Features

The C shaped purlin formed by C purlin roll forming machine has excellent anti-bending property and are easy to install. Machine adopt cast iron structure, which will increase the strength of the machine.

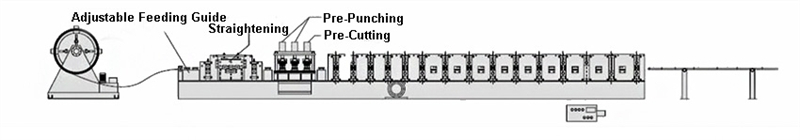

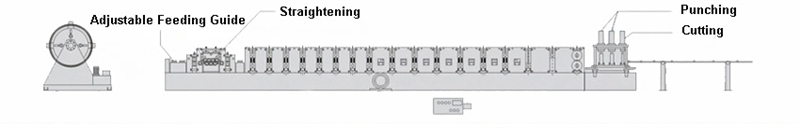

The processing of Punching & Cutting has different type for choosing: Post-Punching & Post-Cutting, Pre-Punching & Post Cutting, Pre-Punching & Pre-Cutting.

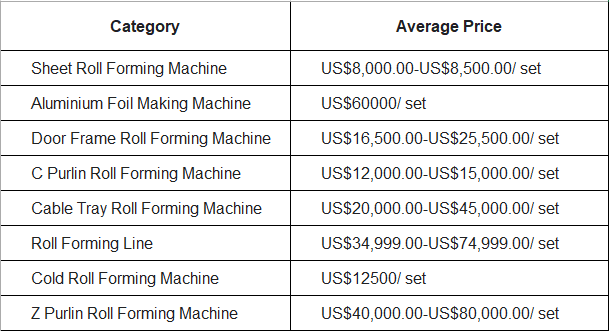

C purlin roll forming machine price:

Applications

The finished products are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on.

Process Flow

Uncoiler — Feeding — Straightening — Pre-punching — Pre-cutting — Roll Forming — Exit Rack

Uncoiler — Feeding — Straightening — Roll Forming — Post Punching — Post Cutting — Exit Rack

Machine Configurations

| 1. Hydraulic Uncoiler |

2. Feeding Device

|

| 3. Straightening |

4. Roll Forming Machine

|

| 5. Punching | 6. Cutting |

| 7. PLC Control System | 8. Exit Rack |

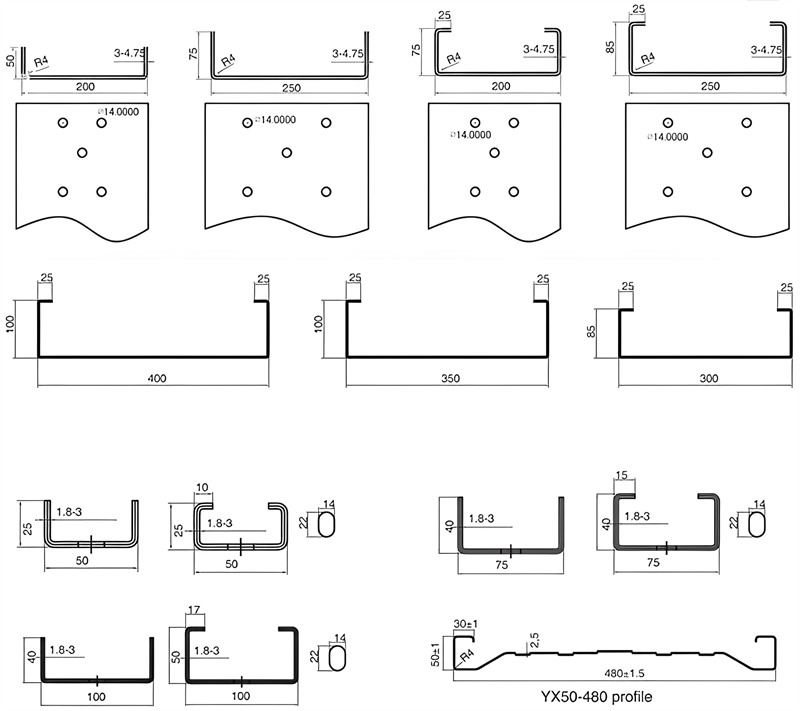

Profile Drawings for Reference

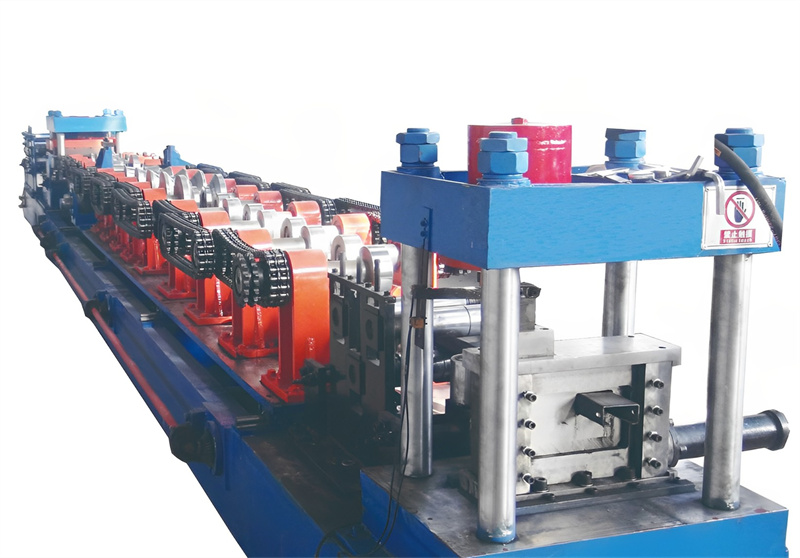

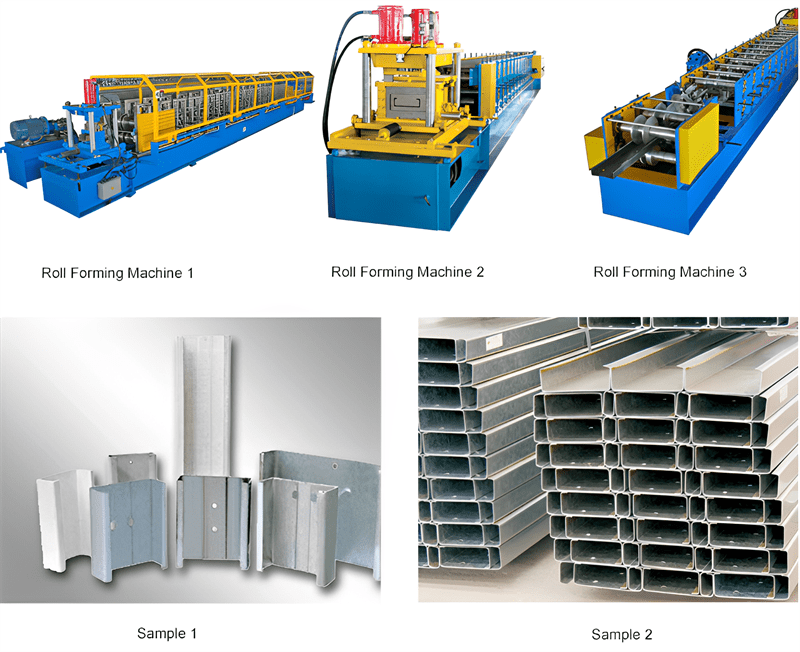

Photos for Reference

what is automatic c purlin roll forming machine?

An automatic C purlin roll forming machine is a specialized industrial machine used for manufacturing C-shaped purlins. Purlins are horizontal structural components used in construction to provide support to roof panels or walls. They are typically made from steel or other metals and are formed into a specific shape, such as C, Z, or U, to provide strength and rigidity to the structure.

The automatic C purlin roll forming machine operates by continuously feeding a coil of steel or metal strip into the machine. The machine then processes the strip through a series of rollers and dies, gradually forming it into the desired C-shaped profile. The process may involve multiple stages of forming, cutting, punching, and other operations to create the final product.

The automation aspect of the machine refers to its ability to perform these operations automatically, with minimal manual intervention. It is equipped with various sensors, controllers, and computerized systems that ensure precise measurements, consistent quality, and efficient production. The machine can typically be programmed to produce purlins of different sizes and specifications, allowing for flexibility in manufacturing.

By using an automatic C purlin roll forming machine, manufacturers can streamline their production processes, increase efficiency, and reduce labor costs. These machines are widely used in the construction industry, where there is a demand for high-quality purlins in large quantities.

application of c purlin roll forming machine?

- Roofing Systems: C purlins are commonly used to provide structural support to roof panels. They are installed horizontally across the roof, forming a framework to which the roof panels are attached. The roll forming machine is used to manufacture C purlins of the required size and specifications, ensuring precise dimensions and consistent quality.

- Wall Systems: C purlins can also be used in wall systems to provide structural support and reinforcement. They are installed vertically between wall panels and can help enhance the strength and stability of the walls. The roll forming machine is utilized to produce C purlins that match the specific requirements of the wall system.

- Industrial Sheds and Warehouses: C purlins find extensive use in the construction of industrial sheds and warehouses. These structures require robust and reliable support systems, and C purlins offer an efficient solution. The roll forming machine enables the production of C purlins in large quantities, meeting the demands of industrial-scale projects.

- Agricultural Buildings: C purlins are commonly used in agricultural buildings such as barns, poultry houses, and storage facilities. They provide structural support for the roofs and walls of these buildings. The roll forming machine allows for the efficient and cost-effective manufacturing of C purlins, catering to the specific requirements of agricultural construction.

- Infrastructure Projects: C purlins can also be used in various infrastructure projects such as bridges, walkways, and support structures. Their versatility and structural strength make them suitable for diverse applications in infrastructure development. The roll forming machine plays a crucial role in producing high-quality C purlins for these projects.

what abour c purlin roll forming machine price?

As an AI language model, I don’t have access to real-time pricing information. However, to get an accurate and up-to-date price for a C purlin roll forming machine, I recommend contacting various suppliers or manufacturers directly. They can provide you with specific pricing details based on your requirements, such as the desired machine specifications, production capacity, and additional features you may need.

It’s also worth considering that pricing for roll forming machines often involves additional costs, such as shipping, installation, training, and after-sales support. These factors should be taken into account when evaluating the overall cost of the machine.

To get the best price and ensure a reliable purchase, it’s advisable to request quotes from multiple suppliers, compare their offerings, and consider factors such as machine quality, warranty, customer reviews, and the supplier’s reputation in the industry.

does c shape purlin roll forming machine and c purlin roll forming machine are same machine?

Yes, “C shape purlin roll forming machine” and “C purlin roll forming machine” refer to the same type of machine. The term “C shape” is used to describe the profile of the purlin being formed, which is in the shape of the letter “C”. Therefore, both terms are used interchangeably to describe the machine that is specifically designed to manufacture C-shaped purlins.

A Roll Forming Machine For C Purlin: What It Is And How It Works?