Roll forming machines are essential equipment in many manufacturing industries, used for shaping metal sheets into various profiles and shapes. Like any machinery, roll forming machines require regular maintenance to ensure optimal performance and prevent downtime. Failure to properly maintain these machines can result in costly repairs, decreased productivity, and even safety hazards.

Maintenance tasks such as cleaning, lubricating, and inspecting the machine can help prevent wear and tear, reduce the risk of breakdowns, and extend the lifespan of the equipment. However, the maintenance requirements of roll forming machines can vary depending on factors such as the type of machine, the frequency of use, and the environment in which it operates.

Therefore, it is essential for businesses to establish a regular maintenance schedule and train operators on proper use and maintenance practices. By doing so, they can ensure that their roll forming machines are running smoothly and efficiently, and minimize the risk of unexpected downtime and costly repairs.

Daily Maintenance Checklist of Roll Forming Machine

Here is a sample daily maintenance checklist for roll forming machines that operators can follow:

- Check oil levels: Make sure that the oil levels are within the recommended range. Top up the oil if necessary.

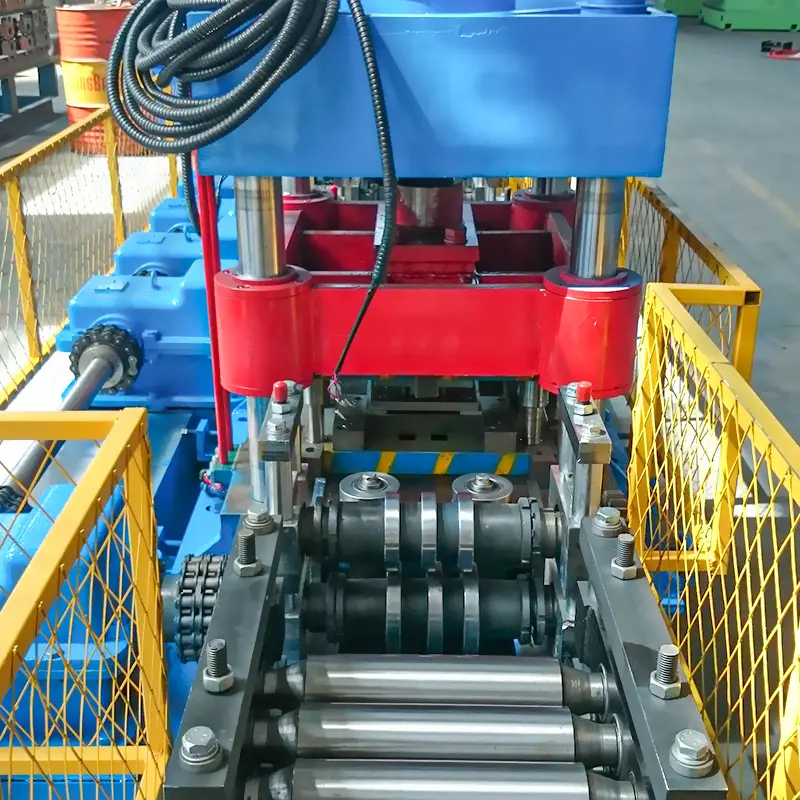

- Inspect for signs of wear and tear: Check for any signs of wear and tear, such as cracks, rust, or damaged components. Report any abnormalities to the maintenance team.

- Tighten loose bolts: Inspect the machine for any loose bolts or fasteners and tighten them if necessary.

- Clean the machine: Wipe down the machine and remove any debris or dust that may have accumulated. Pay special attention to the rollers, guides, and other moving parts.

- Lubricate moving parts: Apply lubricant to the rollers, guides, and other moving parts to prevent friction and wear.

- Check safety features: Verify that all safety features, such as emergency stop buttons and guards, are working correctly.

- Record maintenance activities: Keep a log of all maintenance activities performed, including any abnormalities or issues identified.

By following this daily maintenance checklist, operators can help ensure that the roll forming machine is running smoothly and efficiently, and reduce the risk of unexpected downtime or breakdowns. It is important to train operators on the proper use and maintenance of the machine to ensure that the checklist is followed consistently and correctly.

weekly Maintenance Checklist of Roll Forming Machine

Here is a sample weekly maintenance checklist for roll forming machines that covers more in-depth maintenance tasks:

- Clean the machine: Thoroughly clean the machine, including the rollers, guides, and other moving parts. Use a degreaser or cleaning solution if necessary.

- Lubricate moving parts: Apply lubricant to all moving parts, including the rollers, guides, and chains. Check for any parts that need additional lubrication.

- Inspect electrical system: Check the electrical system for any loose wires, damaged cables, or signs of wear and tear. Inspect the control panel and other electrical components.

- Check belts and pulleys: Inspect belts and pulleys for any signs of wear and tear or damage. Tighten loose belts or replace them if necessary.

- Inspect bearings: Inspect all bearings for any signs of wear and tear or damage. Replace any damaged bearings.

- Check alignment: Verify that the machine is properly aligned and that all components are in their correct positions.

- Test safety features: Test all safety features, including emergency stop buttons and safety guards, to ensure that they are working correctly.

- Record maintenance activities: Keep a log of all maintenance activities performed, including any abnormalities or issues identified.

By following this weekly maintenance checklist, operators can help ensure that the roll forming machine is running smoothly and efficiently, and reduce the risk of unexpected downtime or breakdowns. It is important to train operators on the proper use and maintenance of the machine to ensure that the checklist is followed consistently and correctly. Regular maintenance can help extend the lifespan of the machine and reduce repair costs over time.

Monthly Maintenance Checklist of Roll Forming Machine

Here is a sample monthly maintenance checklist for roll forming machines that covers more comprehensive maintenance tasks:

- Inspect for worn parts: Check for any parts that are showing signs of wear and tear, including rollers, guides, chains, and bearings. Replace any worn or damaged parts.

- Check and replace filters: Inspect all filters, including air and oil filters, and replace them if they are dirty or clogged.

- Inspect hydraulic system: Check the hydraulic system for any signs of leaks, damage, or wear and tear. Replace any damaged or worn components.

- Inspect pneumatic system: Check the pneumatic system for any leaks, damage, or wear and tear. Replace any damaged or worn components.

- Verify calibration: Verify that the machine is properly calibrated and that it is producing the correct profiles and dimensions.

- Inspect safety systems: Inspect all safety systems, including guards, interlocks, and emergency stop buttons, to ensure that they are functioning correctly.

- Check electrical connections: Inspect all electrical connections, including cables, wires, and connectors, for any signs of wear and tear or damage. Tighten any loose connections.

- Record maintenance activities: Keep a log of all maintenance activities performed, including any abnormalities or issues identified.

By following this monthly maintenance checklist, operators can help ensure that the roll forming machine is running smoothly and efficiently, and reduce the risk of unexpected downtime or breakdowns. It is important to train operators on the proper use and maintenance of the machine to ensure that the checklist is followed consistently and correctly. Regular maintenance can help extend the lifespan of the machine and reduce repair costs over time.

In summary, the article highlights the importance of regular maintenance for roll forming machines to ensure optimal performance and prevent costly downtime. The article provides detailed checklists for daily, weekly, and monthly maintenance tasks that operators can follow to keep their machines running smoothly. By establishing a regular maintenance schedule and training operators on proper use and maintenance practices, businesses can minimize the risk of unexpected breakdowns and extend the lifespan of their equipment, ultimately saving time and money.

Frequently Asked Questions (FAQ)

1) How often should a roll forming machine be recalibrated?

- For high-volume lines, verify calibration weekly and perform a full dimensional calibration monthly or after any tooling changeover, collision, or bearing replacement.

2) What lubricants are recommended for roll forming machine maintenance?

- Use OEM-specified EP gear oils for gearboxes (typically ISO VG 150–220), lithium-complex grease (NLGI 2) for bearings, and compatible micro-lubricants for strip if required. Avoid mixing brands/chemistries.

3) Which leading indicators predict unplanned downtime?

- Rising motor current at steady load, increased strip edge burrs, temperature spikes at stands, growing cut-length variation, vibration at specific harmonics, and particulate levels in hydraulic oil above ISO 4406 limits.

4) How do ambient conditions affect maintenance intervals?

- Dusty or humid environments accelerate contamination and corrosion—tighten cleaning, filtration, and inspection intervals by 25–50%, add desiccant breathers, and use sealed bearings where feasible.

5) What’s the best way to document Roll Forming Machine Maintenance?

- Use a CMMS with digital checklists, QR-coded assets, photo uploads, and automatic meter readings (runtime, cycles). Tie maintenance records to coil lot and tooling set IDs for traceability.

2025 Industry Trends

- Predictive maintenance standardization: Low-cost IIoT sensors (vibration, thermal, current) and edge analytics reduce reactive maintenance.

- Energy-aware maintenance: IE5 motors and regenerative drives paired with condition-based lubrication cut kWh/ton and extend component life.

- Rapid SMED practices: Preset cassettes and digital torque/position logs shorten mechanical adjustments and reduce post-changeover defects.

- Cleaner hydraulics: Offline filtration and varnish mitigation (ion-exchange resins) extend valve life and reduce stick-slip in cutoff units.

- Safety by design: STO drives, interlocked guards, and e-PTW (electronic permit-to-work) integrated into HMIs.

Roll forming maintenance KPIs and 2025 benchmarks

| KPI | 2022 Typical | 2025 Best-in-class | Practical target for SMEs |

|---|---|---|---|

| Planned vs. unplanned maintenance (%) | 60/40 | 85/15 | 75/25 |

| Mean time between failures (MTBF, hours) | 300–600 | 900–1,400 | 600–800 |

| First-pass yield after changeover (%) | 92–95 | 98–99.5 | 96–98 |

| Energy intensity (kWh/ton) | 120–160 | 80–110 | 95–125 |

| Hydraulic oil cleanliness (ISO 4406) | 20/18/15 | 17/15/12 | 18/16/13 |

| Cut length capability (mm over 10 m) | ±2.0 | ±0.5–1.0 | ±1.0–1.5 |

Selected references and data sources:

- ISO 4406 contamination codes: https://www.iso.org

- ISO 50001 energy management: https://www.iso.org

- The Fabricator (roll forming maintenance): https://www.thefabricator.com

- NIST MEP (maintenance best practices): https://www.nist.gov/mep

Latest Research Cases

Case Study 1: Predictive Vibration Analytics Cuts Unplanned Stops (2025)

Background: A North American HVAC ducting plant experienced gearbox failures every 7–9 months on a 18-stand line.

Solution: Installed triaxial accelerometers and temperature sensors on critical stands; implemented envelope analysis and bearing defect frequency alarms tied to a CMMS.

Results: MTBF increased from 520 to 1,180 hours; unplanned downtime dropped 38%; spare parts inventory reduced 22% with no stockouts.

Case Study 2: Hydraulic Cleanliness Program Improves Cutoff Accuracy (2024)

Background: A European metal framing producer saw drift in flying-shear length accuracy after 3,000 operating hours.

Solution: Added offline filtration cart (β2000 at 3 μm), varnish removal, desiccant breathers, and quarterly oil analysis with ISO 4406 targets.

Results: Cut length variation improved from ±1.8 mm to ±0.9 mm over 10 m; valve sticking incidents fell to zero; oil change interval extended by 50%.

Expert Opinions

- Dr. Daniel Schaeffler, President, Engineering Quality Solutions

Viewpoint: “Edge quality and lubrication are maintenance issues as much as process issues. Poor strip prep and contaminated lubricants accelerate roll wear and create downstream dimensional instability.” - Katey Odgen, Director of Manufacturing Engineering, MetalForming Inc.

Viewpoint: “In 2025, the fastest ROI comes from digitizing maintenance—sensorizing critical stands, linking alarms to a CMMS, and enforcing SMED checklists after every changeover.” - Prof. Katsuhiro Nakajima, Institute of Industrial Science, University of Tokyo

Viewpoint: “Non-contact metrology and thermal imaging should be part of routine maintenance. Small thermal deviations at stands predict alignment and bearing problems before vibration rises.”

Practical Tools/Resources

- CMMS platforms: UpKeep (https://www.upkeep.com), Fiix (https://www.fiixsoftware.com)

- Condition monitoring: SKF Enlight ProCollect (https://www.skf.com), Fluke vibration/thermal tools (https://www.fluke.com)

- Oil analysis and filtration: Pall (https://www.pall.com), Parker Hannifin (https://www.parker.com)

- Standards and guidance: ISO 4406, ISO 55001 asset management (https://www.iso.org)

- Training: The Fabricator—roll forming maintenance guides (https://www.thefabricator.com), ASM International tribology resources (https://www.asminternational.org)

- SPC/quality: NIST SPC resources (https://www.nist.gov)

Last updated: 2025-10-20

Changelog: Added 5 maintenance-focused FAQs; inserted 2025 maintenance KPI table and trends; provided two recent maintenance case studies; compiled expert opinions; curated practical tools/resources aligned with Roll Forming Machine Maintenance

Next review date & triggers: 2026-04-15 or earlier if new ISO/IEC standards on machinery safety or oil cleanliness are released, major OEMs adopt default predictive maintenance packages, or energy regulations affect motor/VFD specifications