Investing in a high-end roller machine can be a big decision for any business. While the upfront cost may seem daunting, the potential benefits of increased productivity and quality can make the investment worthwhile. However, it’s important to weigh both the pros and cons before making a final decision. In this post, we will explore the potential advantages and disadvantages of investing in a high-end roller machine, and help you determine whether the price is justified for your business.

why consider investing in a High-End Roller Machine?

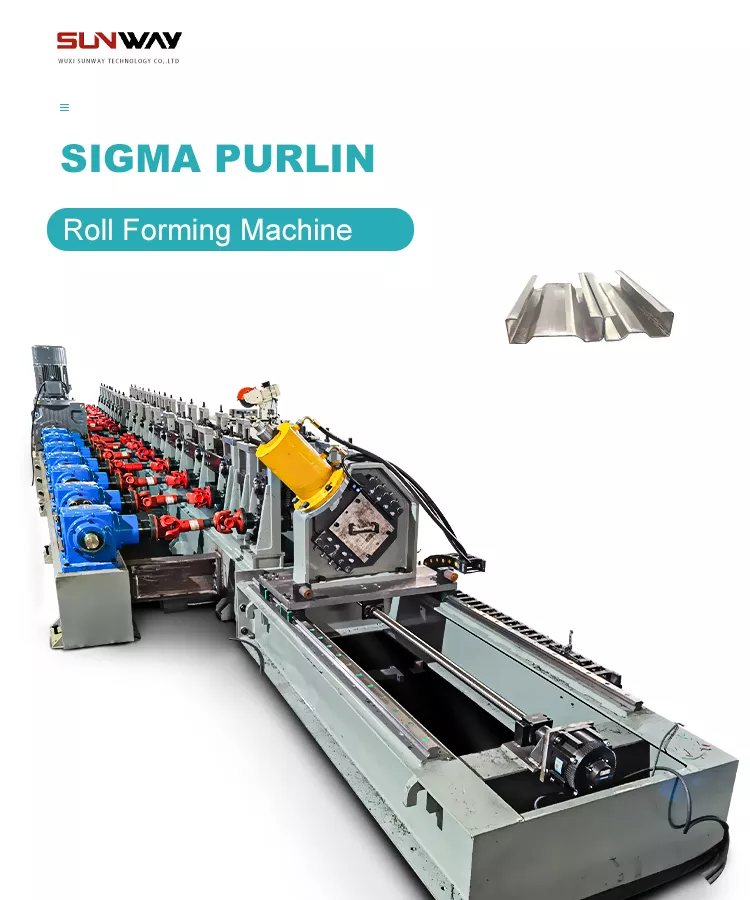

A high-end roller machine is a heavy-duty piece of equipment that is designed to apply pressure to materials in order to flatten, shape, or smooth them. These machines are typically used in manufacturing settings, but they can also be found in smaller businesses, such as print shops or woodworking shops.

One reason someone might consider investing in a high-end roller machine is because it can increase productivity and efficiency. With the ability to apply consistent pressure to materials, a roller machine can speed up production and help reduce errors or mistakes. Additionally, these machines can often handle a wider range of materials and thicknesses than other types of equipment, which can increase the versatility of your business.

Another reason someone might consider investing in a high-end roller machine is because of the potential for improved quality. By applying precise pressure to materials, a roller machine can create a smoother and more even finish than might be possible with other equipment. This can be especially important for businesses that are focused on producing high-quality products or materials.

Overall, a high-end roller machine can be a valuable investment for businesses that rely on consistent and precise pressure applications. While the initial cost may be high, the potential benefits in terms of productivity and quality can make the investment worthwhile.

pros of Investing in a High-End Roller Machine

- Increased productivity: High-end roller machines can often handle larger volumes of materials at a faster rate, resulting in increased productivity and potentially higher profits for the business.

- Improved quality: By applying consistent pressure, high-end roller machines can produce more consistent and higher-quality products, which can lead to greater customer satisfaction and loyalty.

- Versatility: High-end roller machines can often handle a wider range of materials and thicknesses, making them a versatile tool for businesses with a variety of production needs.

- Reduced labor costs: With the ability to handle larger volumes of materials at a faster rate, businesses may be able to reduce their labor costs by requiring fewer operators or reducing the need for overtime.

- Potential for cost savings: While the upfront cost of a high-end roller machine may be high, the potential for cost savings over time can be significant. By increasing productivity and reducing labor costs, businesses may be able to recoup their investment and even save money in the long run.

In conclusion, investing in a high-end roller machine can provide many benefits for businesses, including increased productivity, improved quality, versatility, and potential cost savings over time. While there are certainly some drawbacks to consider, businesses should carefully weigh the pros and cons based on their specific needs and circumstances before making a decision. Ultimately, a high-end roller machine can be a valuable long-term investment for businesses that rely on consistent and precise pressure applications.

Cons of Investing in a High-End Roller Machine

-

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Cable Ladder Roll Forming Machine

Cable Ladder Roll Forming Machine -

PV Mounting Bracket C Shape Profile Roll Forming Machine

PV Mounting Bracket C Shape Profile Roll Forming Machine -

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine -

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile)

PV Mounting Bracket Roll Forming Machine (HAT / Omega Profile) -

PV Mounting Bracket Z Shape Profile Roll Forming Machine

PV Mounting Bracket Z Shape Profile Roll Forming Machine -

Solar mounting strut channel roll forming machine

Solar mounting strut channel roll forming machine -

Strut Channel Roll Forming Machine

Strut Channel Roll Forming Machine

- High cost: One of the biggest drawbacks to investing in a high-end roller machine is the high cost. These machines can be significantly more expensive than lower-end models, making them a large investment for any business. This can be a major barrier for smaller businesses or those with limited budgets.

- Maintenance costs: Along with the initial cost, high-end machines may also require more expensive maintenance or repair work, which can add to the overall cost of ownership.

- Training and expertise: High-end machines may require more specialized training or expertise to operate effectively. This can be a challenge for businesses that don’t have experienced operators or that are looking to train new employees.

- Limited flexibility: While high-end machines may offer more customization options, they may also have limited flexibility in terms of the materials they can handle. This can be a concern for businesses that need to work with a wide range of materials or that may need to adjust their production process over time.

- Risk: Finally, investing in a high-end roller machine can come with some level of risk. While the benefits may be significant, there is always the possibility that the machine won’t meet expectations or won’t be used as much as anticipated. This can lead to a lower return on investment or even a loss.

In summary, while there are certainly advantages to investing in a high-end roller machine, there are also some potential drawbacks that should be considered. Businesses should carefully weigh the pros and cons before making a decision, taking into account factors such as their budget, production needs, and long-term goals. Ultimately, investing in a high-end roller machine can be a good choice for some businesses, but it’s important to make an informed decision based on your specific needs and circumstances.

Is the Price Justified?

Determining whether the price of a high-end roller machine is justified ultimately depends on a variety of factors, including the specific needs and goals of the business, available budget, and long-term plans. While the potential benefits of a high-end machine can be significant, the upfront cost can be a major barrier for many businesses.

To make this decision, it’s important to weigh the potential benefits and drawbacks against the cost and the expected return on investment. Businesses should consider factors such as the volume and types of materials they will be working with, the level of precision required for their products, and the potential for increased productivity and cost savings over time.

Additionally, businesses may want to explore alternatives to investing in a high-end roller machine, such as renting or leasing a machine or using a lower-cost model and upgrading later if needed. These options can provide more flexibility and lower upfront costs, but may not offer the same level of performance or long-term value as a high-end machine.

Overall, the decision to invest in a high-end roller machine should be based on a careful consideration of all the factors involved. While the price may be a significant investment, the potential benefits in terms of increased productivity, improved quality, and cost savings over time may make it a worthwhile investment for some businesses.

In conclusion, investing in a high-end roller machine can provide many benefits for businesses, including increased productivity, improved quality, versatility, and potential cost savings over time. While there are certainly some drawbacks to consider, businesses should carefully weigh the pros and cons based on their specific needs and circumstances before making a decision. Ultimately, the decision to invest in a high-end roller machine should be based on a careful consideration of all the factors involved, and businesses should explore alternatives and assess the expected return on investment before making a final decision.