A light steel keel roll forming machine is a machine that’s used to form the steel sheets into a hollow, wave-like shape. This process is ideal for making stainless steel, because the result of this process is a higher quality product with less breakage and less deformity. If you want to learn more about the best way to make stainless steel with a light steel keel roll forming machine, please read on.

What is a Light Steel Keel Roll Forming Machine?

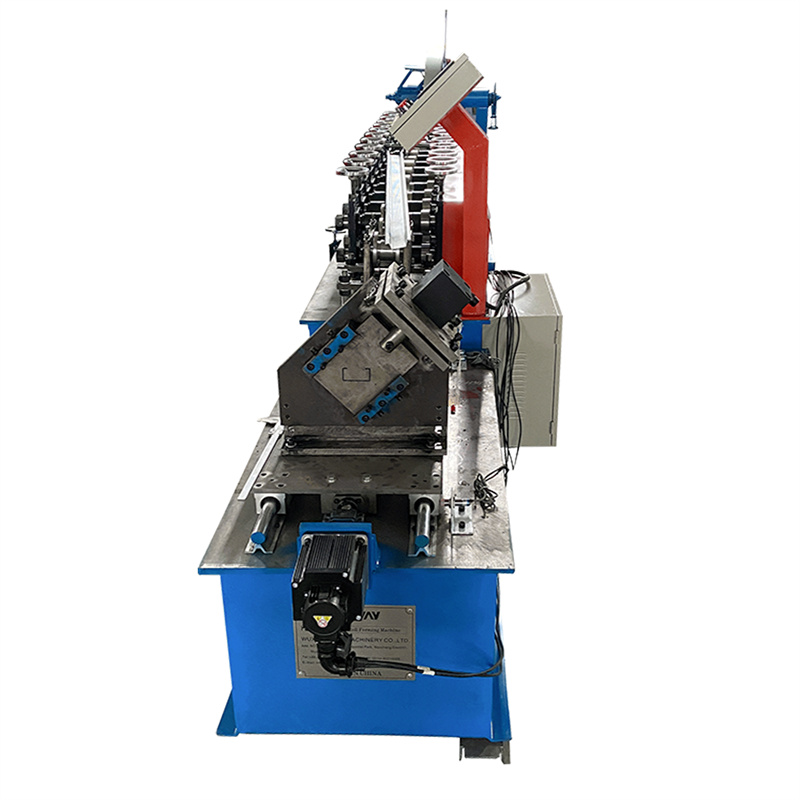

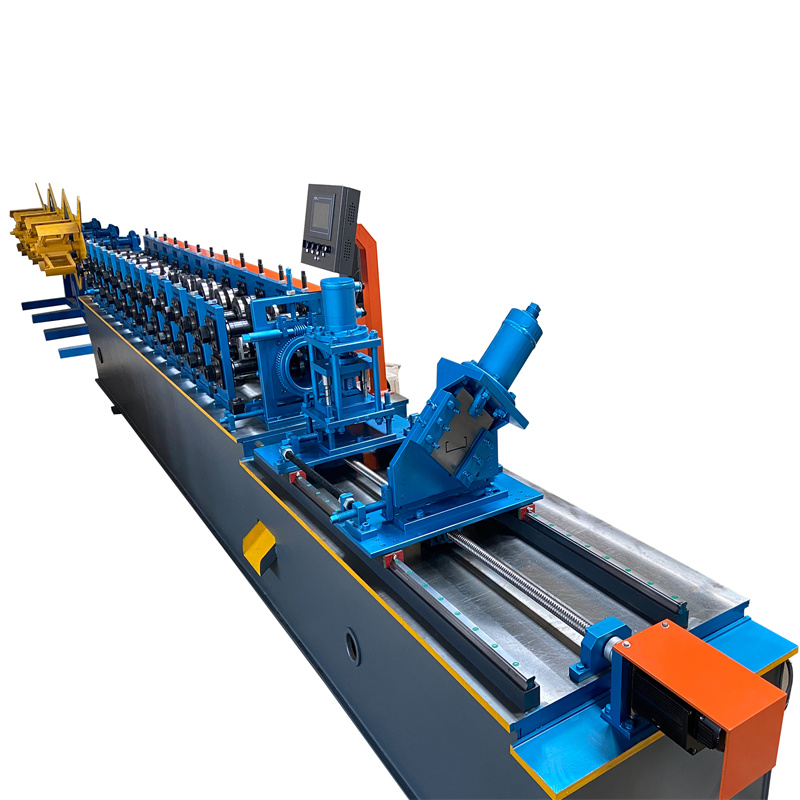

A light steel keel roll forming machine is a type of construction equipment used to create stainless steel beams and trusses. It consists of a series of rollers that press sheets of metal into the desired shape. The machine can be adjusted to create different shapes and sizes of steel members.

The light steel keel roll forming machine is a versatile piece of equipment that can be used in a variety of construction applications. It is often used to create structural support beams, trusses, and other load-bearing members. The machine is capable of creating custom shapes and sizes to meet the specific needs of the project.

The light steel keel roll forming machine is a cost-effective way to create high-quality stainless steel members. It is a fast and efficient way to produce large quantities of steel beams, trusses, and other load-bearing members.

Why is a Light Steel Keel Roll Forming Machine the best way to make stainless steel?

There are many benefits to using a light steel keel roll forming machine over other methods of stainless steel production. Perhaps the most significant benefit is the speed at which the machine can operate. A typical light steel keel roll forming machine can produce stainless steel at a rate of up to 150 meters per minute, which is much faster than other methods of production.

In addition to being fast, a light steel keel roll forming machine is also very versatile. It can be used to create a variety of different stainless steel products, including sheets, coils, and pipes. This versatility means that you can use the machine to create custom products that meet your specific needs.

Another advantage of using a light steel keel roll forming machine is that it requires less energy to operate than other methods of stainless steel production. This means that you can save money on your energy bills while still producing high-quality stainless steel products.

If you are looking for a fast, efficient, and versatile way to produce stainless steel, then a light steel keel roll forming machine is the best option for you.

-

Multi Profiles Roll Forming Machine

Multi Profiles Roll Forming Machine -

Auto Changeable C Z Purline Machine

Auto Changeable C Z Purline Machine -

Semi Auto Size Changeable CZ Purlin Roll Forming Machine

Semi Auto Size Changeable CZ Purlin Roll Forming Machine -

Laser Welding Square Pipe Roll Forming Machine

Laser Welding Square Pipe Roll Forming Machine -

Vineyard Post Roll Forming Machine

Vineyard Post Roll Forming Machine -

Scaffolding Plank Roll Forming Machine

Scaffolding Plank Roll Forming Machine -

Light Gauge Steel Roll Forming Machine

Light Gauge Steel Roll Forming Machine -

Auto Size Changeable Sigma Purlin Roll Forming Machine

Auto Size Changeable Sigma Purlin Roll Forming Machine -

Auto Size Changeable C Z Purlin Roll Forming Machine

Auto Size Changeable C Z Purlin Roll Forming Machine

How to operate a light steel keel roll forming machine?

Operating a light steel keel roll forming machine is simple and easy once you understand the basics. The first thing you need to do is make sure that the material you want to use is compatible with the machine. The next step is to load the material into the feeder, which will then send it through the rolls. After the desired shape has been achieved, the final step is to cut off the excess material.

How to choose the right light steel keel roll forming machine?

There are a few things you should keep in mind when choosing a light steel keel roll forming machine.

First, consider the type of material you’ll be using. If you’re only working with stainless steel, then you don’t need a machine that can also handle other materials.

Second, think about the thickness of the material you’ll be using. Some machines are designed for thinner materials, while others can handle thicker materials.

Third, consider the speed of the machine. Some machines are faster than others, so if you need a quick turnaround time, choose a faster machine.

Fourth, think about the size of the machine. If you have limited space, choose a smaller machine.

Finally, consider your budget. There are both expensive and less expensive options available, so choose the one that fits your needs and budget best.

What are the advantages of a light steel keel roll forming machine?

A light steel keel roll forming machine offers a number of advantages over other types of machines. First, it is much lighter in weight, making it easier to move and transport. Second, it is less likely to damage the material being rolled. Third, it is more precise, meaning that it can produce a higher quality product. Finally, it is faster and more efficient, meaning that you can produce more products in a shorter amount of time.

Conclusion

If you’re looking for a machine that can help you produce high-quality stainless steel products, then a light steel keel roll forming machine is the way to go. With this machine, you’ll be able to create products that are durable and long-lasting, which is exactly what your customers are looking for. Investing in a light steel keel roll forming machine is an investment that will pay off in the long run, so don’t hesitate to add one to your business today.