When it comes to roofing solutions, the conversation often circles around materials that offer durability, cost-effectiveness, and ease of installation. One such material that has stood the test of time is galvanized roofing sheets—specifically, corrugated iron sheets. Whether you are constructing a new building, refurbishing an old one, or simply curious about your options, understanding galv roofing sheets is crucial. This comprehensive guide will walk you through everything you need to know about these versatile roofing materials—from types and working processes to supplier comparisons and FAQs.

Overview of Galv Roofing Sheets

Galvanized roofing sheets are steel sheets coated with a layer of zinc to prevent rusting. This zinc coating, known as galvanization, offers a durable and corrosion-resistant surface, making it an ideal choice for roofing applications. The corrugated pattern not only adds to the sheet’s strength but also enhances its ability to channel water away from the roof, reducing the risk of water pooling and leakage.

Key Features of Galv Roofing Sheets:

- Durability: Long-lasting and resistant to weathering.

- Corrosion Resistance: The zinc coating protects the steel from rust.

- Lightweight: Easier to handle and install compared to traditional roofing materials.

- Cost-effective: Affordable yet reliable, making it a popular choice for budget-conscious projects.

- Versatile: Suitable for various applications, from residential to industrial buildings.

Common Applications of Galv Roofing Sheets:

- Residential buildings (e.g., houses, garages)

- Agricultural structures (e.g., barns, sheds)

- Industrial buildings (e.g., warehouses, factories)

- Commercial properties (e.g., shops, offices)

Corrugated Iron Sheets Guide

Corrugated iron sheets are a subset of galv roofing sheets, characterized by their distinctive wave-like pattern. This pattern not only adds to the aesthetic appeal of the roof but also enhances the structural integrity of the sheets, making them suitable for various load-bearing applications.

Types of Corrugated Iron Sheets:

1. G-90 Galvanized Corrugated Iron Sheet

- Description: The G-90 is a heavy-duty option, coated with 0.90 ounces of zinc per square foot. This thick coating provides exceptional resistance to rust and corrosion, making it ideal for harsh weather conditions.

- Applications: Perfect for industrial settings and coastal areas where moisture and salt air are prevalent.

2. G-60 Galvanized Corrugated Iron Sheet

- Description: With a zinc coating of 0.60 ounces per square foot, the G-60 offers a balance between cost and protection. It’s a versatile option that works well in both residential and commercial settings.

- Applications: Suitable for general-purpose roofing and siding.

3. 22-Gauge Galvanized Corrugated Iron Sheet

- Description: This sheet is slightly thinner than the G-60, making it lighter and easier to install. However, it still offers robust protection against the elements.

- Applications: Ideal for residential projects where ease of handling and installation is a priority.

4. 26-Gauge Galvanized Corrugated Iron Sheet

- Description: Even thinner than the 22-gauge, the 26-gauge sheet is incredibly lightweight and cost-effective. However, it offers less protection and is best suited for areas with mild weather conditions.

- Applications: Used in temporary structures, small sheds, and non-load-bearing applications.

5. R-Panel Galvanized Corrugated Iron Sheet

- Description: The R-Panel is a high-strength sheet with a deep corrugation profile, providing extra rigidity and load-bearing capacity. It’s commonly used in industrial and commercial settings.

- Applications: Suitable for large industrial buildings, warehouses, and factories.

6. U-Panel Galvanized Corrugated Iron Sheet

- Description: Similar to the R-Panel but with a shallower profile, the U-Panel offers a smoother appearance while still maintaining good strength.

- Applications: Popular in residential and commercial buildings for both roofing and siding.

7. 5V Crimp Galvanized Corrugated Iron Sheet

- Description: This sheet features a unique V-shaped crimp pattern, offering a distinctive look and excellent water runoff capabilities.

- Applications: Ideal for areas with high rainfall, often used in barns, homes, and outbuildings.

8. Corrugated Galvalume Sheet

- Description: A blend of aluminum and zinc coating provides superior corrosion resistance compared to standard galvanized sheets. It also offers a modern, sleek appearance.

- Applications: Suitable for modern residential buildings, commercial projects, and coastal areas.

9. Standing Seam Galvanized Corrugated Iron Sheet

- Description: This type features raised seams where the panels join, offering superior weather-tightness and a sleek, modern appearance.

- Applications: Perfect for high-end residential projects and commercial properties.

10. Box Profile Galvanized Corrugated Iron Sheet

- Description: The box profile offers a more modern alternative to the traditional wave-like corrugation, with angular ridges providing increased strength and water runoff.

- Applications: Used in both residential and commercial settings, especially in contemporary designs.

Working Process of Galv Roofing Sheets

The process of creating galvanized roofing sheets is a meticulous one, ensuring that the final product is durable, corrosion-resistant, and ready for installation. Here’s a breakdown of how these sheets are manufactured:

1. Steel Sheet Preparation

The base material, typically a steel coil, is cleaned and prepped to ensure it’s free of impurities. This preparation is crucial as any contaminants can affect the adhesion of the zinc coating.

2. Galvanization Process

The cleaned steel is then immersed in a molten zinc bath, which bonds to the surface of the steel through a metallurgical reaction. This coating process is what gives the sheets their signature corrosion-resistant properties.

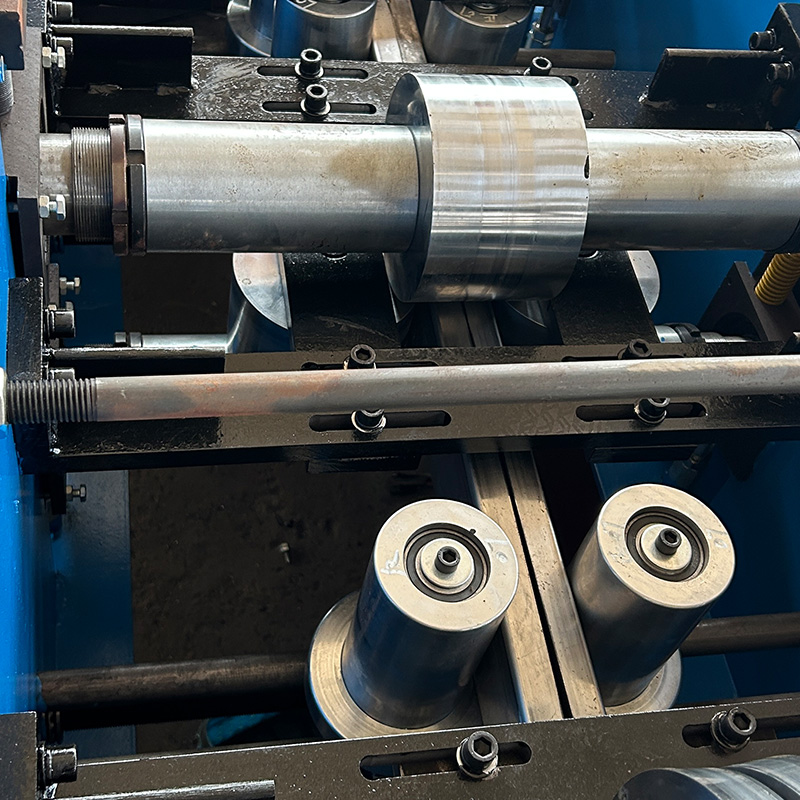

3. Corrugation

After the zinc coating has cooled and solidified, the sheets are fed through a series of rollers that form the distinctive corrugated pattern. This pattern is not just for aesthetics—it also increases the sheet’s strength and ability to handle heavy loads.

4. Cutting and Shaping

Once corrugated, the sheets are cut to the required length and shape according to the specific application they are intended for. This step can also include the addition of features like pre-punched holes for easy installation.

5. Quality Inspection

Each sheet undergoes a rigorous quality control process to ensure it meets the required standards for thickness, coating adhesion, and overall integrity. Any sheets that don’t meet these standards are discarded or recycled.

Components and Functions in Galv Roofing Sheets

Understanding the key components and their functions in galv roofing sheets is essential for anyone looking to invest in this material.

| Component | Function |

|---|---|

| Steel Base | The core structure of the sheet, providing strength and rigidity. |

| Zinc Coating | Protects the steel from corrosion and rust, significantly extending the sheet’s lifespan. |

| Corrugations | Increase the sheet’s structural integrity, allowing it to bear more weight and channel water effectively. |

| Anti-Fingerprint Layer | A protective layer that prevents smudges and fingerprints, maintaining the sheet’s appearance. |

| Paint Coating | Optional layer applied for aesthetic purposes and additional weather resistance. |

| Pre-Punched Holes | Facilitate easier and quicker installation by aligning with fasteners without the need for on-site drilling. |

| Reflective Surface | Reflects heat, keeping buildings cooler and reducing energy costs. |

| Rust Inhibitors | Additional chemicals or treatments that enhance the corrosion resistance of the zinc coating, particularly in extreme environments. |

| Seams and Joints | Where sheets overlap or connect, designed to ensure weather-tightness and structural continuity. |

-

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

Auto Size Changeable Sigma Purlin Roll Forming Machine

Auto Size Changeable Sigma Purlin Roll Forming Machine -

Auto Size Changeable C Z Purlin Roll Forming Machine

Auto Size Changeable C Z Purlin Roll Forming Machine -

Auto Size Changeable Z Purlin Roll Forming Machine

Auto Size Changeable Z Purlin Roll Forming Machine -

Auto Size Changeable C U Purlin Roll Forming Machine

Auto Size Changeable C U Purlin Roll Forming Machine -

Electrical Cabinet Frame Roll Forming Machine

Electrical Cabinet Frame Roll Forming Machine

Machine Speed and Efficiency in Galv Roofing Sheets Manufacturing

The manufacturing process for galv roofing sheets is highly optimized to ensure efficiency and precision. Below is a table that outlines the key aspects of machine speed and overall efficiency in the production process:

| Machine/Process | Speed | Efficiency |

|---|---|---|

| Roller Press | 10-20 meters per minute | High efficiency due to consistent speed and pressure, ensuring uniform corrugation patterns. |

| Zinc Coating Line | 30-40 meters per minute | Optimized for fast coating application, balancing speed with thorough zinc adhesion. |

| Cooling Line | 15-25 meters per minute | Rapid cooling to prevent zinc distortion, maintaining the sheet’s integrity and finish. |

| Cutting Machine | 5-10 sheets per minute | Precision cutting with minimal waste, ensuring consistent sheet lengths and reducing material costs. |

| Quality Control Inspection | 50-100 sheets per hour | Manual and automated inspections work together to quickly identify defects while maintaining a steady production flow. |

Customized Mechanical Parameters of Galv Roofing Sheets

Customization is key when it comes to galv roofing sheets, as different projects have different requirements. Here’s a table outlining some of the mechanical parameters that can be customized:

| Parameter | Standard Specification | Custom Options |

|---|---|---|

| Sheet Thickness | 0.4mm – 1.2mm | Can be customized based on load requirements and weather conditions. |

| Corrugation Depth | 15mm – 50mm | Deeper corrugations for increased strength in load-bearing applications. |

| Sheet Width | 600mm – 1200mm | Adjustable to fit specific roofing layouts and reduce waste. |

| Zinc Coating Thickness | 60g/m² – 275g/m² | Thicker coatings available for extreme environments, such as coastal areas. |

| Length | 1.8m – 6m | Custom lengths available to match specific project needs, reducing the number of joints and seams required. |

| Color Finish | Silver/Plain | Various colors available to match aesthetic preferences and building designs. |

| Surface Finish | Smooth/Matte | Textured finishes available for enhanced grip and visual appeal. |

| UV Protection | Standard | Additional UV-resistant coatings for areas with high sun exposure. |

| Fastener Holes | Standard pre-punched | Custom hole patterns to match unique installation requirements. |

Applications and Uses of Galv Roofing Sheets

Galv roofing sheets are incredibly versatile and can be used in a wide range of applications. Here’s a detailed look at where these sheets are commonly applied:

| Application Area | Specific Uses |

|---|---|

| Residential Buildings | Roofing, wall cladding, garages, carports, and garden sheds. |

| Agricultural Structures | Barns, grain storage, livestock shelters, and greenhouses. |

| Industrial Buildings | Factories, warehouses, and storage facilities. |

| Commercial Properties | Shops, office buildings, and retail spaces. |

| Temporary Structures | Event tents, pop-up shops, and temporary shelters. |

| Infrastructure Projects | Bridges, tunnels, and roofing for public spaces like bus stops or railway stations. |

| Sports and Recreational Facilities | Stadiums, sports halls, and gymnasiums. |

| Renovation Projects | Re-roofing old structures, adding cladding to aging buildings, and improving the thermal performance of existing roofs. |

| Coastal and High-Humidity Areas | Structures in areas prone to corrosion, such as seaside buildings and humid environments, where enhanced corrosion resistance is essential. |

| Aesthetic Designs | Used in architectural projects where the visual appearance of the corrugated pattern or custom colors play a key role in the overall design. |

Installation, Operation, and Maintenance of Galv Roofing Sheets

Proper installation and maintenance are critical to ensuring the longevity and performance of galv roofing sheets. Below is a table outlining key steps and considerations:

| Aspect | Details |

|---|---|

| Installation | Secure sheets with appropriate fasteners, ensuring they are properly overlapped to prevent water ingress. |

| Sealing Joints | Use waterproof sealants at joints and seams to enhance weather-tightness. |

| Fastener Selection | Choose rust-resistant screws or nails to match the longevity of the roofing material. |

| Ventilation | Ensure proper ventilation to prevent condensation and extend the life of the roof. |

| Regular Inspections | Inspect the roof bi-annually or after severe weather for signs of wear, corrosion, or damage. |

| Cleaning | Clean the roof periodically to remove debris, moss, or algae that could cause staining or damage. |

| Repainting | If the sheets are painted, consider repainting every 5-10 years to maintain appearance and provide additional protection. |

| Repairs | Address any damage immediately to prevent it from worsening, using matching materials and techniques. |

| Snow and Ice Management | In colder climates, ensure that snow and ice are regularly removed to prevent excess weight and potential collapse. |

| Gutter and Drainage Maintenance | Keep gutters and drainage systems clear to avoid water backup and potential roof damage. |

Suppliers and Price Range Details

When it comes to sourcing galv roofing sheets, choosing the right supplier is crucial. Here’s a comparison of suppliers and the price ranges they offer:

| Supplier | Location | Price Range (Per Square Meter) | Specialty | Customization Options |

|---|---|---|---|---|

| ABC Metal Roofing | USA | $8 – $15 | High-quality, durable sheets with custom colors. | Extensive customization, including custom lengths. |

| Global Roofing Solutions | Europe | $10 – $18 | Innovative products with advanced coatings. | UV protection and anti-fingerprint options. |

| BlueScope Steel | Australia | $12 – $20 | Trusted for long-lasting and weather-resistant sheets. | Coastal-grade zinc coatings available. |

| Tata Steel | India | $6 – $12 | Affordable solutions with reliable performance. | Standard and customized gauge options. |

| Metal Roofing Online | Online Supplier | $9 – $16 | Convenient online purchasing with fast delivery. | Wide range of profiles and finishes. |

| Kloeckner Metals | USA/Global | $10 – $19 | Leading supplier with high production standards. | Custom colors, thickness, and lengths. |

| Safintra Roofing | Africa/Asia | $7 – $13 | Focus on sustainable and energy-efficient products. | Reflective and insulated coatings available. |

| ArcelorMittal | Global | $11 – $17 | High-performance sheets for industrial applications. | Heavy-duty and high-corrosion resistance options. |

| Jindal Steel & Power | India/Global | $8 – $14 | Cost-effective and durable solutions. | Custom corrugation patterns and coatings. |

| Union Corrugating | USA | $9 – $15 | Industry leader in lightweight, easy-to-install sheets. | Pre-punched holes and fastener compatibility. |

How to Choose a Supplier for Galv Roofing Sheets

Selecting the right supplier can significantly impact the quality and cost of your roofing project. Here’s what you should consider:

1. Reputation and Reliability

Choose a supplier with a strong reputation for quality and reliability. Check customer reviews, testimonials, and industry certifications to gauge their credibility.

2. Range of Products

A good supplier should offer a wide range of products, including various gauges, coatings, and profiles, to ensure you find the perfect fit for your project.

3. Customization Options

Customization is crucial, especially for larger or more specialized projects. Ensure your supplier can provide tailored solutions such as custom lengths, colors, and coatings.

4. Pricing and Value

While price is important, it shouldn’t be the only factor. Consider the overall value, including the quality of materials, durability, and the level of customer service provided.

5. Delivery and Logistics

Efficient delivery is essential, especially for large-scale projects. Check if the supplier offers timely delivery services and how they handle logistics, especially for remote or difficult-to-reach areas.

6. Warranty and After-Sales Support

A robust warranty and reliable after-sales support are key indicators of a supplier’s confidence in their product. Make sure you understand the terms of any warranty and the availability of support services.

7. Sustainability and Environmental Impact

In today’s eco-conscious market, consider suppliers that prioritize sustainable practices, such as using recycled materials or offering energy-efficient roofing options.

Advantages and Limitations of Galv Roofing Sheets

Like any material, galv roofing sheets come with their own set of pros and cons. Here’s a detailed comparison:

| Aspect | Advantages | Limitations |

|---|---|---|

| Durability | Long-lasting with excellent resistance to rust and corrosion. | Can still rust over time, especially in highly acidic or salty environments. |

| Cost | More affordable compared to materials like aluminum or copper. | Prices can fluctuate with changes in the steel market. |

| Weight | Lightweight, making them easier to transport and install. | Less sturdy than some heavier roofing options, potentially less impact-resistant. |

| Installation | Simple and quick to install, reducing labor costs. | Requires careful handling to avoid scratches or damage during installation. |

| Maintenance | Low maintenance, with only periodic inspections and cleaning required. | Can require repainting or re-coating over time, especially in harsh climates. |

| Aesthetic Options | Available in various finishes and colors, allowing for design flexibility. | Fewer aesthetic options compared to more premium materials like slate or tile. |

| Energy Efficiency | Reflective coatings can reduce cooling costs in hot climates. | Less insulating compared to thicker roofing materials, may require additional insulation. |

| Environmental Impact | Can be recycled at the end of their life, reducing environmental waste. | Production and galvanization processes can have a significant carbon footprint. |

FAQ

| Question | Answer |

|---|---|

| What is the lifespan of galvanized roofing sheets? | Typically, they can last anywhere from 20 to 50 years, depending on the quality of the zinc coating and the environment in which they are installed. |

| Can galvanized roofing sheets rust? | While they are highly resistant to rust, they can eventually corrode if the zinc coating is compromised, especially in harsh environments like coastal areas. |

| How do I maintain galvanized roofing sheets? | Regular inspections, cleaning to remove debris, and occasional repainting or re-coating can help maintain their appearance and functionality. |

| Are galvanized sheets environmentally friendly? | They are more eco-friendly than some other options because they can be fully recycled at the end of their life cycle. |

| Can I paint galvanized roofing sheets? | Yes, they can be painted, though it’s important to use the right type of paint designed for galvanized metal to ensure good adhesion and longevity. |

| What is the difference between G-60 and G-90 galvanized sheets? | G-90 sheets have a thicker zinc coating (0.90 ounces per square foot) compared to G-60 (0.60 ounces per square foot), offering better corrosion resistance. |

| How does the thickness of the sheet affect its performance? | Thicker sheets generally offer better durability and load-bearing capacity, but they are also heavier and more expensive. |

| Can galvanized sheets be used in coastal areas? | Yes, but it’s recommended to use sheets with a higher zinc coating (like G-90) or those with additional protective coatings to withstand the salty, humid air. |

| What is the difference between corrugated and box profile sheets? | Corrugated sheets have a wavy pattern that provides good strength and flexibility, while box profile sheets have angular ridges that offer a more modern look and increased rigidity. |

| How do I choose the right type of galvanized sheet for my project? | Consider factors like climate, building type, load requirements, aesthetic preferences, and budget. Consulting with a supplier or roofing expert can also help. |

Conclusion

Galv roofing sheets, particularly corrugated iron sheets, offer an exceptional blend of durability, cost-effectiveness, and versatility. Whether you’re building a home, a barn, or an industrial complex, these sheets provide a reliable roofing solution that stands up to the elements while offering a range of customization options to meet your specific needs. By understanding the different types, working processes, and key considerations outlined in this guide, you’re well-equipped to make an informed decision that will serve you well for decades to come. Whether you’re looking for aesthetic appeal, environmental sustainability, or sheer practicality, galv roofing sheets are a tried-and-true option that won’t disappoint.