Light steel is becoming increasingly popular in the construction industry due to its strength, durability, and versatility. To create light steel structures, Light Steel Roll Forming Machines are used. A Light Steel Roll Forming Machine is a type of equipment used in the manufacturing industry to produce light steel profiles. It works by shaping and forming steel into the desired profile using a series of rollers.

The importance of Light Steel Roll Forming Machines in the construction industry cannot be overstated. These machines have revolutionized the way light steel structures are produced, making the process more cost-effective and reliable than ever before. By using a Light Steel Roll Forming Machine, construction companies can produce high-quality light steel structures efficiently, quickly, and with minimal waste.

In this comprehensive guide, we will explore the various components of a Light Steel Roll Forming Machine, the types of light steel profiles that can be produced. We will also provide tips for maintenance and safety to ensure your machine continues to operate at peak efficiency. So, let’s dive in!

Machine Components that make up Light Steel Roll Forming Machines

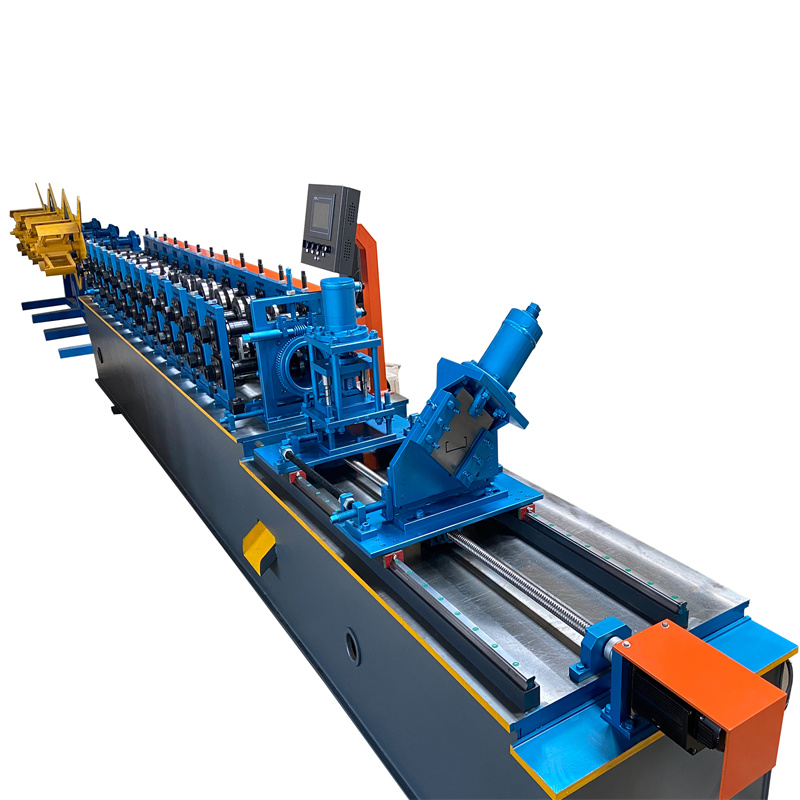

A Light Steel Roll Forming Machine is composed of several components that work together to shape and form steel into the desired profile. The following are the main components of a Light Steel Roll Forming Machine:

- Decoiler: This is the device that holds the steel coil in place and feeds it into the machine. The decoiler can be either manual or motorized and is designed to handle different weights and sizes of steel coils.

- Feeding System: The feeding system ensures that the steel is fed through the machine at a consistent speed. It consists of rollers and guides that guide the steel through the machine.

- Roll Forming System: The roll forming system is the heart of the Light Steel Roll Forming Machine. It consists of a series of rollers that gradually shape and form the steel into the desired profile. The rollers are typically arranged in pairs and are designed to be adjustable to accommodate different profiles.

- Cutting System: Once the steel has been formed into the desired profile, it is cut to the required length using a cutting system. The cutting system can be either a flying cut-off system, which cuts the steel while it’s still moving through the machine, or a stationary cut-off system, which cuts the steel once it has exited the machine.

- Control System: The Light Steel Roll Forming Machine is controlled by a computerized control system that monitors and adjusts various parameters, such as the speed of the feeding system, the pressure of the rollers, and the position of the cutting system. This ensures that the machine produces consistent, high-quality profiles.

Overall, a Light Steel Roll Forming Machine is a complex piece of equipment that consists of several components working together to shape and form steel into the desired profile. Each component is essential to the machine’s operation and plays a critical role in ensuring that the final product meets the required specifications.

Types of Light Steel Profile that Light Steel Roll Forming Machines can produce

Light Steel Roll Forming Machines can produce a wide range of light steel profiles, each with its unique characteristics and advantages. The following are some of the different types of light steel profiles that can be manufactured using a roll forming machine:

- C Profiles: C profiles are used primarily for structural framing applications. They are often used as horizontal supports in walls, roofs, and floors.

- U Profiles: U profiles are used as vertical supports or framing members in walls and roofs. They are often used in conjunction with C profiles for added stability.

- Z Profiles: Z profiles are commonly used as purlins or girts in metal buildings. They are designed to resist bending and can support heavy loads.

- L Profiles: L profiles are used as brackets, supports, or framing members. They are often used in building construction, furniture, and shelving applications.

- Sigma Profiles: Sigma profiles are used for structural framing applications in residential and commercial construction. They have a unique shape that provides excellent stability and strength.

- Hat Profiles: Hat profiles are used as framing members or as channels to hold wiring or plumbing. They are often used in building construction and electrical applications.

Overall, Light Steel Roll Forming Machines can produce a wide range of light steel profiles to meet various application requirements. The type of profile produced will depend on the materials used and the specific needs of the project.

Maintenance and Upkeep of Light Steel Roll Forming Machines

Proper maintenance and upkeep of a Light Steel Roll Forming Machine are essential to ensure its longevity and efficiency. Here are some tips for maintaining and cleaning the machine:

- Regular Inspection: Inspect the machine regularly to ensure that all components are working correctly. Check for loose or worn parts, and replace them immediately.

- Lubrication: Keep all moving parts lubricated to prevent wear and tear. Use the recommended lubricants and follow the manufacturer’s guidelines.

- Cleaning: Clean the machine regularly to remove any debris or dirt that may accumulate. Use a soft cloth and mild detergent to avoid damaging the machine’s components.

- Tighten Loose Bolts: Check for any loose bolts or screws and tighten them to prevent them from falling out or causing damage.

- Replace Worn Components: Replace worn components, such as rollers or blades, as soon as possible to avoid damaging the machine or producing substandard profiles.

- Proper Storage: Store the machine in a dry and clean environment when not in use to avoid rust and other types of corrosion.

- Operator Training: Train the machine operators on how to use the machine correctly and safely. Ensure they follow the manufacturer’s guidelines and procedures.

In summary, regular maintenance and cleaning of a Light Steel Roll Forming Machine are critical to ensure its longevity and efficiency. Following the manufacturer’s guidelines and procedures, inspecting and lubricating the machine, and cleaning it regularly are all essential steps to keep the machine working correctly. Finally, operator training and awareness are critical to ensure the safe and proper operation of the machine.

guidelines for safe operation of Light Steel Roll Forming Machines

Safety is paramount when operating a Light Steel Roll Forming Machine. It is essential to take precautions to prevent accidents and injuries. Here are some guidelines for safe operation:

- Protective Equipment: Wear personal protective equipment, such as gloves, safety glasses, and earplugs, to protect against flying debris, noise, and other hazards.

- Training: Provide proper training to all light steel roll forming machine operators on the safe operation of the machine. Ensure they understand the potential hazards and know how to handle emergency situations.

- Secure the Area: Keep the area around the light steel roll forming machine clean and clear of debris. Secure loose clothing and remove any jewelry or other items that could get caught in the machine.

- Lockout/Tagout: Use lockout/tagout procedures to ensure that the machine is not turned on or operated during maintenance or repair activities.

- Electrical Safety: Ensure that the machine is properly grounded and that all electrical connections are secure. Avoid using damaged electrical cords or plugs.

- Avoid Overloading: Do not overload the machine with too much material, as this can cause the machine to malfunction or damage the material.

- Emergency Stop: Make sure the machine has an emergency stop button that is easily accessible and that all operators know how to use it.

- Maintenance and Upkeep: Follow proper maintenance and cleaning procedures to ensure that the machine is functioning correctly and safely.

In summary, it is essential to prioritize safety when operating a Light Steel Roll Forming Machine. Proper training, protective equipment, and adherence to safety guidelines can prevent accidents and injuries. Always be aware of potential hazards and take precautions to mitigate risks. By following these guidelines, operators can ensure that the machine operates safely and efficiently.

In conclusion, Light Steel Roll Forming Machines play a vital role in the construction industry by providing a cost-effective, efficient, and reliable method of producing light steel profiles. By understanding the different components, types of profiles, roll forming process, and maintenance and safety guidelines, operators can maximize the efficiency and longevity of the machine while ensuring the safety of all personnel involved. Light Steel Roll Forming Machines are versatile and can produce a wide range of profiles to meet the diverse needs of the construction industry. They are an essential tool for the production of high-quality, lightweight structures.