll Forming Machine

Strut Channel Roll Forming Machine

Traditional shutter door manufacturing methods involve cutting, welding, and assembling individual pieces of metal to create the final product. This process requires a high level of skill and can be time-consuming, leading to higher labor costs and longer project timelines.

One advantage of traditional shutter door manufacturing methods is that they can be more cost-effective for smaller projects or for creating custom designs. This is because the equipment and materials required for traditional manufacturing methods are often more readily available and affordable for smaller-scale projects.

However, traditional manufacturing methods can be slower and less precise than shutter door roll forming machines. Welding and assembly require skilled labor and can be time-consuming, leading to longer project timelines and higher labor costs. Additionally, the quality of the finished product can vary depending on the skill level of the workers involved, leading to inconsistencies and potential issues such as leaks or gaps in the shutter door panels.

Another disadvantage of traditional manufacturing methods is that they can be less customizable than shutter door roll forming machines. Because each piece of metal is cut and assembled individually, it can be difficult to create shutter doors that are unique in size or shape.

Overall, traditional shutter door manufacturing methods can be cost-effective for smaller projects or custom designs, but they can be slower, less precise, and less customizable than shutter door roll forming machines.

Comparison of shutter door roll forming machines and traditional manufacturing methods

When comparing shutter door roll forming machines to traditional manufacturing methods, several factors should be considered, including cost, speed, quality, and customization.

- Cost: Shutter door roll forming machines can be more expensive to purchase initially, but they can save money in the long run by reducing labor costs and improving efficiency. Traditional manufacturing methods may be more cost-effective for smaller projects or custom designs.

- Speed: Shutter door roll forming machines can produce shutter doors quickly and efficiently, with the ability to produce up to 60 feet of material per minute. Traditional manufacturing methods can be slower and require more skilled labor, leading to longer project timelines.

- Quality: Shutter door roll forming machines offer a high level of precision and consistency in the shaping and cutting of the metal, resulting in a more precise finished product. Traditional manufacturing methods may produce variations in quality depending on the skill level of the workers involved.

- Customization: Shutter door roll forming machines offer a high degree of customization, allowing manufacturers to produce shutter doors of different sizes, shapes, and materials. Traditional manufacturing methods may be less customizable and may require more specialized equipment and skills for custom designs.

Overall, shutter door roll forming machines offer significant advantages in terms of speed, precision, and customization, while traditional manufacturing methods may be more cost-effective for smaller projects or custom designs. Ultimately, the choice between these two methods will depend on the specific needs of the project, including the size and scope of the project, the desired level of customization, and the available resources and budget.

Cost-Benefit Analysis of shutter door roll forming machines versus traditional manufacturing methods

When considering the cost-benefit analysis of shutter door roll forming machines versus traditional manufacturing methods, several factors should be taken into account. These include the cost of equipment and labor, the cost of materials, and the impact on project timelines.

- Cost of equipment and labor: Shutter door roll forming machines can be more expensive to purchase initially, with prices ranging from tens of thousands to hundreds of thousands of dollars. However, the machines can save money in the long run by reducing labor costs and improving efficiency. Traditional manufacturing methods may require more skilled labor, leading to higher labor costs.

- Cost of materials: The cost of materials can be similar for both shutter door roll forming machines and traditional manufacturing methods, as both methods typically use the same materials. However, because shutter door roll forming machines can produce less waste and more precise cuts, there may be less waste and a lower cost for materials.

- Impact on project timelines: Shutter door roll forming machines can produce shutter doors quickly and efficiently, with the ability to produce up to 60 feet of material per minute. This can significantly reduce project timelines and labor costs. Traditional manufacturing methods can be slower and may require more time for assembly and welding, leading to longer project timelines and higher labor costs.

Overall, while shutter door roll forming machines may have a higher initial cost, they can ultimately save money in the long run by reducing labor costs and improving efficiency. Additionally, they can produce less waste and improve project timelines, leading to further cost savings. However, traditional manufacturing methods may be more cost-effective for smaller projects or custom designs. The decision to use shutter door roll forming machines versus traditional manufacturing methods will ultimately depend on the specific needs of the project and available resources.

Shutter door roll forming machines offer significant advantages over traditional manufacturing methods. They can produce shutter doors quickly and efficiently, with a high level of precision and consistency. While traditional manufacturing methods may be more cost-effective for smaller projects or custom designs, shutter door roll forming machines can ultimately save money in the long run by reducing labor costs, improving efficiency, and improving project timelines. Ultimately, the decision to use shutter door roll forming machines versus traditional manufacturing methods will depend on the specific needs of the project and available resources.