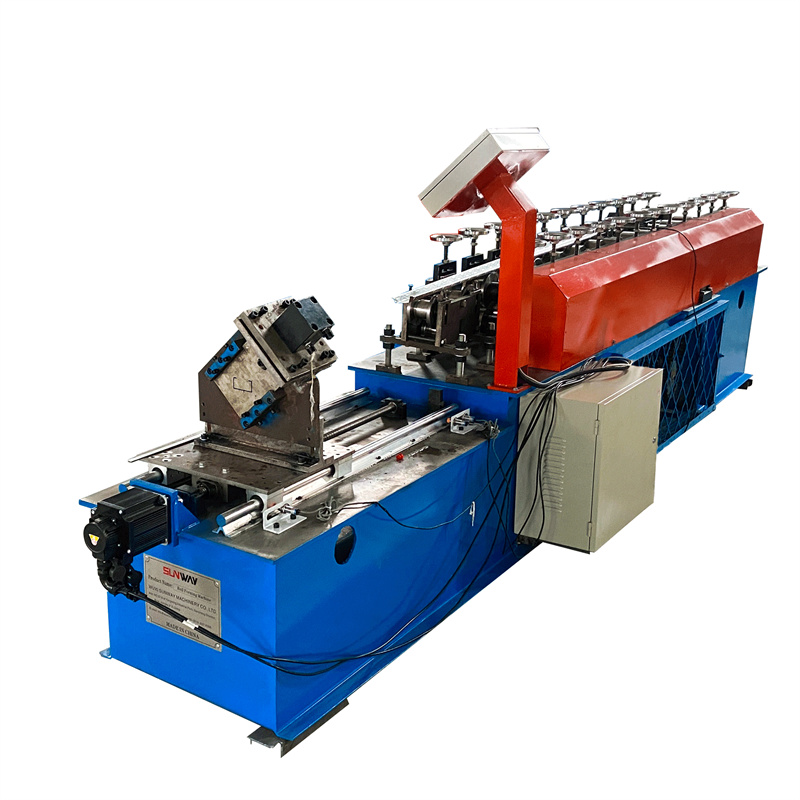

The construction industry is highly competitive, and companies are constantly looking for ways to reduce costs, increase productivity, and improve profitability. One of the ways to achieve these goals is by maximizing the efficiency of the equipment used in the production process, including Light Steel Roll Forming Machines.

Light Steel Roll Forming Machines are essential tools in the construction industry for producing high-quality, lightweight structures. However, to remain competitive, it is important to ensure that these machines are operating at peak efficiency. By doing so, companies can reduce waste, improve product quality, increase production speed, and reduce labor costs.

In this comprehensive guide, we will explore various methods to maximize the efficiency of Light Steel Roll Forming Machines, including equipment upgrades, material handling optimization, maintenance and cleaning, workflow optimization. By implementing these methods, construction companies can improve their efficiency, reduce costs, and increase their profitability.

Equipment Upgrades of Light Steel Roll Forming Machines

Upgrading equipment is a crucial step in maximizing the efficiency of Light Steel Roll Forming Machines. Here are some benefits of upgrading equipment to improve efficiency:

- Increased Speed: Newer equipment is often designed to operate at higher speeds, allowing for faster production and increased output.

- Reduced Downtime: Older equipment may require more frequent repairs and maintenance, resulting in more downtime. Upgrading to newer equipment can reduce downtime and improve productivity.

- Improved Product Quality: Newer equipment often has improved features and capabilities that can enhance the quality of the finished product. This can lead to higher customer satisfaction and repeat business.

- Energy Efficiency: Newer equipment is often designed to be more energy-efficient, reducing energy consumption and costs.

- Automation: Upgrading to automated equipment can reduce labor costs, improve accuracy, and increase productivity.

- Modern Features: Newer equipment often includes modern features such as touchscreen displays, improved safety features, and remote monitoring capabilities, making it easier to operate and maintain.

Overall, upgrading equipment is a smart investment that can significantly improve the efficiency and productivity of Light Steel Roll Forming Machines. By increasing speed, reducing downtime, improving product quality, and implementing energy-efficient and modern features, construction companies can stay competitive and improve their profitability.

Material Handling of Light Steel Roll Forming Machines

Material handling is an essential aspect of maximizing the efficiency of Light Steel Roll Forming Machines. Here are some tips for optimizing material handling:

- Use Automated Systems: Automated systems, such as conveyor belts, can help move materials quickly and efficiently through the production process, reducing the need for manual labor and improving productivity.

- Organize Storage: Proper organization of storage can help minimize downtime and make it easier to locate and retrieve materials. Using labeled shelves, bins, and racks can help keep materials organized and easy to access.

- Reduce Waste: Minimizing waste can help reduce material costs and improve efficiency. By implementing lean manufacturing principles and improving the accuracy of measurements, companies can reduce waste and improve profitability.

- Monitor Inventory Levels: Keeping track of inventory levels is crucial to ensure that there is enough material to meet production demands. Regular inventory checks can help prevent delays and downtime due to insufficient supplies.

- Use Ergonomic Equipment: Using ergonomic equipment can help reduce the risk of injury and fatigue among workers, improving their efficiency and productivity.

- Train Workers: Proper training of workers on material handling techniques and safety procedures can help prevent accidents and reduce downtime.

By optimizing material handling, companies can minimize downtime, reduce waste, and improve the efficiency of Light Steel Roll Forming Machines. By using automated systems, organizing storage, reducing waste, monitoring inventory levels, using ergonomic equipment, and training workers, companies can ensure that the production process runs smoothly and efficiently.

Maintenance and Cleaning of Light Steel Roll Forming Machines

Regular maintenance and cleaning are critical to preventing downtime and prolonging the lifespan of Light Steel Roll Forming Machines. Here are some reasons why maintenance and cleaning are essential:

- Prevent Downtime: Regular maintenance and cleaning can help prevent unexpected downtime due to machine breakdowns or malfunctions. By keeping the machine in good condition, companies can avoid costly repairs and reduce production delays.

- Extend Machine Lifespan: Proper maintenance and cleaning can help extend the lifespan of Light Steel Roll Forming Machines. By keeping the machine in good working order, companies can avoid the need for premature replacements, reducing costs in the long run.

- Ensure Optimal Performance: Regular maintenance and cleaning can help ensure that the machine is operating at optimal performance levels. This can help improve production efficiency, reduce waste, and improve product quality.

- Maintain Safety: Regular maintenance and cleaning can help ensure that the machine is operating safely. By identifying and repairing potential safety hazards, companies can avoid accidents and injuries.

- Compliance with Regulations: Regular maintenance and cleaning can help ensure compliance with regulations and standards, such as OSHA regulations and ISO certifications.

Overall, regular maintenance and cleaning are crucial to preventing downtime, extending machine lifespan, ensuring optimal performance, maintaining safety, and complying with regulations. By following manufacturer guidelines and best practices, companies can keep Light Steel Roll Forming Machines in good condition and maximize their efficiency and profitability.

Workflow Optimization of Light Steel Roll Forming Machines

Workflow optimization is critical to maximizing the efficiency of Light Steel Roll Forming Machines. Here are some reasons why workflow optimization is important:

- Lean Manufacturing: Implementing lean manufacturing principles can help eliminate waste, reduce costs, and improve efficiency. By analyzing the production process and identifying areas for improvement, companies can streamline workflows and improve productivity.

- Reduce Bottlenecks: Identifying and addressing bottlenecks in the production process can help reduce delays and downtime. By streamlining workflows and improving communication between operators, companies can avoid production backups and ensure that the machine operates at optimal levels.

- Improve Communication: Improving communication between operators can help reduce errors and improve efficiency. Clear communication can help ensure that everyone is on the same page, reducing the risk of misunderstandings and delays.

- Standardize Processes: Standardizing processes can help improve consistency and reduce the risk of errors. By establishing standard operating procedures and guidelines, companies can ensure that every operator follows the same process, reducing the risk of variation and improving quality.

- Data Analysis: Collecting and analyzing data on the production process can help identify areas for improvement and optimize workflows. By monitoring key performance indicators, such as production speed and downtime, companies can identify trends and make data-driven decisions to improve efficiency.

Overall, optimizing workflows is crucial to maximizing the efficiency of Light Steel Roll Forming Machines. By using lean manufacturing principles, reducing bottlenecks, improving communication, standardizing processes, and analyzing data, companies can improve productivity, reduce costs, and improve profitability.

In conclusion, maximizing the efficiency of Light Steel Roll Forming Machines is essential to improving productivity, reducing costs, and increasing profitability in the construction industry. Upgrading equipment, optimizing material handling, regular maintenance and cleaning, workflow optimization, and operator training are all important steps in achieving maximum efficiency. By implementing these methods and continuously looking for areas of improvement, construction companies can improve the production process, reduce waste, and deliver high-quality structures in a cost-effective and timely manner.